Commissioning and Trial Run

‑54‑

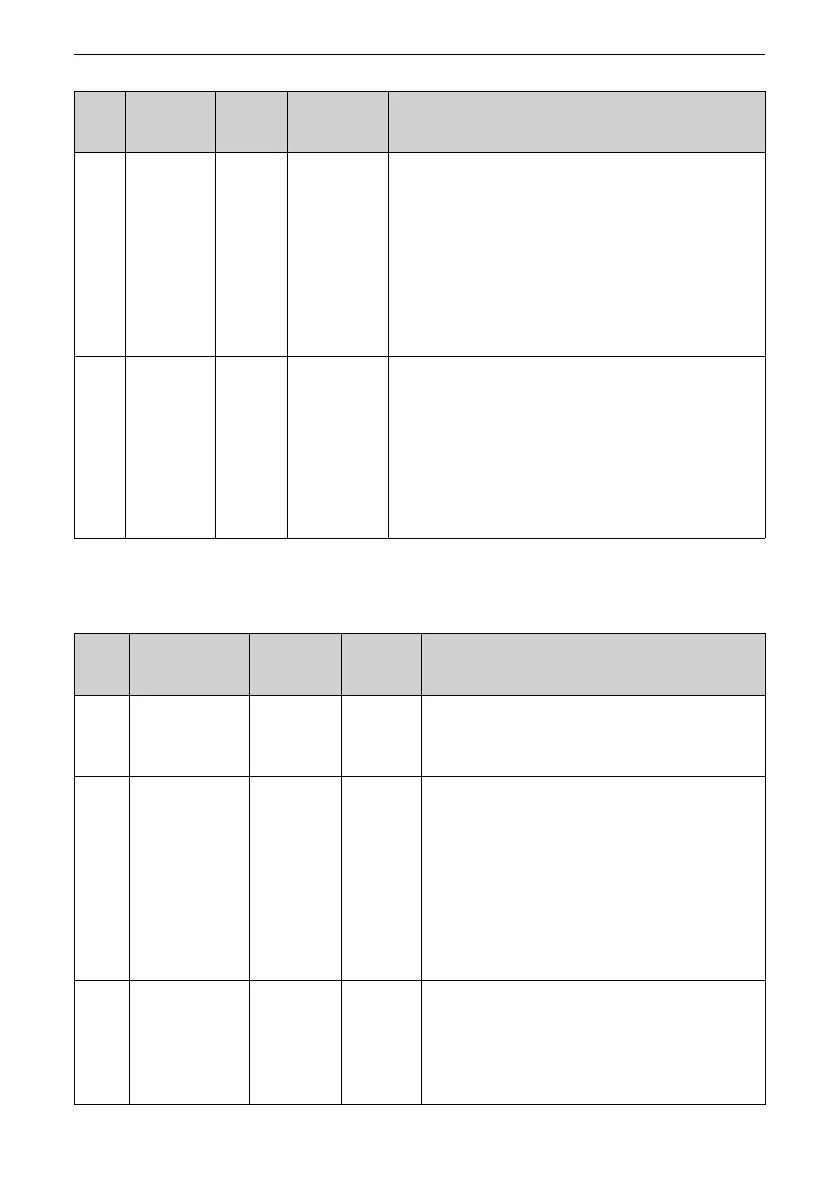

Param

eter

Code

Parameter

Name

Value

Range

Default Parameter Code

F2‑05 Switchover

frequency 2

F2‑02 to

F0‑10

10.00 Hz The speed loop PI parameters are divided into low‑speed and

high‑speed groups. If the running frequency is lower than F2‑02

(switching frequency 1), the speed loop PI adjustment parameters

are F2‑00 and F2‑01. If the running frequency is higher than F2‑05

(switching frequency 2), the speed loop PI adjustment parameters

are F2‑03 and F2‑04. If the running frequency falls between

switching frequency 1 and switching frequency 2, speed loop PI

adjustment parameters are switched between F2‑00/F2‑01 and

F2‑03/F2‑04. The parameter value must be larger than F2‑02

(switching frequency 1).

F2‑06 Vector

control slip

gain

50% to

200%

100% In the SVC mode, this parameter is used to adjust the speed

stability accuracy of the motor. For example, when the running

frequency of the motor is lower than the output frequency of the

AC drive, you can increase the value of this parameter. In the FVC

mode, this parameter is used to adjust the output current of the

AC drive with the same load. For example, if the load capacity of a

high‑power AC drive is weak, decrease the value of this parameter

gradually. No adjustment is required under normal

circumstances.

