DA180 series basic AC servo drive Commissioning

-234-

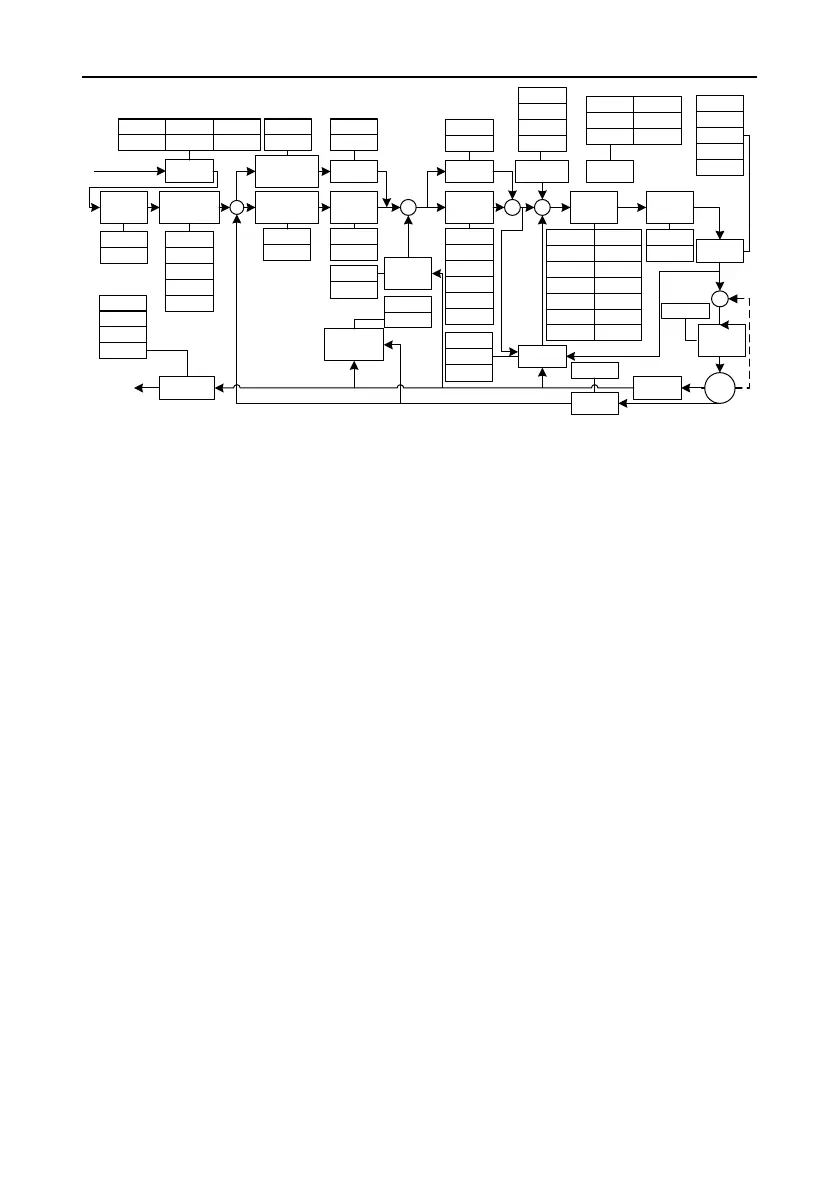

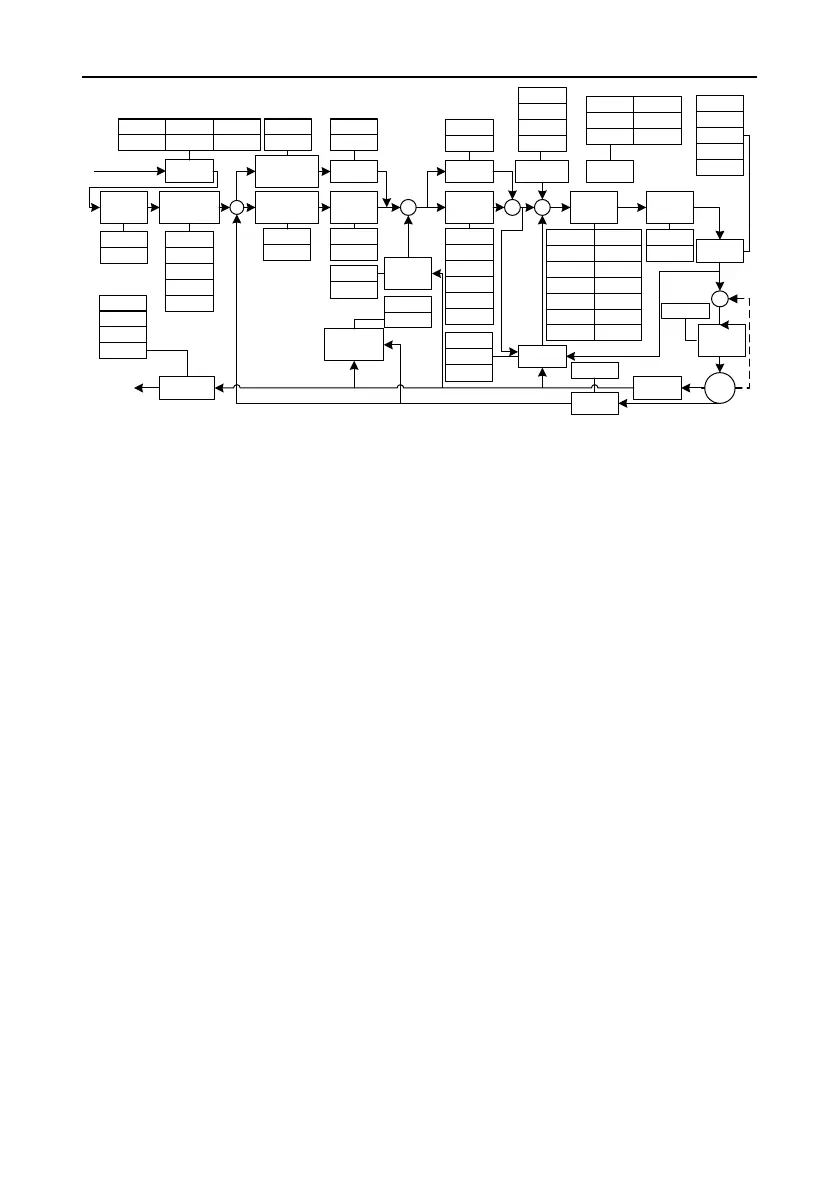

P2.10

P2.11

P2.02

P2.07

P1.29

P1.30

P2.04

P1.31

P1.32

P2.03

P2.00

P2.01

P1.33

P1.34

P2.09

P2.08

P2.12

P2.13

P0.06

P0.07

P0.08

P2.42

P2.43

P1.23

P1.24

P1.25

P1.26

P1.27

P1.28

P1.19 P1.20

P2.20

P2.22

P2.71

P2.72

P2.73

P2.24

P2.25

P2.23 P2.26

P0.09

P0.10

P0.11

P4.53

P4.51

P4.52

P4.67

P4.60

P4.61

P4.62

Position command

P0.27

P0.28

P0.29

P0.33

P0.34

P1.35

P1.36

P0.25

P0.26P0.22

P1.37

P1.38

P1.39

P2.70

P2.41

Electronic

gear

Speed

feedforward

Torque

feedforward

Friction

compensation

Gain

switching

Position

command

vibration control

Position

smoothing

filter

Position

controller

Torque filterNotch filter

Speed

controller

Torque limit

Frequency-

division output

Encoder

Motor

Grating ruler

Disturbance

control

Current

controller

Speed

detection

filter

Hybrid-control

deviation

calculation

P1.02

P1.01

P2.06

P2.05

Frequency-

division ratio of

grating ruler

P4.60

P4.61

Frequency-

division ratio of

grating ruler

P4.60

P4.61

The common procedure for adjusting parameters in position mode is as follows:

1. Restore default settings.

For details, see section 5.2.5.3 "Factory parameter restoring".

2. Adjust the position loop gain.

If the servo motor runs with default settings but the system vibrates with buzzes, decrease the

position loop gain (that is, P2.02 or P2.07) or increase it when the system rigidity is low.

3. Adjust the position smoothing filter.

In position control, if the input frequency changes of position pulse commands are noticeable, huge

surges may be caused. You need to adjust the P0.33 [Position command smooth filter time] or P0.34

[Position command FIR filter time].

4. Adjust the electronic gear.

If the pulse generation device is limited on the pulse sending frequency or the sending frequency

does not meet mechanical requirements, you can change the pulse input frequency by adjusting

P0.22 [Pulses per motor resolution] or electronic gear ratio parameters P0.25, P0.26, P0.27, P0.28,

and P0.29, so as to meet position control requirements.

5. Adjust the position feed-forward.

If the residual pulses are great or no-deviation tracking is required, you can adjust the speed

feed-forward gain parameter P2.10 and speed feed-forward filtering parameter P2.11 to improve

position tracking performance. However, if the speed feed-forward gain is too large, the system may

vibrate.

6. Set the frequency division for feedback pulse output.

If feedback pulses need to be output, you can set the frequency-division output coefficient parameters

P0.06 and P0.07 to change the pulse output frequency.

Loading...

Loading...