Goodrive35 Series Closed-loop Vector Control VFD Basic operation instruction

194

be adjusted. If the pulse train is selected to control the speed, set P21.00=0000, P00.06 or

P00.07=12, AB pulse train, then the acceleration and deceleration time depend on the time of the

VFD and the parameter setting is determined by P21. In speed control mode, set the filter time of AB

pulse by P21.29.

(8)The input frequency of the pulse train is the same as the feedback frequency of the encoder pulse.

The relationship between them can be changed by modifying P21.11 and P21.12.

(9)When run command or servo enable is valid by setting P21.00 or terminal function 63, the VFD will

run into the pulse string servo mode.

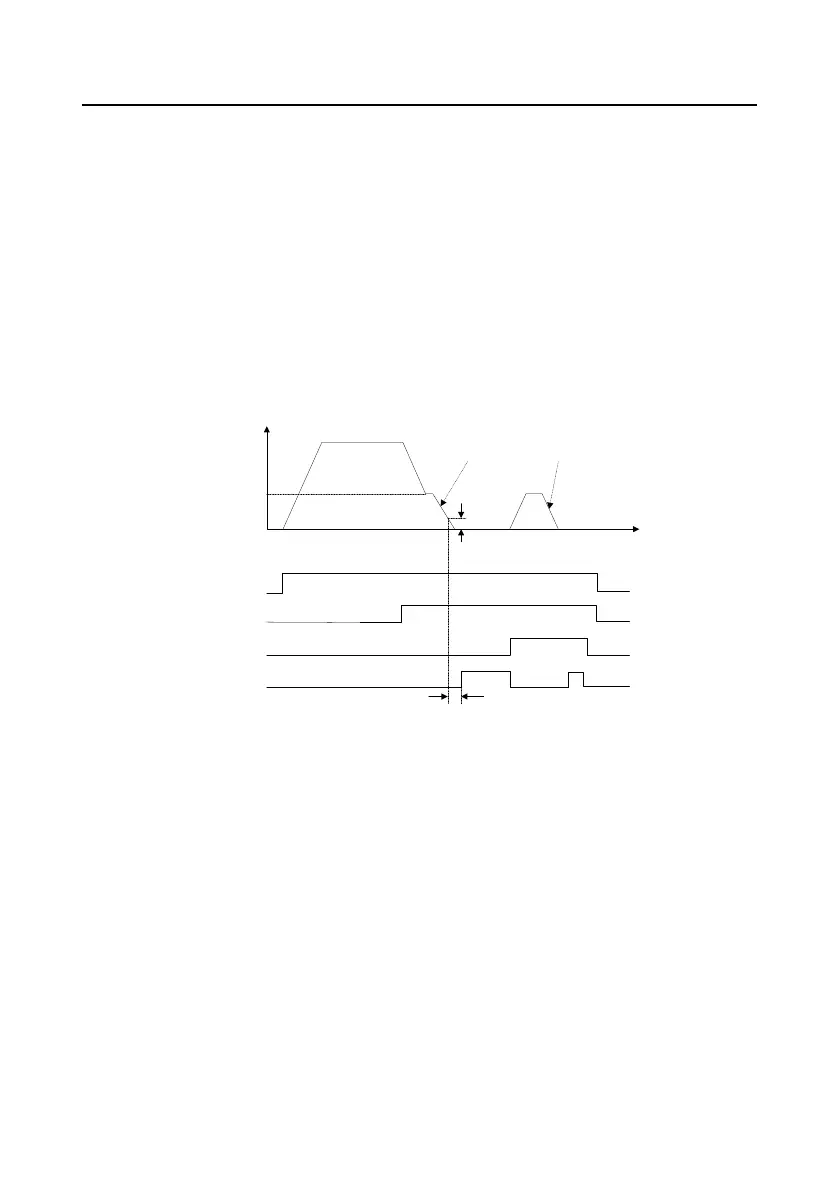

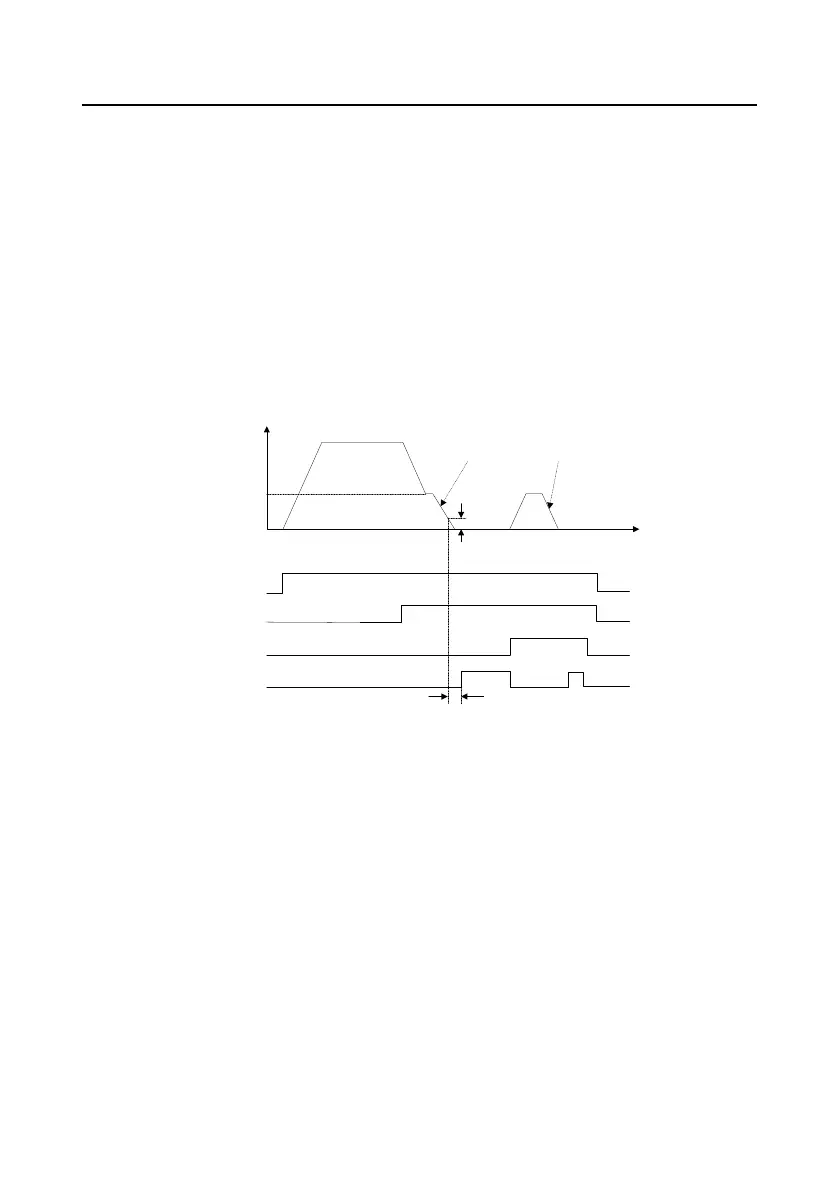

4. Debugging steps of spindle positioning

The spindle positioning is the function of stopping such as zeroing and scaling on the basis of

closed-loop vector control.

Frequency

Time

Running

command

Return

command

Zeroing

terminal 1

P22.01

Position

finished signal

P21.10

P21.09

P22.02

ON

ON

ON

ON

ON

P21.25

P21.25

The steps of (1)–(4) are the same as the 4 steps in close-loop vector control mode. The function of

spindle positioning is available in the position control mode and speed control mode.

(5) Set P22.00.bit0=1 and P22.00.bit1. If the system applies encoder to detect the speed, set

P22.00.bit1=0, and if the system applies the photoelectric switch to detect the speed, set

P22.00.bit1=1; set P22.00.bit2, P22.00.bit3 and P22.00.bit7

(6)Spindle zeroing

a) Set P22.00.bit4 to select the positioning direction.

b) There are 4 zero positions in P22 group. Set P05 to select the zeroing position. Operation on

P18.10 can watch the stopping state.

c) The positioning length is determined by the deceleration time and the deceleration speed.

(7) Spindle scaling

There are 7 scale positions in P22 group. Set P05 to select the scale position. Enable corresponding

Loading...

Loading...