SV-DA200 series AC servo drives Faults and solutions

‐91‐

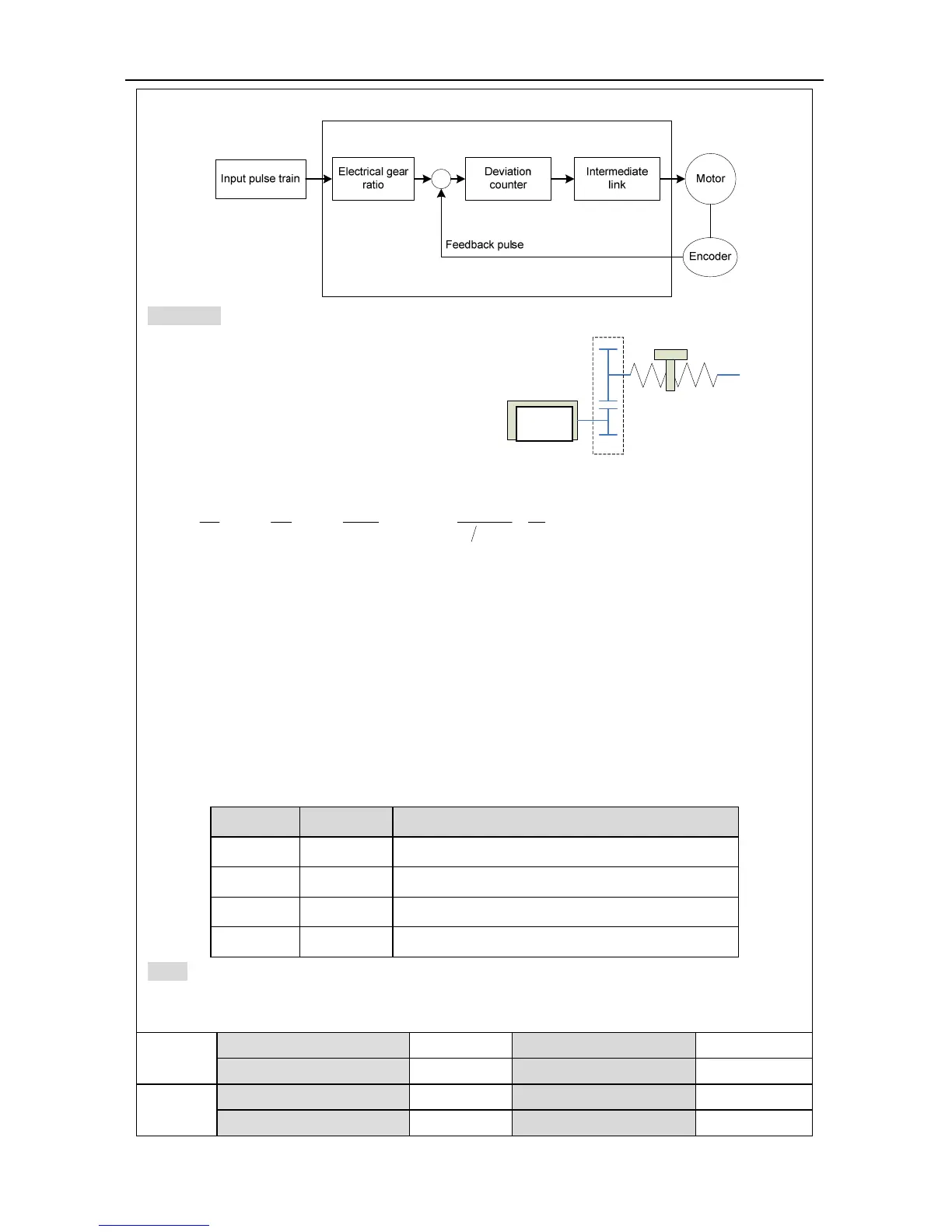

Below is the schematic diagram of the electronic gear ratio in the system:

