Goodrive35 Series Closed-loop Vector Control VFD Basic operation instruction

144

Suggestions:

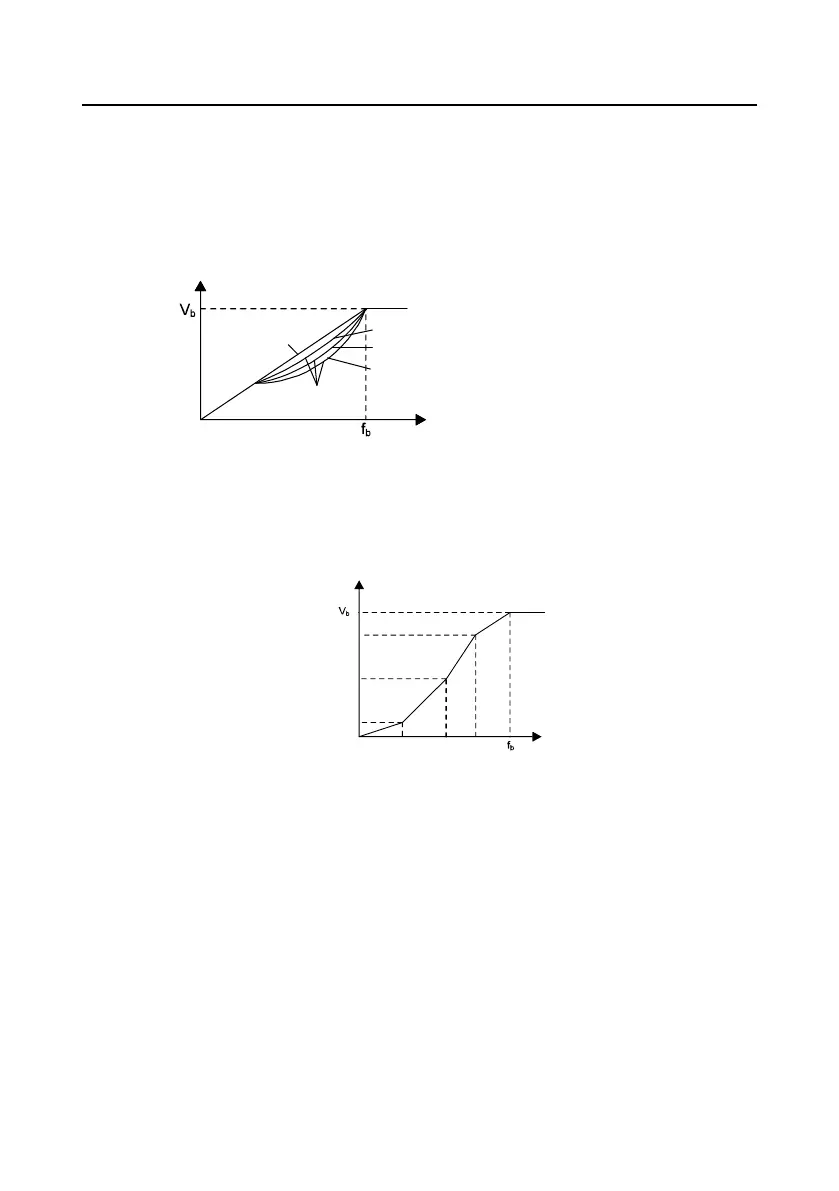

1. For the load of constant torque, such as the conveyor belt which runs linearly. It is properly to select

linear V/F curve because it needs constant torque.

2. For the load of decreasing torque, such as fans and water pumps, it is properly to select

corresponding 1.3th, 1.7th or 2th power of V/F curve because the actual torque is 2-squared or

3-squared of the rotating speed.

