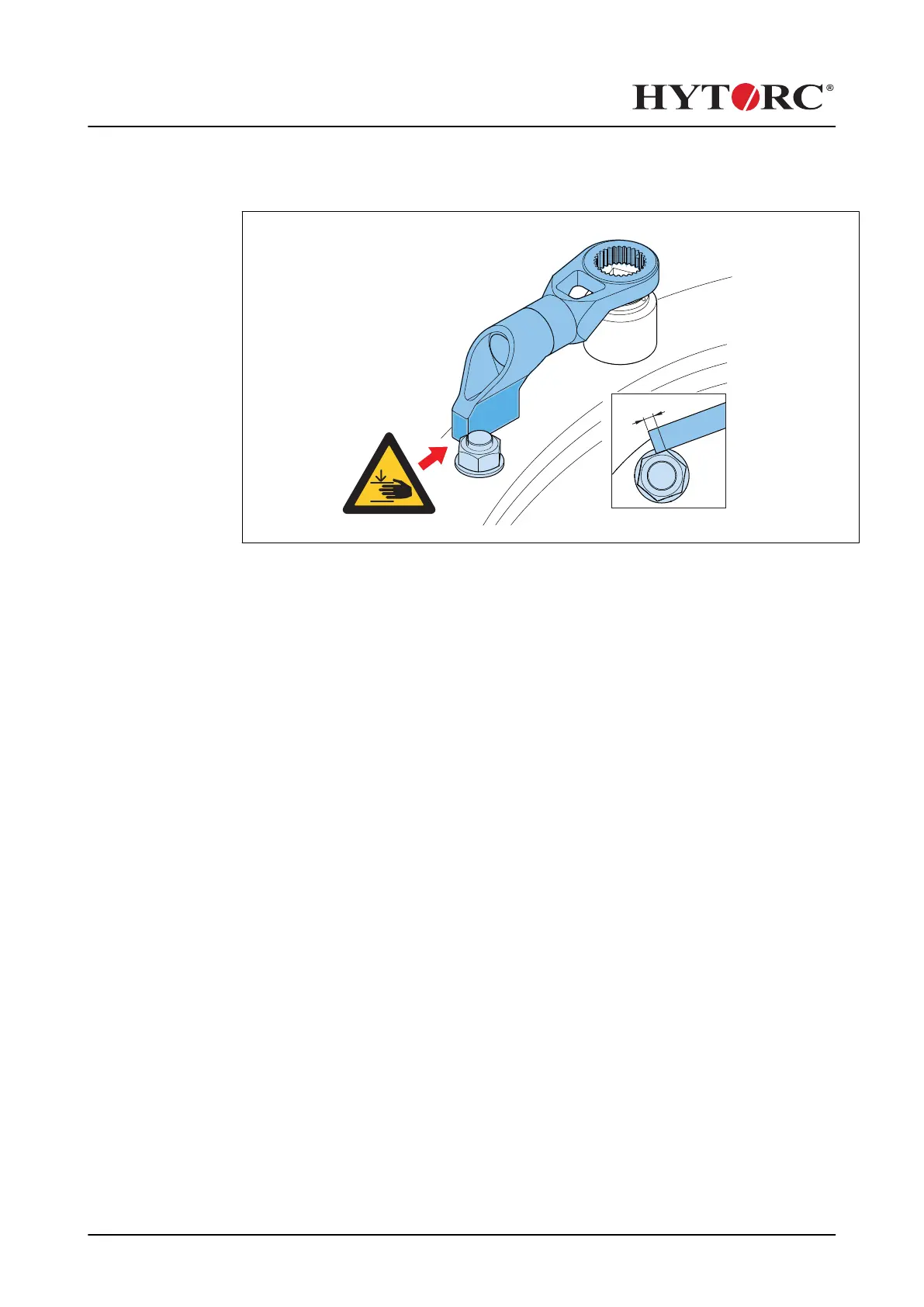

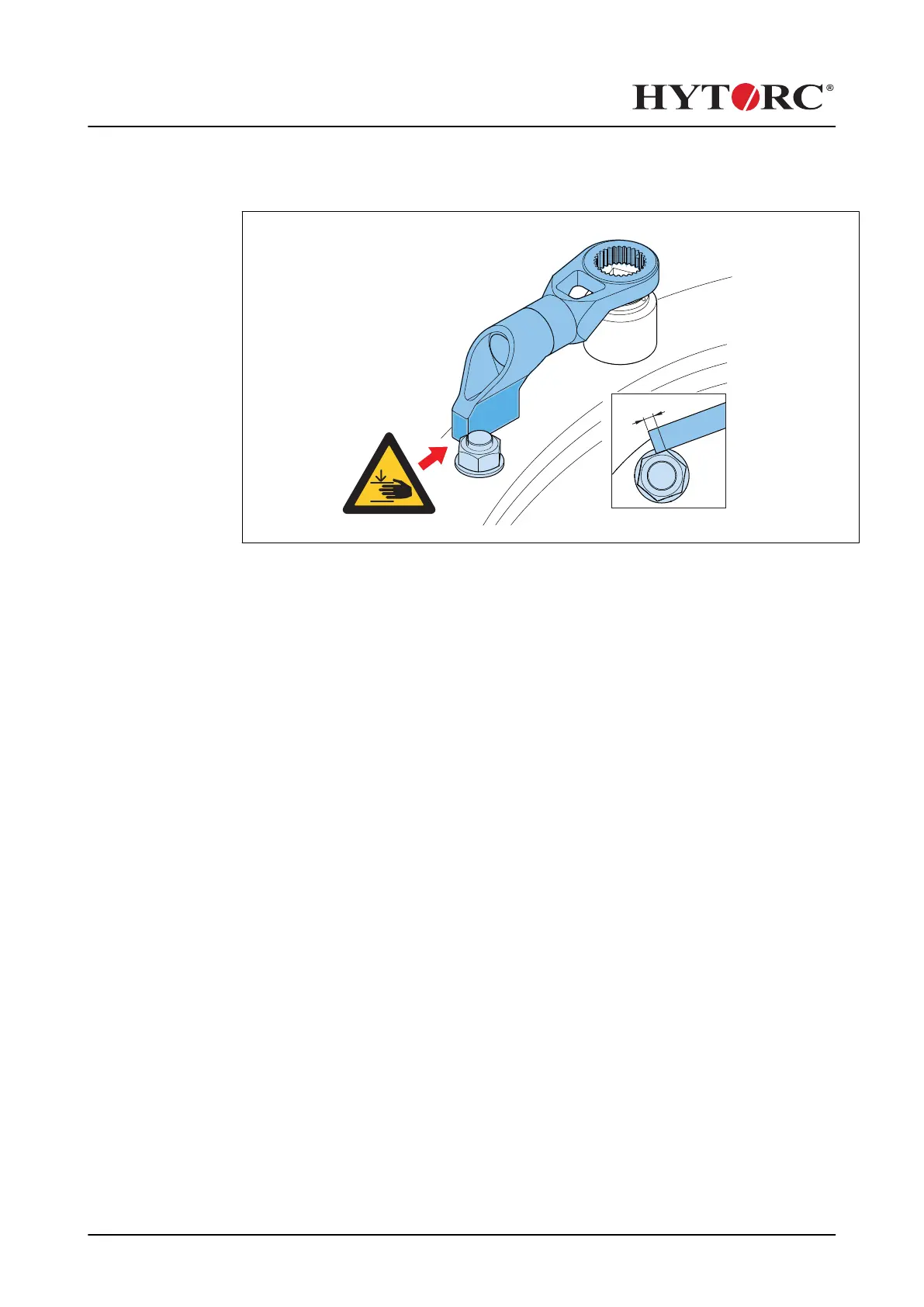

• Make sure that the end of the reaction arm has both horizontally and vertically at least

10 mm overlap with the reaction point. If a distance of at least 10 mm is not possible,

choose another reaction point or use an appropriate reaction arm.

• Make sure that the reaction arm is locked onto the spline of the tool.

• Avoid excessive play. Pressurize the system momentarily. If the tool tends to creep or

stand askew, stop immediately and adjust the reaction arm to a more solid and secure

position.

• Do not place the reaction arm against a round or inclined reaction point.

• Do not place any part of your body between the reaction arm and the reaction point.

• Do not place objects between the reaction arm and the reaction point.

• When you use a reaction cup, make sure that the reaction cup is placed over the

reaction point completely.

• When you use a reaction pin cup, make sure that the pin reaches the bottom of the

hex bolt.

2.2.4 Sockets

• Only use HYTORC sockets.

• Do not modify the sockets in any way.

• Do not use sockets that have been excessively heated or cooled.

• Use thick-walled heavy-duty sockets only. Do not use thin-walled sockets.

• Only use deep well sockets when strictly necessary. The excessive height causes

unnecessary bending forces.

• Do not use sockets that are used on impact wrenches. The impact deforms the drive

hole of the socket and hardens and brittles the steel. This can cause fracture of the

steel and increases the risk of flying objects.

• Make sure that the width across flats of the socket corresponds to the width across

flats of the nut or the bolt. Note the difference between metric and imperial

measurements.

• Place the tool with the socket on the nut or the bolt. Make sure that the socket is

placed over the nut or the bolt as far as possible.

• Make sure that the socket is secured to the tool.

• Do not use common extension pieces or step-up/step-down adapters. HYTORC can

develop customized accessories to ensure safe and simple operation. Contact your

local HYTORC representative for more information.

Safety

10 47 - 001 -

Loading...

Loading...