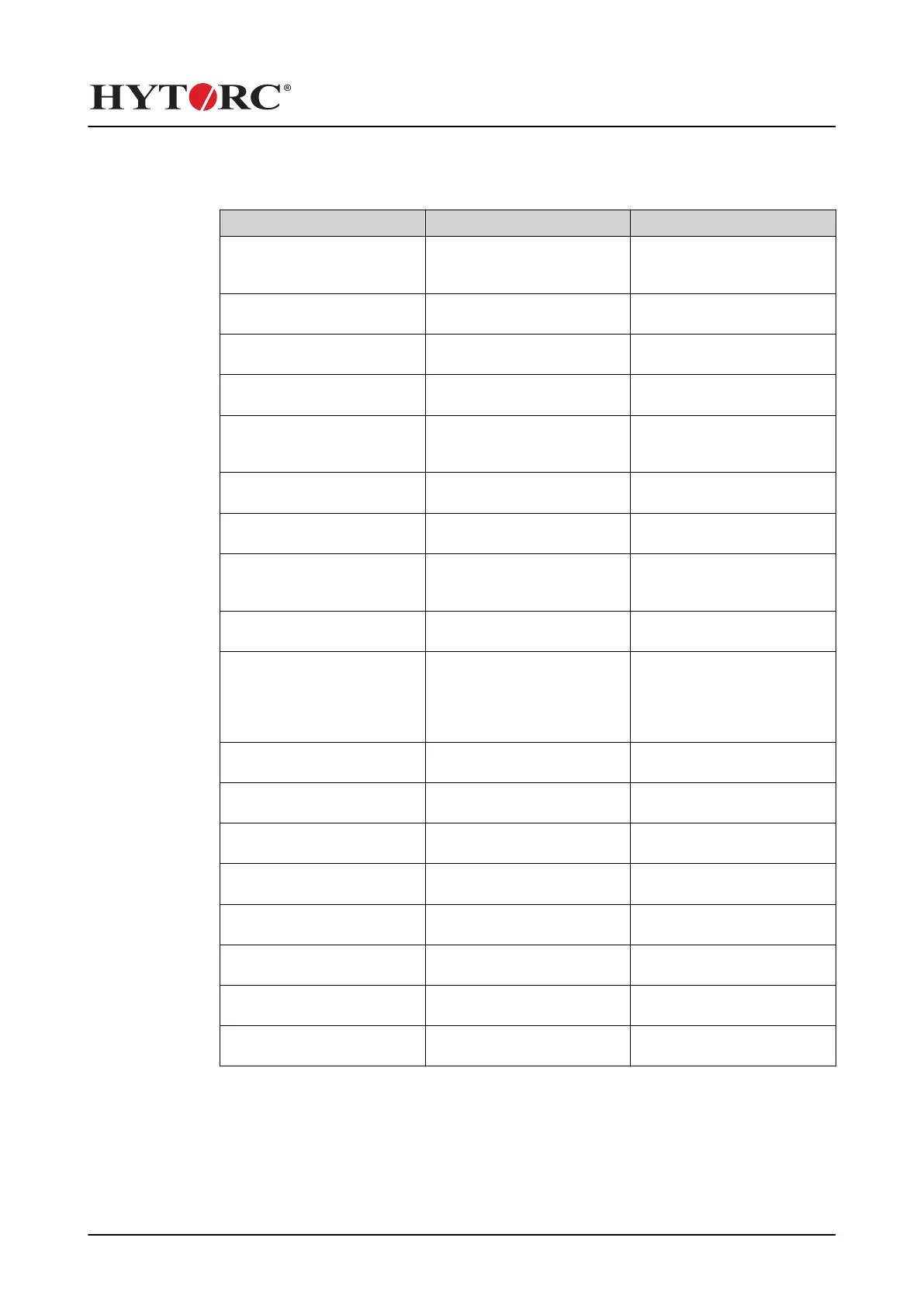

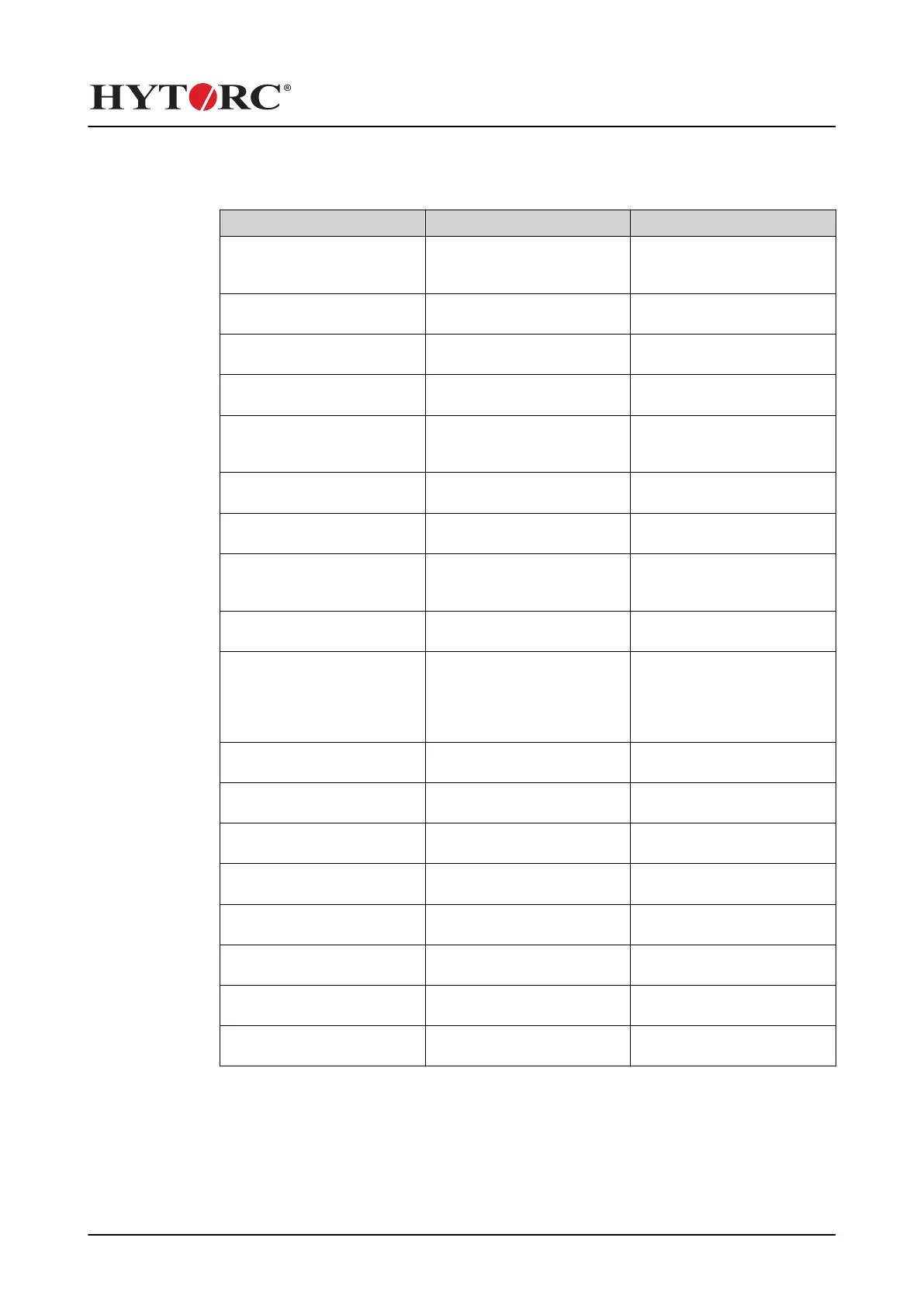

9 Troubleshooting

Problem Possible cause Solution

The tool does not move. The tool is not correctly lubrica-

ted.

Make sure that the air lubricator

is adjusted to four drops per

60-90 seconds.

The air supply is moist. Make sure that the air supply is

dry.

The air motor is defective. Contact your local HYTORC

representative.

The gearbox is defective. Contact your local HYTORC

representative.

The tool leaks externally. There is too much lubrication

oil in the tool.

Make sure that the air lubricator

is adjusted to four drops per

60-90 seconds.

The tool moves slower than

usual.

Air leaks from the tool. Contact your local HYTORC

representative.

The air motor is worn. Contact your local HYTORC

representative.

The tool is not correctly lubrica-

ted.

Make sure that the air lubricator

is adjusted to four drops per

60-90 seconds.

Gearbox maintenance is nec-

essary.

Contact your local HYTORC

representative.

The air pressure is too low. Make sure that the air supply

pressure is between 6.2 bar (90

psi) and 10 bar (145 psi) at a

maximum air consumption of

1,500 l/min.

The diameter of the air hose is

smaller than 3/4".

Use an air hose with an internal

diameter larger than 3/4".

The FRL filter is clogged. Contact your local HYTORC

representative.

The low-noise muffler is clog-

ged.

Contact your local HYTORC

representative.

The tool is out of calibration. Contact your local HYTORC

representative.

The tool moves while the trig-

ger switch is not pulled.

The control valve is dirty. Contact your local HYTORC

representative.

The control valve is worn. Contact your local HYTORC

representative.

The trigger switch does not

move.

The trigger switch is dirty. Contact your local HYTORC

representative.

The screws of the gearbox

housing are loose.

The screws are not correctly

tightened.

Tighten the screws correctly.

Troubleshooting

47 - 001 - 39

Loading...

Loading...