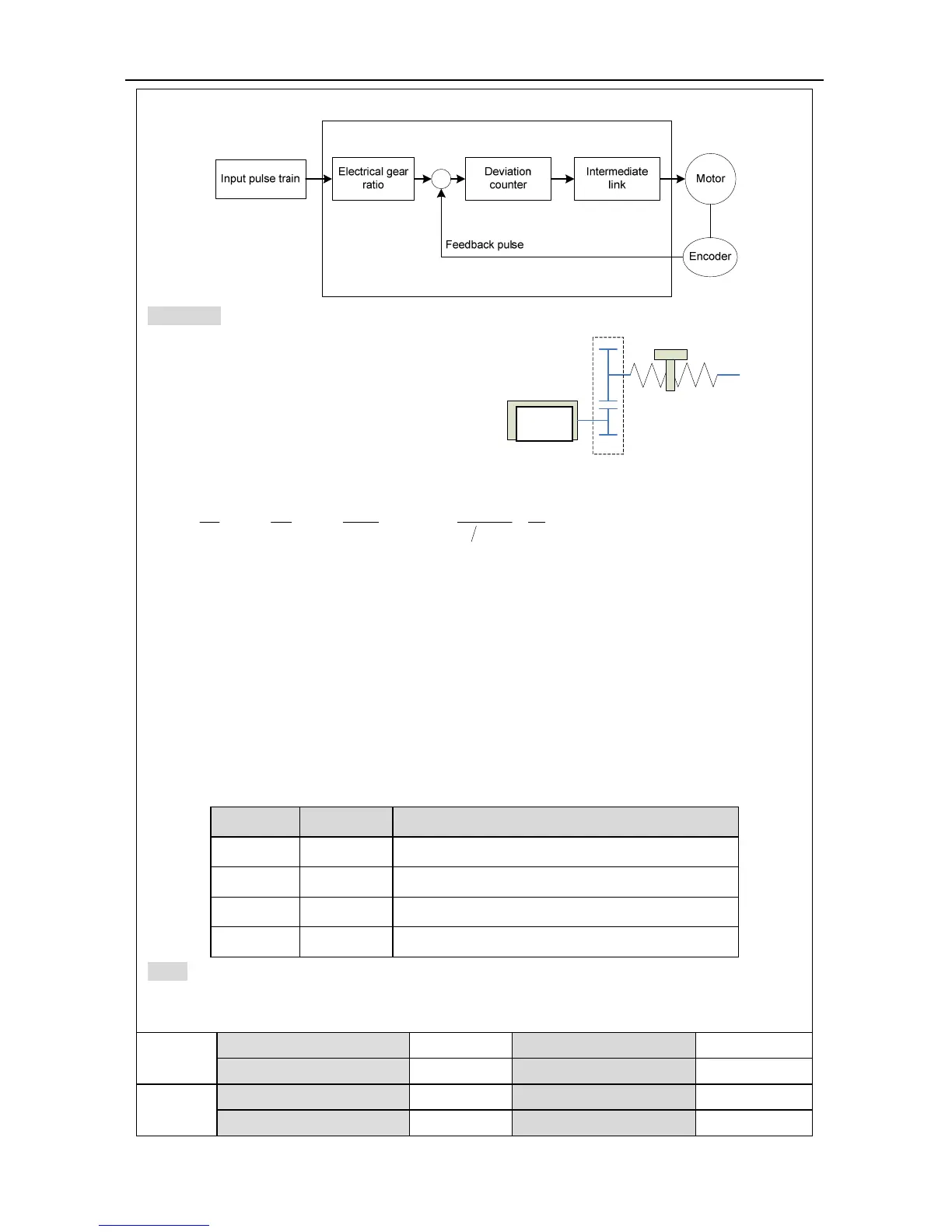

Example: Below is a case where 1 pulse is

equivalent to a feed rate of 10μm

Mechanical specifications:

Feed of the ball screw Pb =10mm;

Reduction ratio n=3/5;

Resolution of the servo motor encoder =10000;

At this time calculate the electronic gear ratio:

3

00

1 10000 50

10 10

2(35)103

gPt Pt

gSnPb

In the formula :

0

: Feed rate corresponding to each pulse (mm/pulse);

S : Feed rate corresponding to each rotation of the motor (mm/rot).

i.e. in this example, g1=50, g2=3.

Set P0.25 to 50 and P0.26 to 3.

The servo drive has 4 groups of electric gear ratio: P0.25, P0.26, P0.27 and P0.28, P0.29 can

select to adopt which parameter group to provide the electronic gear ratio through the digital

input configured as electronic gear ratio selection function (SC1, SC2) on CN1,plug, the

corresponding relation is shown below:

SC1 SC2 Position mode/Fully-closed loop mode

0 0 Numerator of 1

st

electronic gear ratio

1 0 Numerator of 2

nd

electronic gear ratio

0 1 Numerator of 3

rd

electronic gear ratio

1 1 Numerator of 4

th

electronic gear ratio

Note:

1. The parameters are valid when P0.22

1

is 0.

2. Switch the electronic gear ratio via digital quantity (SC1, SC2), P4.10 must be set to 0.

P0.25

Data size 32bit Data format DEC

Modbus address 1050,1051 CANopen address 0x2019, 0x00

P0.26

2

Data size 32bit Data format DEC

Modbus address 1052,1053 CANopen address 0x201A, 0x00

伺服电机

n

Servo

motor

Loading...

Loading...