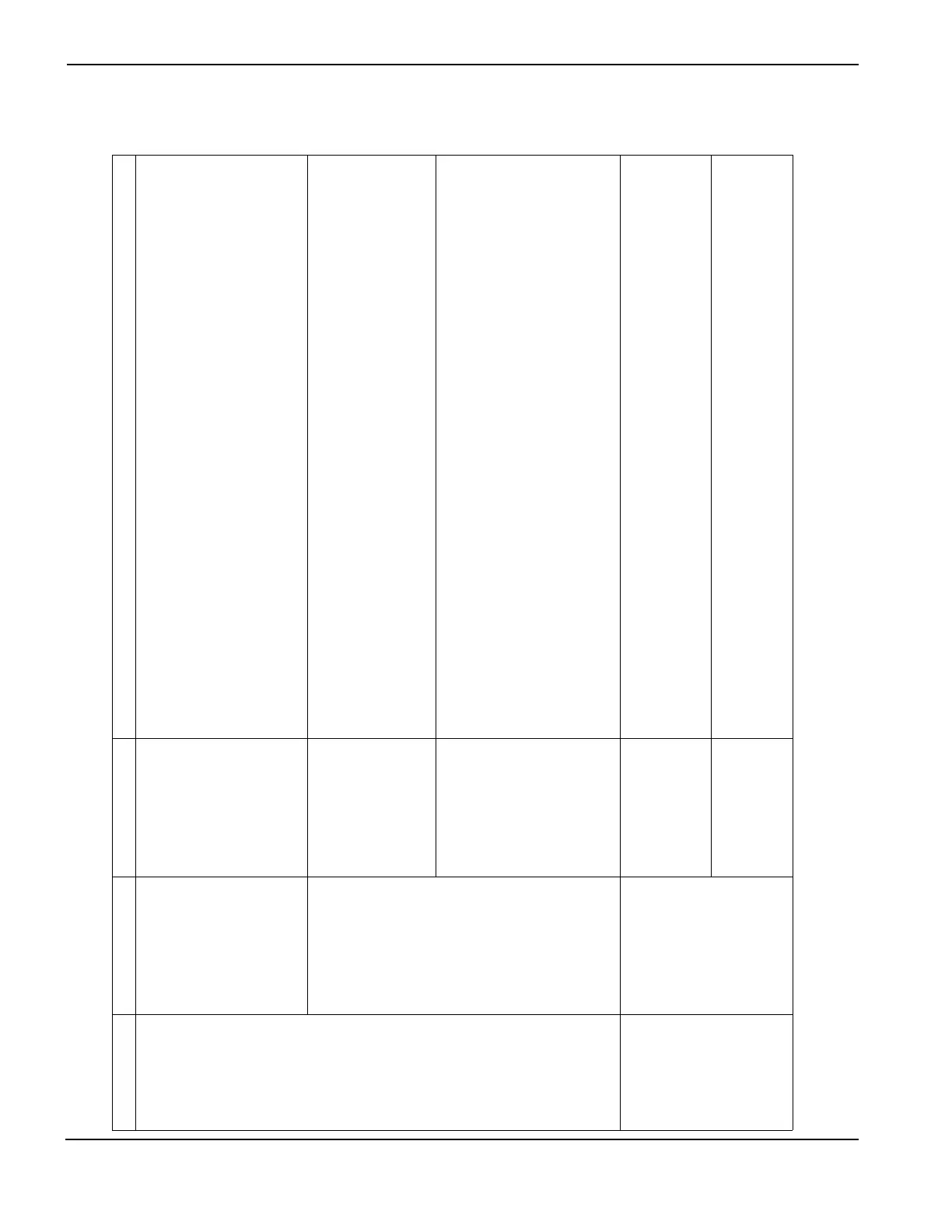

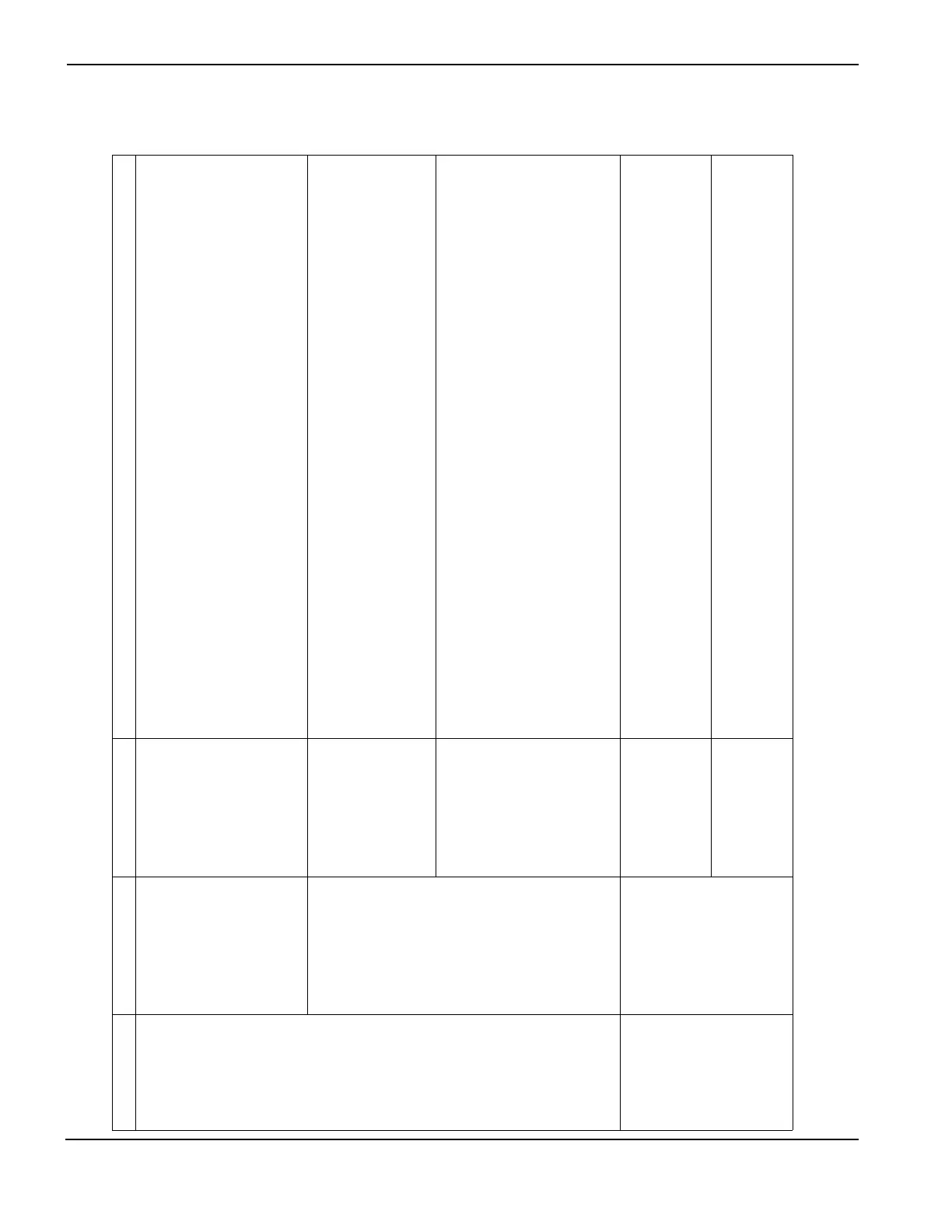

Condition Result Cause Solution

Torch rising off

plate when table

starts moving

(Continued)

Faulty voltage

divider

Refer to the cut chart in the Operation section of the manual. Determine the torch-to-

work distance for the material you are cutting. Perform a manual cut (AVC off) at the

height and travel speed indicated in the manual. If using a Command THC, monitor the

actual arc voltage on the pendant (if used) or measure the voltage on the terminal strip

in the plasma interface box (from Electrode to Work). Voltage should be +/-10 VDC

from setting shown in manual. If voltage is low check for gas leaks. If voltage is within

+/-10 VDC from book setting, then perform another manual cut and measure the

divided voltage across pins 16 and 35 on J7 in Plasma Interface Box. The voltage

should be 1/40th of actual arc voltage. If using a THC system other than the Command

THC, refer to manufacturer of the THC system to determine how to test their voltage

divider.

Gas restriction

With inlet pressures set to book values, and gas pressures set according to the cut

charts, the plasma preflow and cut-flow should be as shown in the cut charts. There are

pressure values at the bottom of each cut chart for PG1 and PG2 during cutting. All

pressures should be within +/- 5 psi (+/- 0.3 bar). If one of these pressures is high and

all gas settings are correct, then there is a restriction in the gas system after the Gas

Console. If one of these pressures is low, then there is a leak in the system or

insufficient flow from gas source.

O-ring on the center

shaft on the back of

the torch is not

properly seated

If the torch is not screwed completely onto the torch receptacle, the o-rings on the back

