Goodrive35 Series Closed-loop Vector Control VFD Function parameters

68

Detailed instruction of parameters

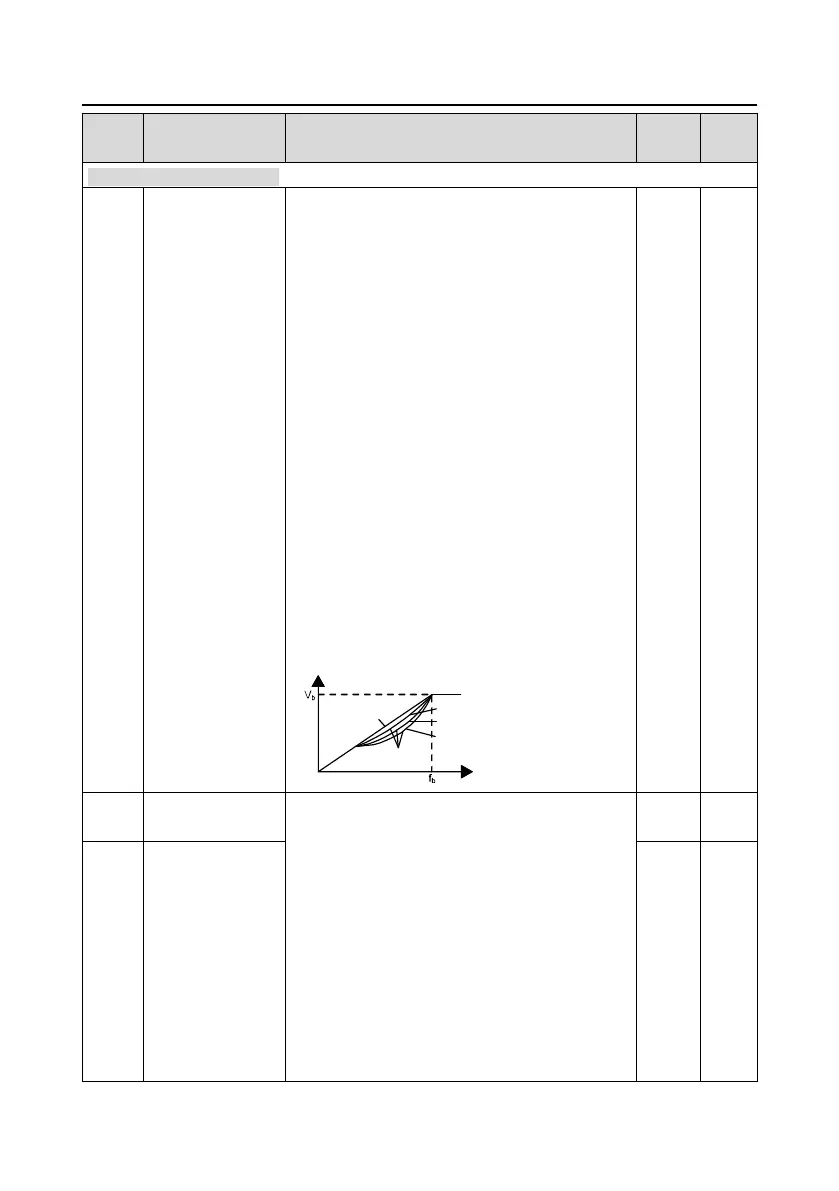

Motor 1 V/F curve

setting

These function codes define the V/F curve of

Goodrive35 motor 1 to meet the need of different

loads.

0: Straight line V/F curve; applying to the constant

torque load

1: Multi-dots V/F curve

2: 1.3

th

power low torque V/F curve

3: 1.7

th

power low torque V/F curve

4: 2.0

th

power low torque V/F curve

Curves 2–4 apply to the torque loads such as fans

and water pumps. Users can adjust according to the

features of the loads to achieve a best

energy-consuming effect.

5: Customized V/F (V/F separation); on this mode, V

and F can be separated from f and f can be adjusted

through the frequency given channel set by P00.06

or the voltage given channel set by P04.27 to

change the feature of the curve.

Note: V

b

in the below picture is the motor rated

voltage and f

b

is the motor rated frequency.

Output voltage

Output frequency

Linear type

Square type

Torque step-down V/F curve (1.3

th

order)

Torque step-down V/F curve (1.7

th

order)

Torque step-down V/F curve (2.0

nd

order)

Torque boost to the output voltage for the features of

low frequency torque. P04.01 is for the Max Output

voltage V

b

.

P04.02 defines the percentage of closing frequency

of manual torque to f

b

.

Torque boost should be selected according to the

load. The bigger the load is, the bigger the boost is.

Too big torque boost is inappropriate because the

motor will run with over-magnetic, and the current of

the VFD will increase to raise the temperature of the

VFD and decrease the efficiency.

When the torque boost is set to 0.0%, the VFD is

Torque boost close

of motor 1

Loading...

Loading...