Operation‐InitialStartup

26

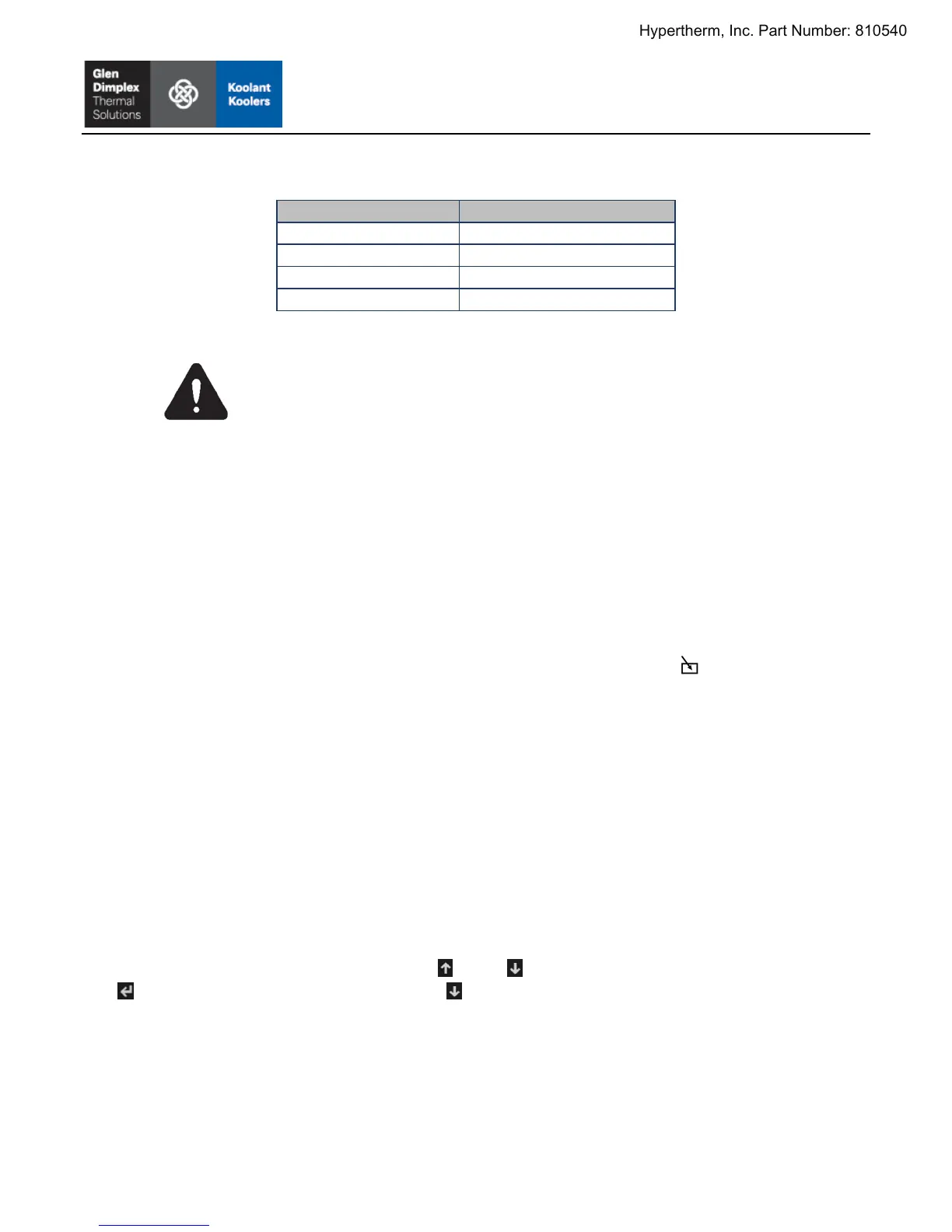

Table7:RecommendedCompressorWarm‐upTim e

DisconnectoffTime CompressorWarm‐upTime

<30min 0min

30minto2hrs 2hrs

2hrsto4hrs 4hrs

>4hrs 8hrs

CAUTION

Startingthechillerpre‐maturelywithoutallowingadequatetimeforthecompressorstowarm‐

upcanallowtheliquidrefrigeranttobepumpedthroughthecompressorlubricationsystem

andcausepermanentdamagetothecompressorbearingsandvoidthechillerwarranty.

7.2 InitialStartup

7.2.1 LocalModeStart‐up

ThechillercanbeoperatedinaLocalModewhereitoperatesindependentoftheplasmacu ttingsystem,orina

RemoteModewhereitstartsandstopsautomaticallybasedonthestateoftheRemot eStart/Stopinterlock

fromtheplasmacuttingsystem.Uponinitialstartup thechillershouldbestartedinLocalModetoche

ckout

chilleroperationindependentoftheplasmacuttingsystem.

7.2.1.1 StartingtheChillerinLocalMode

TostartthechillerturntheLocal/Off/RemoteSwitchbelowthecontrollertotheposition.Thepumps

willturnonandstartcirculatingwater.

7.2.1.2 LeakCheck

Thoroughlycheckallthep lumbinghosesandfittingsbetweenthechillerandpl

asmacuttingsystem

toensurenoleaksarepresent.

Removethefilterpa nel fromthesideofthechillerandinspecttheinternal chillerplumbingto

ensuretherearenointernalplum bingleaks.

Replacethefilterpanel.

IfanyleaksarefoundturntheLocal/Off/Remote Switchtothe“O”positionandwaitforth

epumps

toautomaticallyshutoff(Theprocesspumpshutsdownin~3sandtherecirculationpumpin~10s).

Onceanyleakshavebeenrepairedrestarttheprocedureat7.2.1LocalModeStart‐up.

7.2.1.3 ProcessPumpCheck

Fromthechillercontrollerhomescreenpressand/ortohighl

ighttheMONITORINGselection.Press

toaccesstheMONITORINGmenuandpressuntilthe“ProcessFluidCircuit”monitoringscreen

appears.Checktheprocesspump“Flow Rate”tomakesureitexceeds1.3gpm(4.92lpm)at50Hzor

2.2gpm(8.33lpm)at60Hz.Alsochecktheprocessfluidcircuitdischargepressure(“

DisPress”)toensureit

isatleast10psi(68.9kPa)belowtheshutdownpressureof240psi(1,655kPa).Theprocesspumpcircuitis

equippedwithapressurereliefbypassvalvethatissettostartopeningat190psi(1,310kPa)andfully

bypasstheflowat230psi(1,586kPa).

Hypertherm, Inc. Part Number: 810540

Loading...

Loading...