of the torch body will not properly seal gases and coolant when power is applied. As a

result, the force of the coolant leaking around the center shaft of the torch will cause

the o-ring to become dislodged. Refer to the Installation section of this manual for

proper installation of the quick-disconnect torch.

One of the coolant

connectors on the

back of the torch is

damaged

Inspect o-rings on back of the torch for damage. Refer to the Operation section of this

manual to identify coolant connectors.

Water Leaking

out Torch Body

Faulty voltage

divider

Refer to the cut chart in the Operation section of the manual. Determine the torch-to-

work distance for the material you are cutting. Perform a manual cut (AVC off) at the

height and travel speed indicated in the manual. If using a Command THC, monitor the

actual arc voltage on the pendant (if used) or measure the voltage on the terminal strip

in the plasma interface box (from Electrode to Work). Voltage should be +/-10 VDC

from setting shown in the manual. If voltage is high, the problem could be a gas

restriction after the Off-Valve or a faulty torch. If voltage is within +/-10 VDC from book

setting, then perform another manual cut and measure the divided voltage across pins

16 and 35 on J7 in the Plasma Interface Box. The voltage should be 1/40th of actual

arc voltage. If using a THC system other than the Command THC, refer to

manufacturer of THC system to determine how to test their voltage divider.

Torch not properly

seated to torch

receptacle

Torch moves down

toward or into the

plate when table

starts moving

THC not

functioning

properly

(Continued)

MAINTENANCE

5-14 HT4400 Instruction Manual

2

System Troubleshooting - 4 of 4

Loading...

Loading...