INSTALLATION

HT4400 Instruction Manual 3-21

2

Machine Interface Connections - 2 of 2

Cable - Machine I/O Interface to

Power Supply

Installation Notes

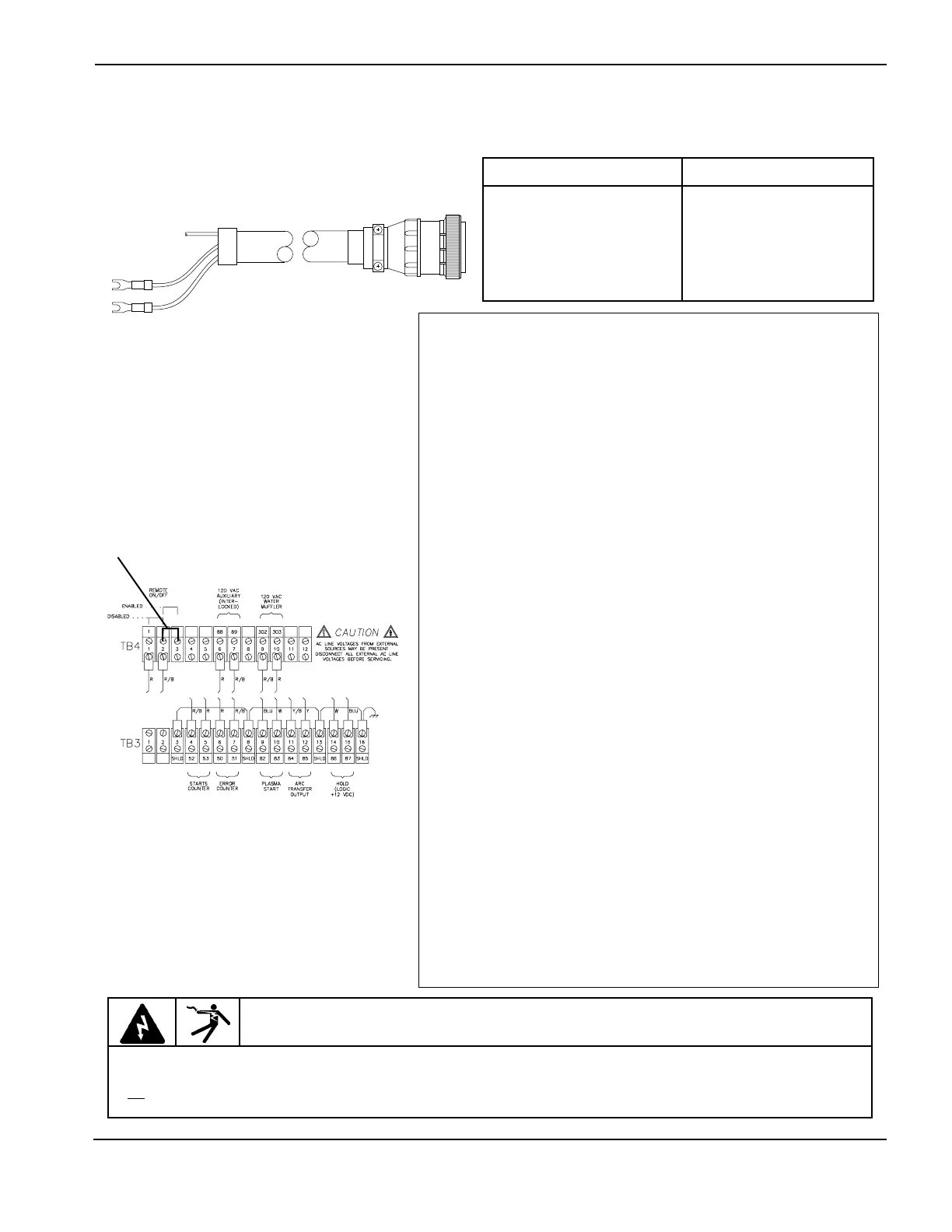

If using the Command THC, do not connect this cable.

RUN LIST – Machine I/O Interface t

Power Supply Cable

SIGNAL Terminal COLOR 1X6

Remote OFF** 78 Green 32

Remote ON** 79 Red 37

Remote ON/OFF Shield** Cut Shield 26

Hold Signal (12VDC) Signal. Closed-ON;Open=OFF 87 White 1

Hold Common 86 Black 5

Hold Shield Cut Shield 10

Plasma Start (12VDC) Signal. Closed=Start 82 Blue 9

Plasma Start Signal 83 Black 15

Plasma Start Shield Cut Shield 14

Plasma Emergency Stop (24VAC) Signal. Closed=Stop 80 Yellow 28

Plasma Emergency Stop Signal 81 Red 33

Plasma Emergency Stop Shield Cut Shield 27

Arc Xfer Output - Signal. Dry contact relay† * 84 Red 36

Arc Transfer Output - Signal* 85 Blue 31

Arc Transfer Output - Shield* Cut Shield 25

Pierce Complete*** 135 Orange 4

Pierce Complete*** 136 Black 8

Pierce Complete Shield*** Cut Shield 13

Error Counter 167 Green 35

Error Counter 168 Black 30

Error Counter Shield Cut Shield 24

Notes:

* Contact closes after arc transfer and time delay

** To enable a remote ON/OFF switch, the jumper on TB4 must be moved from

terminals 1&2 to terminals 2&3 - see figure.

*** A contact closure will activate pierce complete and keeps shield in preflow

mode. Open the contacts for shield cutflow mode.

Note on the µP PCB that resistor R150 and capacitor C78 are connected in

series across the contacts. In some cases, one lead of R150 must be cut from

the control PC board, as the R-C circuit may provide enough current flow to

maintain machine motion input to the cutting machine.

1X6

Part No. Length

123574 10 ft (3 m)

123575 15 ft (4.6 m)

123576 20 ft (6.1 m)

023892 25 ft (7.6 m)

123577 30 ft (9.2 m)

123578 40 ft (12.2 m)

023893 50 ft (15.3 m)

Part No. Length

123579 60 ft (18.3 m)

023894 75 ft (22.9 m)

023895 100 ft (30.5 m)

123089 125 ft (38.1 m)

023896 150 ft (45.8 m)

123033 175 ft (53.4 m)

023897 200 ft (61 m)

Loading...

Loading...