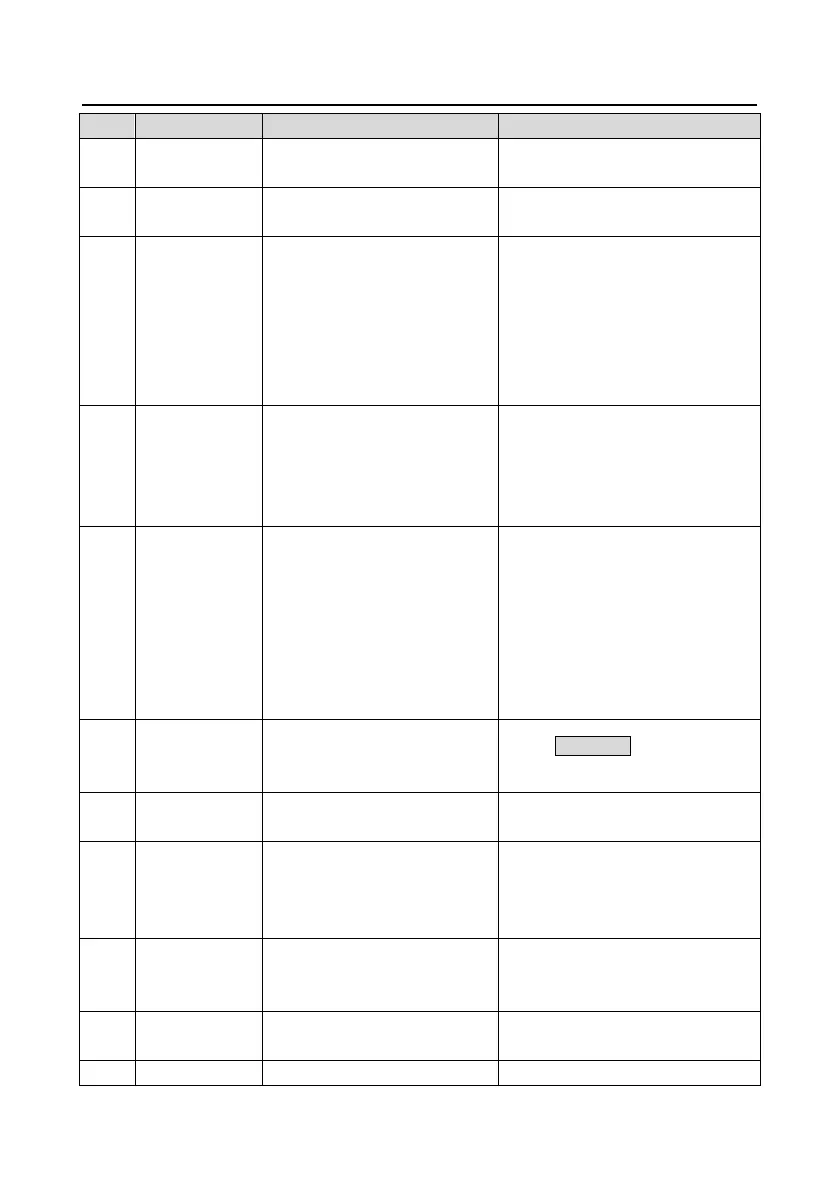

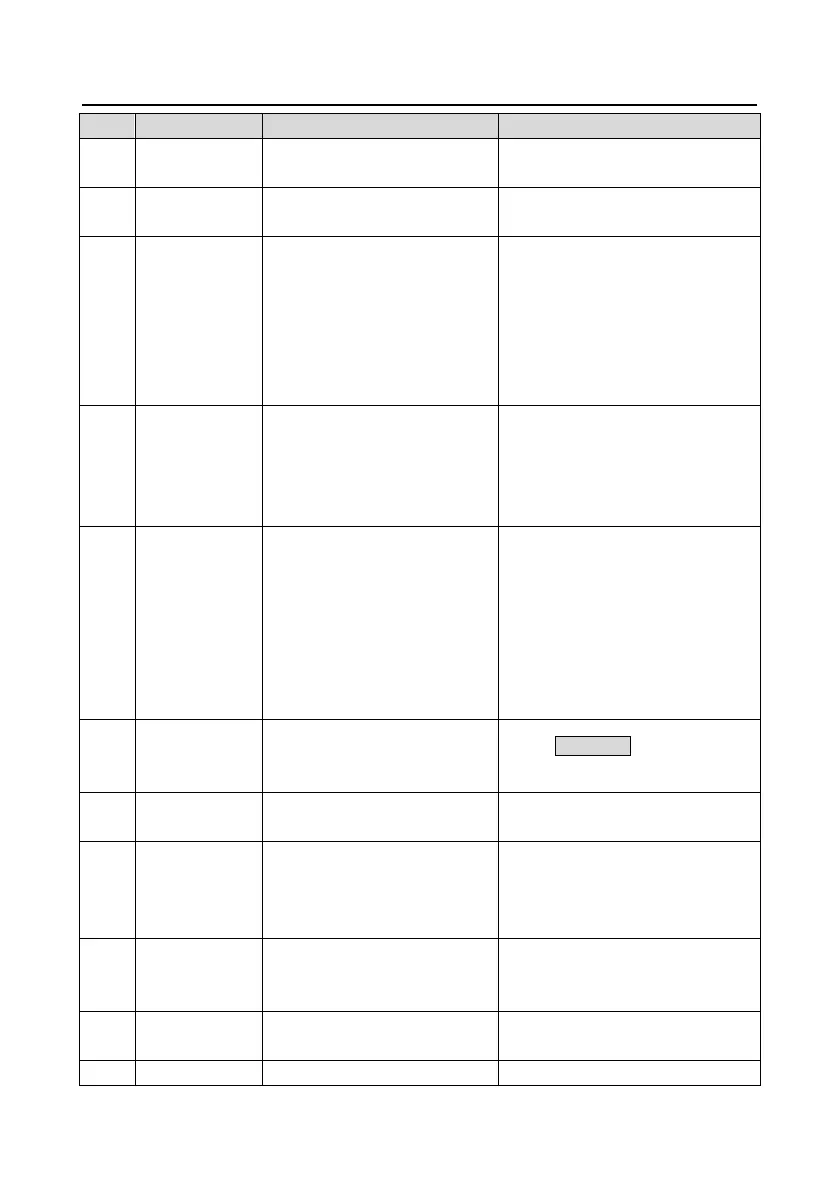

Goodrive35 Series Closed-loop Vector Control VFD Fault tracking

202

Inverter module

overheated

The time of overload running is

too long.

Lower the ambient temperature

SI external fault input terminals

act

Check the external device input

The baud rate setting is

incorrect.

Fault occurs to the

communication wiring.

Communication address is wrong.

There is strong interference to

the communication.

Set proper baud rate

Check the communication

connection distribution

Set proper communication address.

Chang or replace the connection

distribution or improve the

anti-interference capability.

The connection of the control

board is not good

Hall components is broken

The modifying circuit is

abnormal.

Check the connector and re-plug

Change the Hall

Change the main control panel

The motor capacity does not

comply with VFD capability

The rated parameter of the motor

does not set correctly.

The offset between the

parameters from autotune and

the standard parameter is huge

Autotune overtime

Change the VFD mode

Set the rated parameter according to

the motor name plate

Empty the motor load and re-identify

Check the motor connection and set

the parameter.

Check if the upper limit frequency is

above 2/3 of the rated frequency.

Error of controlling the write and

read of the parameters

Damage to EEPROM

Press STOP/RST to reset

Change the main control panel

PID feedback

outline fault

PID feedback offline

PID feedback source disappear

Check the PID feedback signal

Check the PID feedback source

Brake circuit fault or damage to

the brake pipes

External brake resistor is

insufficient

Check the brake unit and , change

new brake pipe

Increase the brake resistor

The actual running time of the

VFD is above the internal setting

running time.

Ask for the supplier and adjust the

setting running time.

VFD will report overload

pre-alarm based on the set value.

Check the load and the overload

pre-alarm threshold.

The connection of the keypad

Check the keypad wires and ensure

Loading...

Loading...