Output voltage

Output frequency

Linear type

Square type

Torque step-down V/F curve (1.3 order)

Torque step-down V/F curve (1.7 order)

Torque step-down V/F curve (2.0 order)

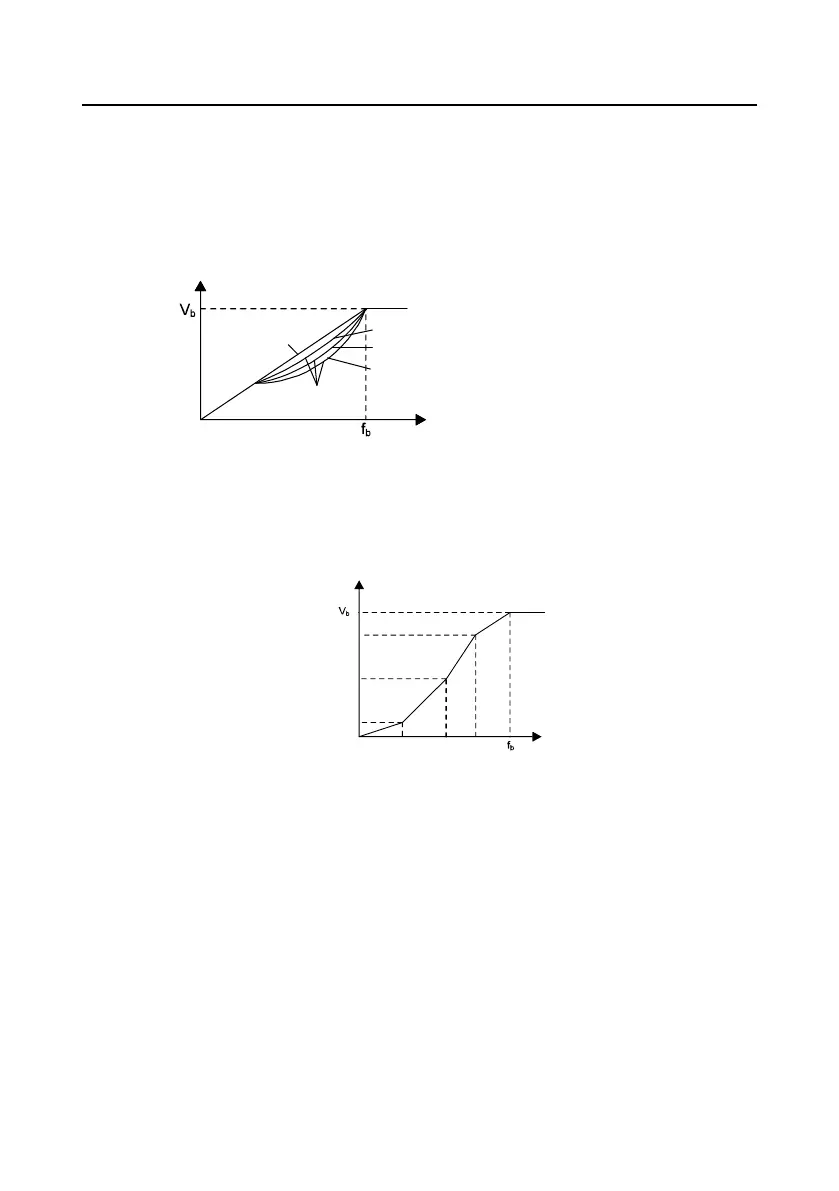

Goodrive35 series VFDs provide multi-dots V/F curve, the user can change the output V/F curve by

setting the voltage and frequency of three middle dots. The whole curve is consisted of 5 dots. The

starting dot is (0 Hz, 0 V), and the ending dot is (the basic frequency of the motor, the rated voltage

of the motor). During the setting processing: 0≤f

1

≤f

2

≤f

3

≤the basic frequency of the motor; 0≤ V

1

≤ V

2

≤

V

3

≤the rated voltage of the motor.

Output voltage

Output

frequency

(Hz)

V1

V2

V3

f1 f2 f3

100.0%

Goodrive35 series VFDs provide special function code for SVPWM control mode which can improve

the performance of SVPWM control by means of setting.

1. Torque boost

Torque boost function can effectively compensate for the performance of low speed torque during

SVPWM control. Automatic torque boost has been set by default to enable the VFD to adjust the

torque boost value based on the actual load conditions.

Note:

The torque boost takes effect only when the frequency is under the cap frequency of the boost. If the

torque boost is too big, low frequency vibration or overcurrent fault may occur to the motor. If such

situation occurs, lower the torque boost value..

Loading...

Loading...