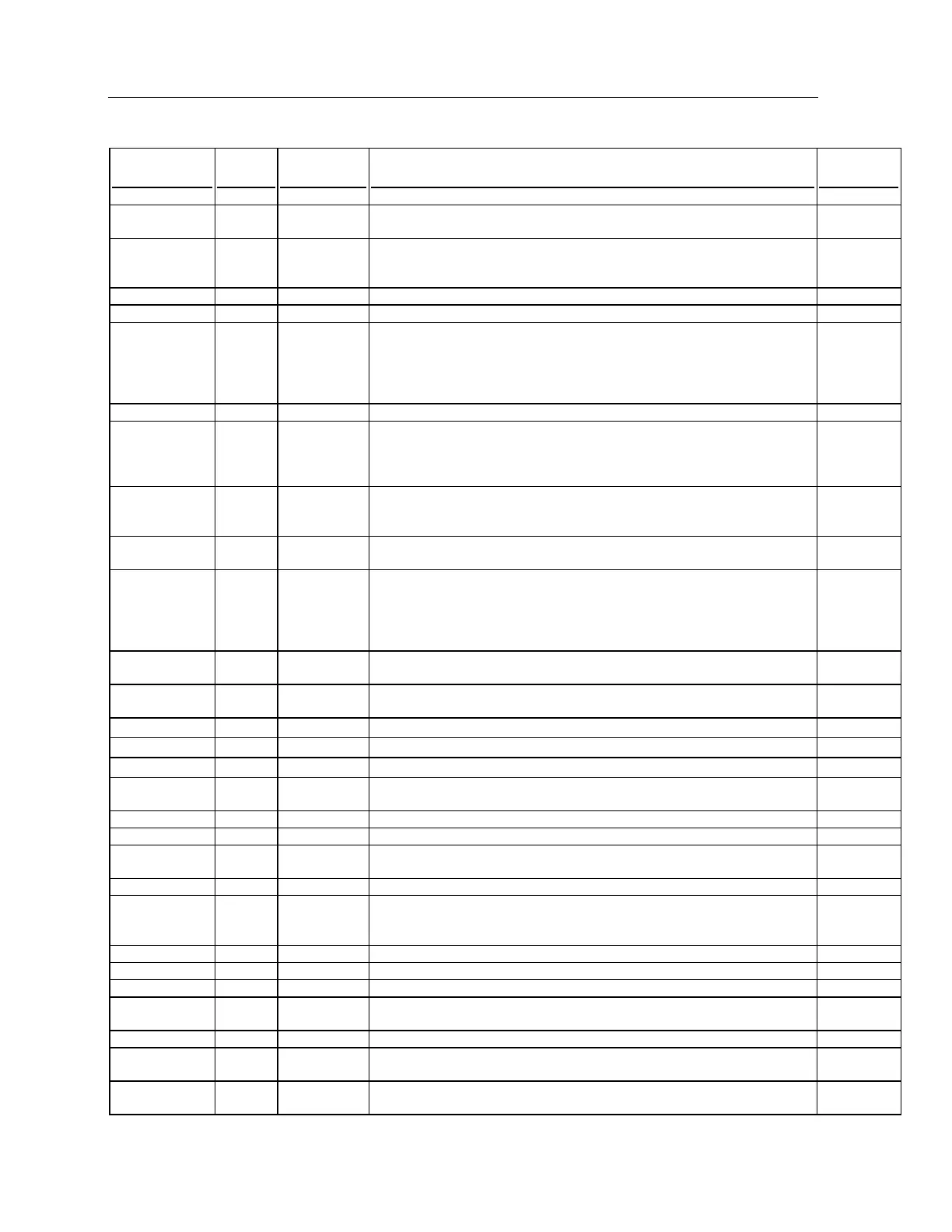

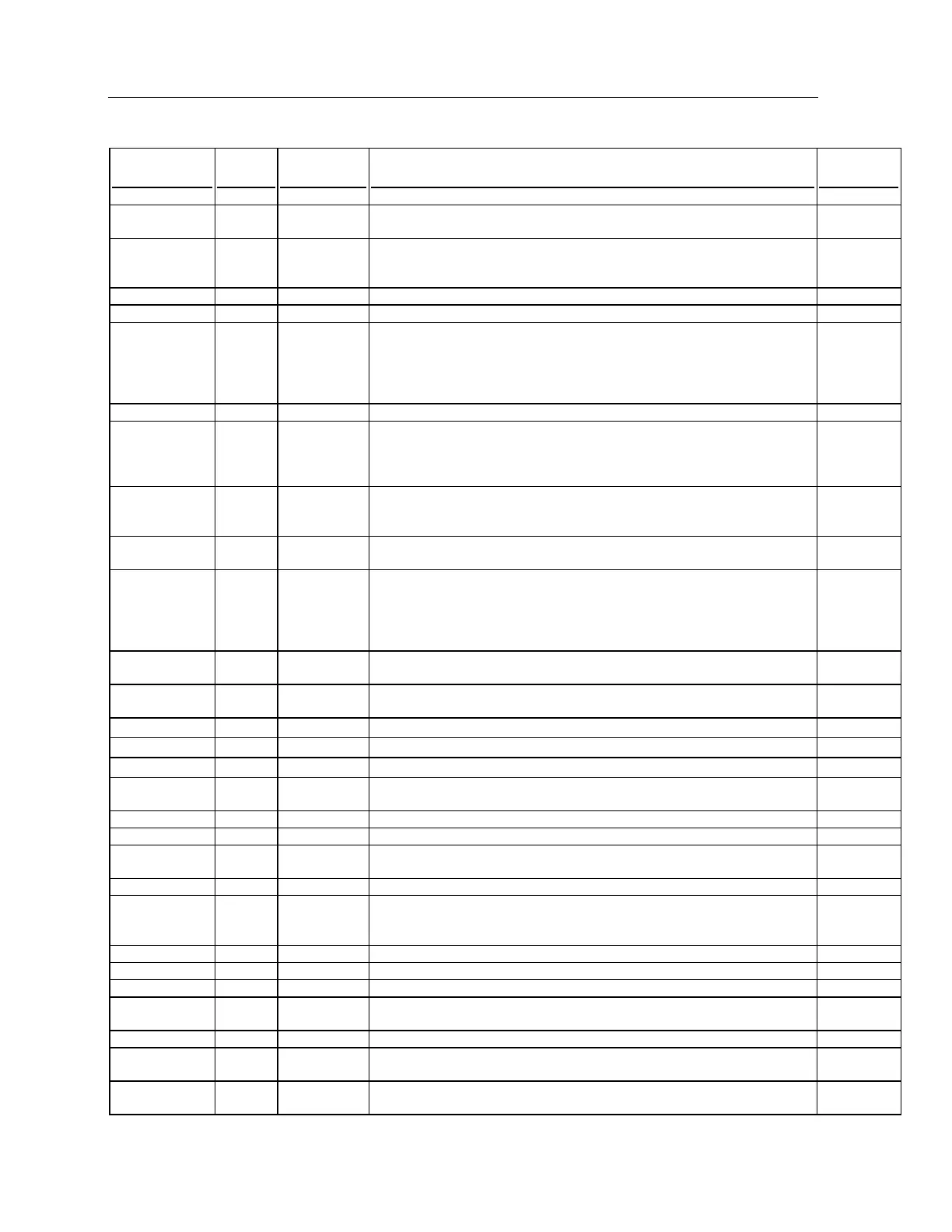

Chapter 5 General Reference 107

FREQUENCY ITEM KEY INSPECTION DESCRIPTION STATUS

Overall observation of crane for damaged or missing parts, cracked

welds, and presence of safety covers.

During operation, observe crane for abnormal performance, unusual

wear (loose pins, wire rope damage, etc.). If observed, discontinue

use and determine cause and severity of hazard.

Operate remote control devices to check for proper operation.

Operate all lights, alarms, etc. to check for proper operation.

Block or

Two-Block

Damage

Operate anti two-block or two-block damage prevention device to

check for proper operation.

Check tires (when in use) for proper inflation and condition.

Conditions

Check ground conditions around the equipment for proper support,

watching for ground settling under and around stabilizers and

supporting foundations, ground water accumulation, or similar

Check the equipment for level position within the tolerances specified

by the equipment manufacturer’s recommendations, both before each

shift and after each move and setup.

Check windows for cracks, breaks, or other deficiencies which would

hamper the operator's view.

stops, rail

clamps and

supporting

Check rails, rail stops, rail clamps and supporting surfaces when the

equipment has rail traveling.

Check safety devices and operational aids for proper operation.

Check electrical apparatus for malfunctioning, signs of apparent

excessive deterioration, dirt or moisture accumulation.

All daily inspection items.

Visual inspection of cylinders for leakage at rod, fittings, and welds.

Damage to rod and case.

Holding valves for proper operation.

Control valves for leaks at fittings and between stations.

Control valve linkages for wear, smoothness of operation, and

tightness of fasteners. Relief valve for proper pressure settings.

Bent, broken, or significantly rusted/corroded parts.

Electrical apparatus for malfunctioning, signs of apparent excessive

deterioration, dirt or moisture accumulation. Electrical systems for

presence of dirt, moisture, and frayed wires.

All structural members for damage.

All welds for breaks and cracks.

All pins for proper installation and condition.

All bolts, fasteners and retaining rings for tightness, wear and

corrosion.

Hydraulic pumps and motors for leakage at fittings, seals, and

between sections. Check tightness of mounting bolts.

Transmission/PTO for leakage, abnormal vibration & noise, alignment,

and mounting bolt torque.

Loading...

Loading...