HT4400 Instruction Manual e-3

3

Mild Steel

O

2

Plasma / O

2

-N

2

Shield

300 Amps

Flow Rates @ 140 psi / 9.6 bar

(scfh / slh)

N

2

O

2

Preflow 194.2 / 5499 56.9 / 1611

Cutflow 173.4 / 4910 115.6 / 3273

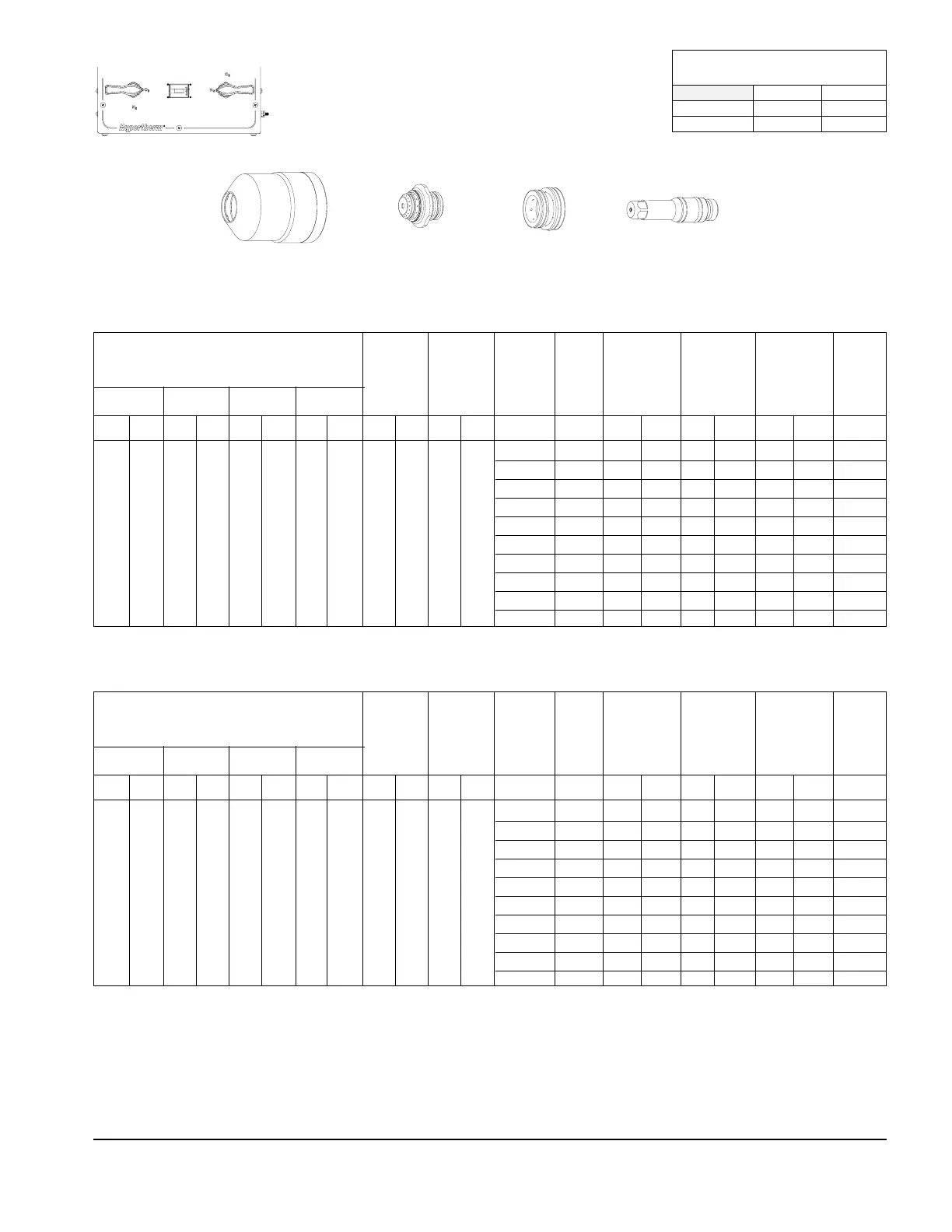

120786

Retaining Cap

120794

Nozzle

120913

Swirl Ring

120802

Electrode

* Piercing not recommended

** Cuts on these thicknesses may result in increased cut angle variation and surface roughness. Reduce cut speed by

5%-10% for improvement with some materials.

Minimum inlet pressures remain at one setting of 140 psi (9.6 bar) for all material thicknesses.

Approximate pressures while cutting in RUN mode: PG1 72

PG2 43

1/4** 120 .062 2 190 4830 .125 3 0.3

3/8** 125 .125 3 160 4060 .250 6 0.5

1/2 130 .157 4 120 3050 .314 8 0.7

5/8 135 .188 5 100 2540 .375 10 0.9

3/4 140 .188 5 80 2030 .375 10 1.1

7/8 145 .188 5 70 1780 .375 10 1.3

1 145 .188 5 55 1400 .375 10 1.5

1-1/8 150 .188 5 50 1270 * * *

1-1/4 155 .250 6 45 1140 * * *

1-1/2 155 .250 6 35 890 * * *

ENGLISH

Material

Thickness

Plasma PlasmaShield Shield

MV1 MV2 MV3 MV4 MV5 MV6 MV7 PG1 PG2 PG1 PG2 inches Volts in. mm ipm mm/m in. mm seconds

