6 | Fieldbus Guide | Version 1.02 www.invertekdrives.com

3

Parameter Configuration for Fieldbus Operation

3. Parameter Configuration for Fieldbus Operation

3.1. Overview

The following parameters are used to configure any fieldbus connection. Refer to the Programming Guide for further information.

Parameters are explained more fully in the Programming Guide.

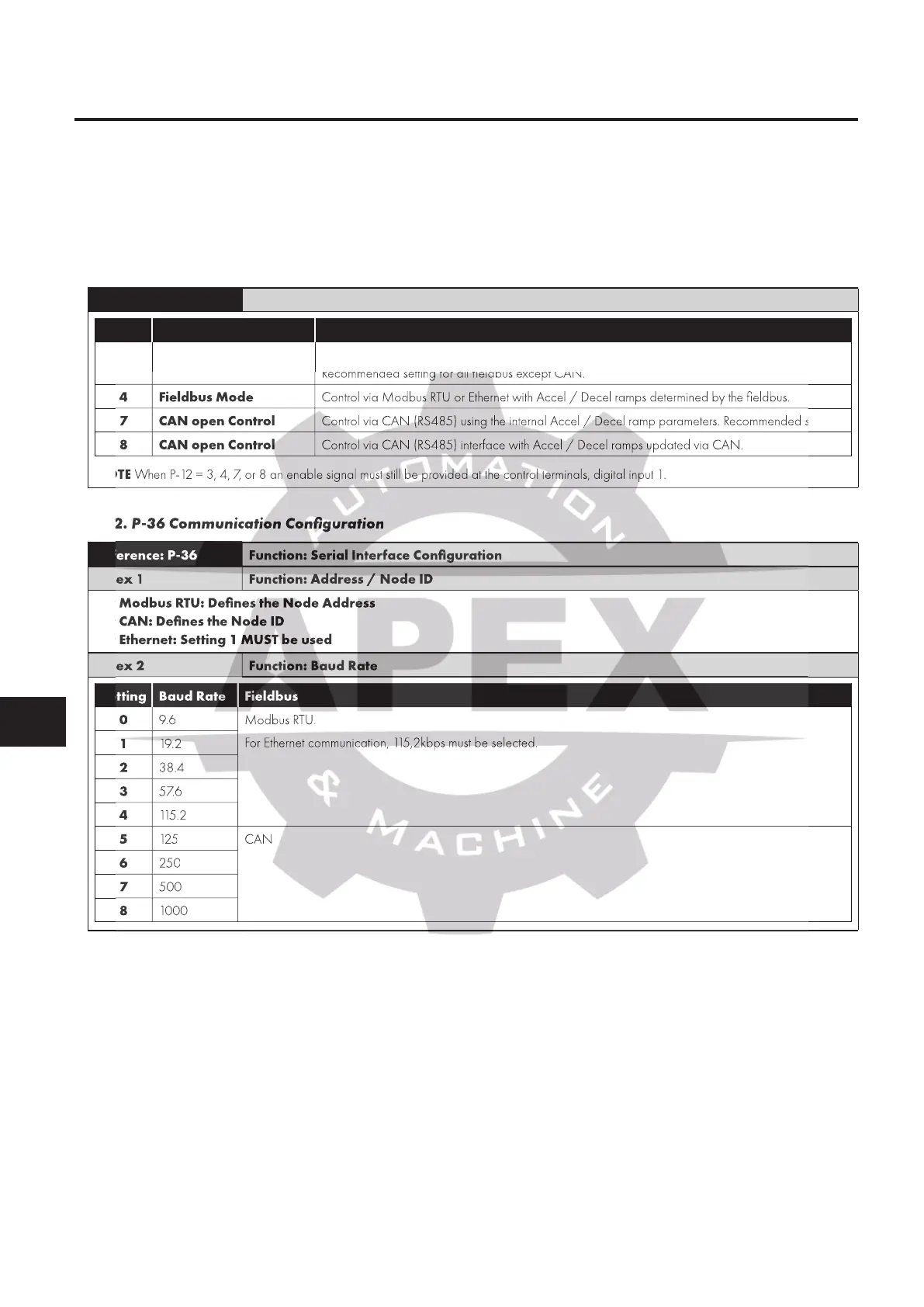

3.1.1. Parameter P-12: Control Source

The fieldbus interfaces may be used to monitor information from the drive regardless of where the control commands originate.

If it is required to control the drive through the fieldbus interface, the following parameter should be adjusted as shown.

Reference: P-12 Function: Control Source Selection

Setting Function Description

3 Fieldbus Mode

Control via Modbus RTU or Ethernet using the internal Accel / Decel ramp parameters.

Recommended setting for all fieldbus except CAN.

4 Fieldbus Mode Control via Modbus RTU or Ethernet with Accel / Decel ramps determined by the fieldbus.

7 CAN open Control Control via CAN (RS485) using the internal Accel / Decel ramp parameters. Recommended setting.

8 CAN open Control Control via CAN (RS485) interface with Accel / Decel ramps updated via CAN.

NOTE When P-12 = 3, 4, 7, or 8 an enable signal must still be provided at the control terminals, digital input 1.