2.2.12(Optional) FVC Parameter Settings

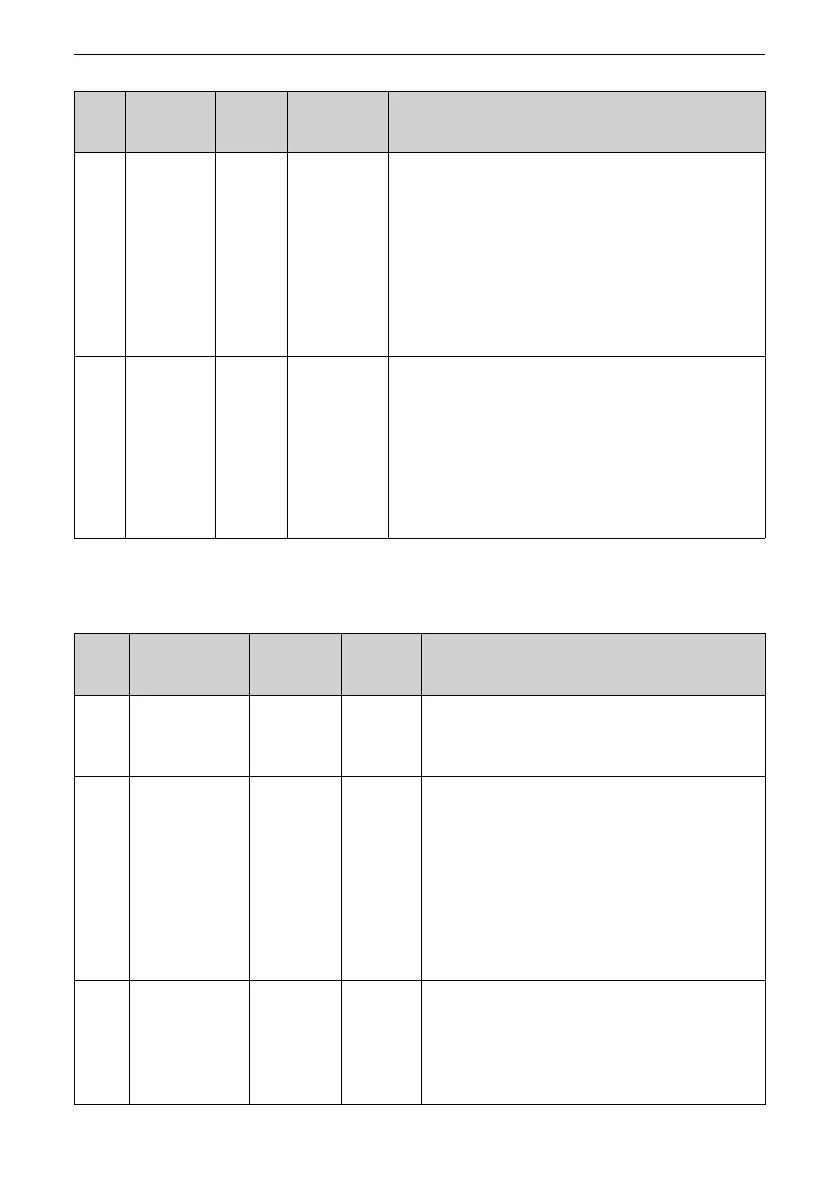

Parame

ter

Code

Parameter Name Value Range Default Parameter Code

F1‑27 Encoder PPR 1–65535 1024 This parameter defines the number of pulses generated per

revolution of the encoder disk. In the feedback vector

control (FVC) mode, set this parameter properly; otherwise,

the motor will malfunction.

F1‑28 Encoder type 0: ABZ

incremental

encoder

1: 23‑bit

encoder

2: Resolver

3: External

input

4: Sin‑cos

encoder

0 Encoders are classified into incremental encoders and

absolute encoders.

● An incremental encoder converts displacement into

periodic electrical signals, which are then converted into

pulses that are counted. That is, the magnitude of

displacement is expressed as the number of pulses.

● An absolute encoder maps each position to a digital code.

Therefore, its indication is related only to the start and

end positions of the measurement, but is not related to

any intermediate process of measurement.

F1‑34 Number of resolver

pole pairs

1–65535 1 A resolver is an electromagnetic transducer, also known as

a synchronous resolver. It is a small AC motor used to

measure angles, including angular displacement and

angular velocity of shafts. It consists of stators and rotors.

This parameter defines the number of pole pairs of a

resolver. More pole pairs indicate higher accuracy.

Loading...

Loading...