Test

Preflow

Verify

(psi)

Test

Cutflow

Verify

(psi)

Arc

Voltage

Torch-to-Work

Distance

Cutting

Speed

Initial Pierce

Height

Pierce

Delay

Time

Test Preflow and Cutflow Adjust

(psi)

47 2 8 8 13 40 40 1747 4547

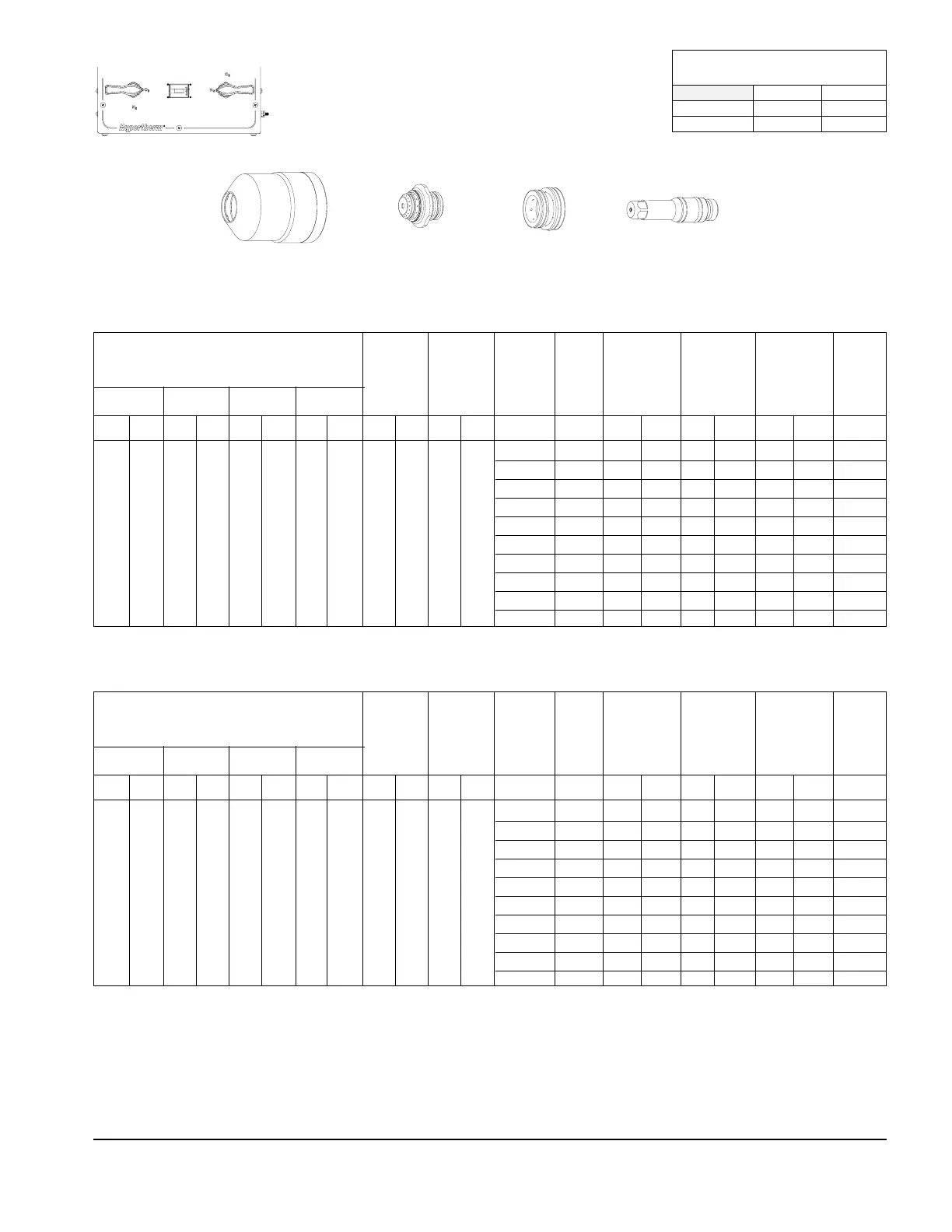

6** 120 2 .062 5108 201 3 .125 0.3

10** 125 3 .125 3871 153 6 .250 0.5

12 130 4 .157 3226 127 8 .314 0.7

15 135 5 .188 2681 106 10 .375 0.9

20 140 5 .188 1935 76 10 .375 1.1

22 145 5 .188 1796 71 10 .375 1.3

25 145 5 .188 1419 56 10 .375 1.5

30 150 5 .188 1213 48 * * *

32 155 6 .250 1134 45 * * *

35 155 6 .250 1014 40 * * *

METRIC

Material

Thickness

Plasma PlasmaShield Shield

MV1 MV2 MV3 MV4 MV5 MV6 MV7 PG1 PG2 PG1 PG2 mm Volts mm in. mm/m ipm mm in. seconds

Test

Preflow

Verify

(psi)

Test

Cutflow

Verify

(psi)

Arc

Voltage

Torch-to-Work

Distance

Cutting

Speed

Initial Pierce

Height

Pierce

Delay

Time

Test Preflow and Cutflow Adjust

(psi)

47 2 8 8 13 40 40 1747 4547

Loading...

Loading...