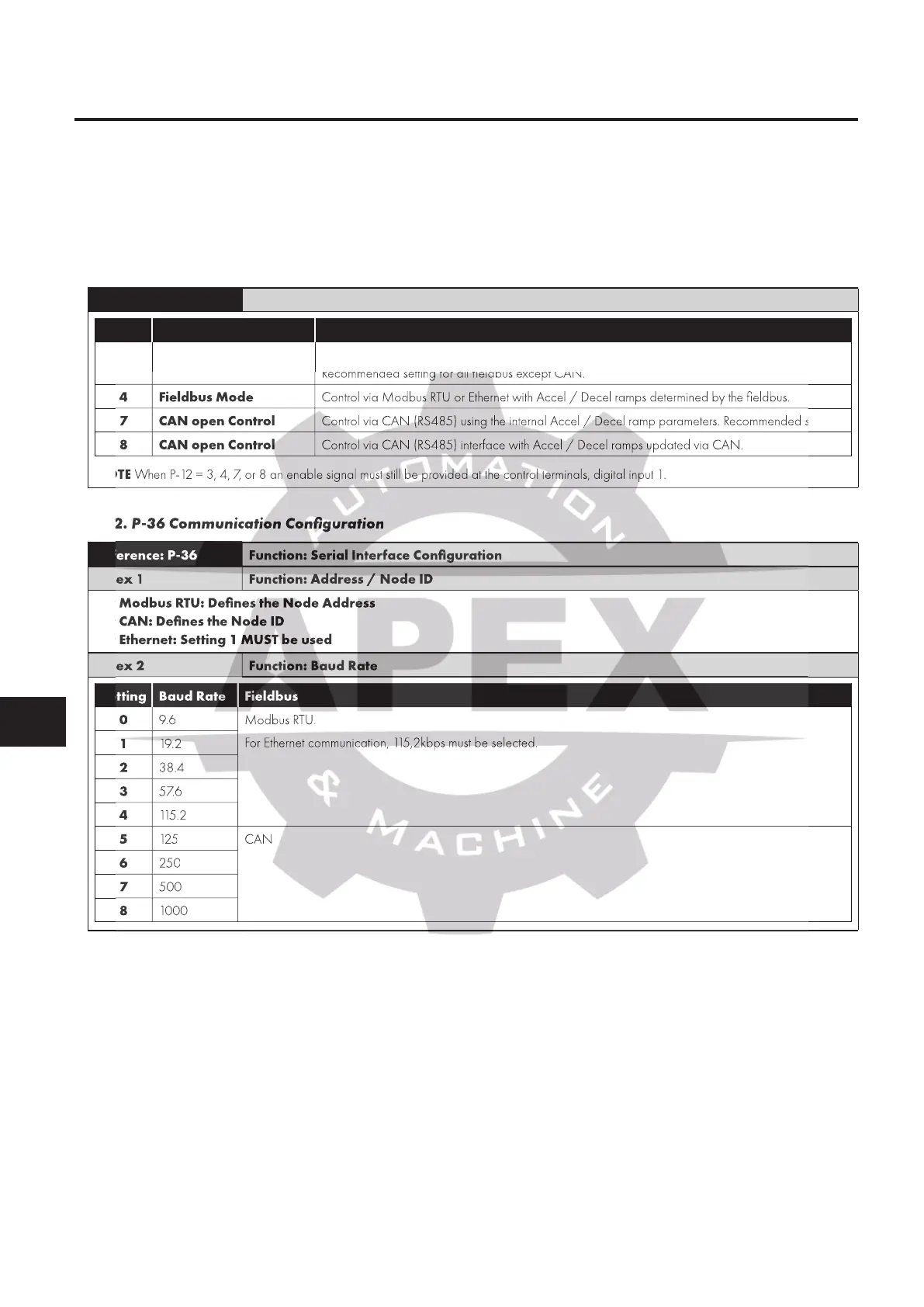

3.1.2. P-36 Communication Configuration

Reference: P-36 Function: Serial Interface Configuration

Index 1 Function: Address / Node ID

For Modbus RTU: Defines the Node Address

For CAN: Defines the Node ID

For Ethernet: Setting 1 MUST be used

Index 2 Function: Baud Rate

Setting Baud Rate Fieldbus

0 9.6 Modbus RTU.

For Ethernet communication, 115,2kbps must be selected.

1 19. 2

2 38.4

3 57.6

4 115 . 2

5 125 CAN

6 250

7 500

8 1000

Recommended setting for all fieldbus except CAN.

Control via Modbus RTU or Ethernet with Accel / Decel ramps determined by the fieldbus.

Control via CAN (RS485) using the internal Accel / Decel ramp parameters. Recommended setting.

Control via CAN (RS485) interface with Accel / Decel ramps updated via CAN.

When P-12 = 3, 4, 7, or 8 an enable signal must still be provided at the control terminals, digital input 1.

3.1.2. P-36 Communication Configuration

Function: Serial Interface Configuration

Function: Address / Node ID

For Modbus RTU: Defines the Node Address

For CAN: Defines the Node ID

For Ethernet: Setting 1 MUST be used

Setting Baud Rate Fieldbus

Setting Baud Rate Fieldbus

Setting Baud Rate Fieldbus

For Ethernet communication, 115,2kbps must be selected.

Loading...

Loading...