Page: 16

MV & LV SERIES ENGINEERED DRY CHEMICAL FIRE EXTINGUISHING SYSTEM

OPERATION, DESIGN, & SERVICE MANUAL

REV C

Document # DOC324

Issued: April 26, 2018

Revised: March 22, 2022

UL FILE # EX27541

Section 2 System Components and Description

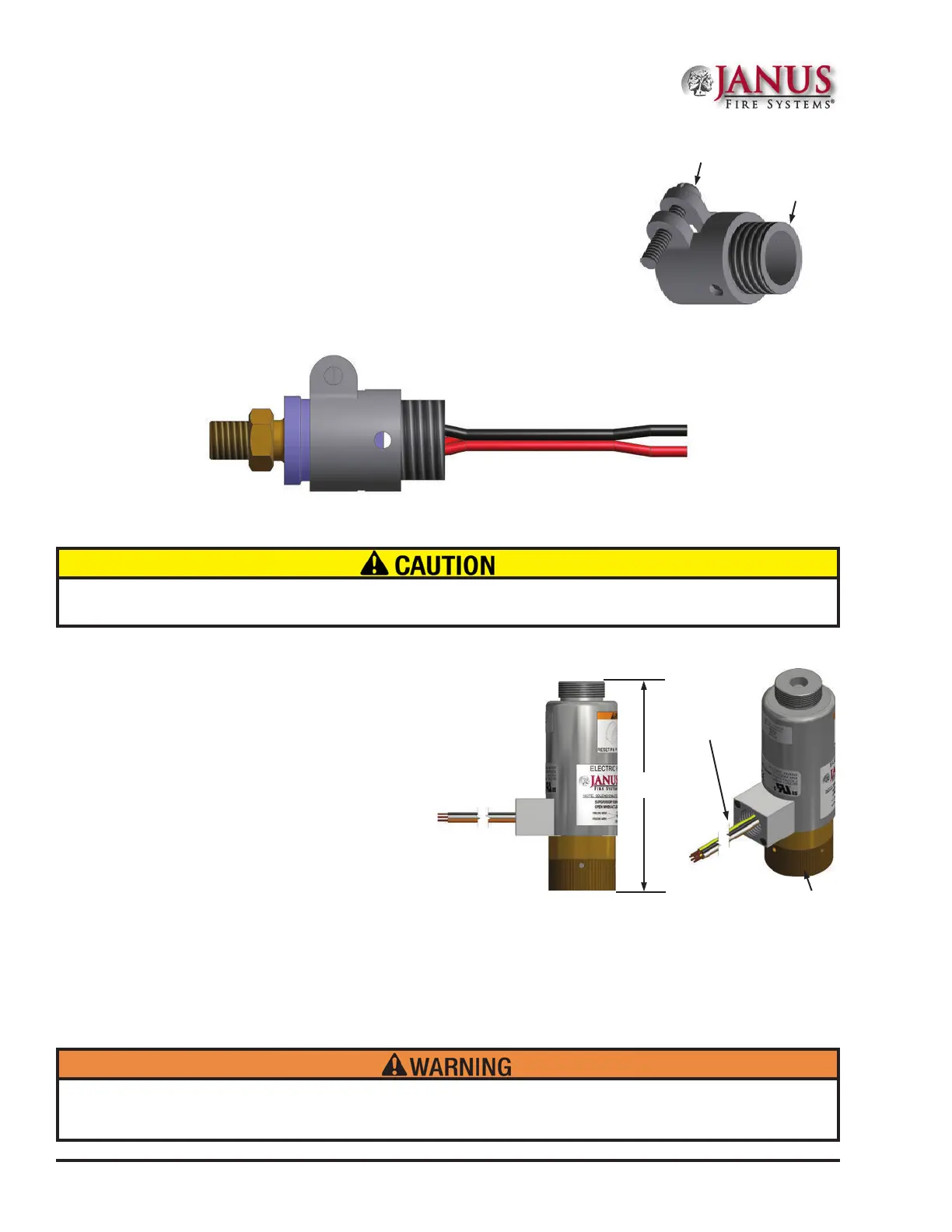

Figure 2.2.3a Electric Valve Actuator

Knurled Swivel Nut

1/2” (15 mm) NPS Female

Conduit Hub

with 40” (1016 mm) leads

1/2" (15 mm) NPS

Male Conduit

Connection

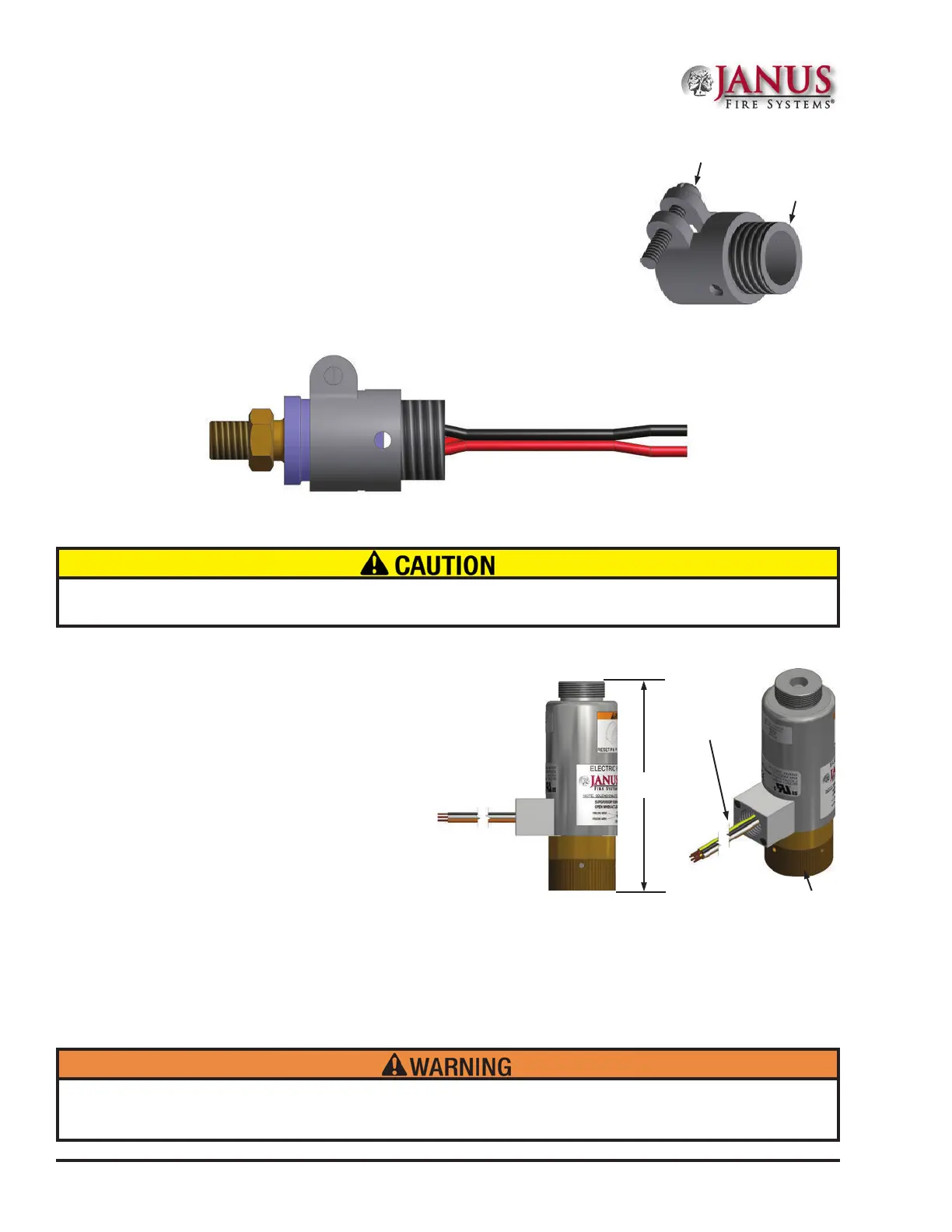

Figure 2.2.2.1a Low-Pressure

Supervisory Switch Conduit Adapter

Figure 2.2.2.1b Low-Pressure Supervisory Switch w/ Conduit Adapter (Sv Series Shown)

Attaching the electric valve actuator to the cylinder valve or remote actuation cylinder when the actuation pin is

not fully locked into the “up” position may cause the cylinder valve to actuate, resulting in potential injury and/or

property damage.

The conduit adapter fastening screw shall NOT be overtightened. Overtightening the fastening screw may cause

the body of the low-pressure supervisory switch to crack.

NOTE: Conduit Adapter must be ordered sepa-

rately from the low-pressure supervisory switch

andeldinstalledasshownhere.

2.2.2.1 Low-Pressure Supervisory Switch Conduit Adapter

P/N 99408 (See Figure 2.2.2.1a and 2.2.2.1b)

An optional conduit adapter is available for the low-pressure supervisory

switch to facilitate the attachment of rigid or flexible conduit over the

switch leads. When implemented, the adapter shall be field installed to

the body of the low-pressure supervisory switch and the fastening screw

secured until the conduit adapter fits snuggly around the low-pressure

supervisory switch body as illustrated in Figure 2.2.2.1b.

2.2.3 Electric Valve Actuator w Limit Switch

P/N 20722 (See Figure 2.2.3a)

e electric valve actuator attaches to the

primary cylinder at the valve actuation

connection in a single cylinder system or the

remote nitrogen actuation cylinder in multiple

cylinder system. It is utilized to automatically

open the cylinder valve upon receipt of a

signal from the control panel or other source.

It operates between 20.4 and 26.4 VDC and

consumes 500 mA (.5 Amps) at 24 VDC

nominal with a maximum supervisory current

of 30 mA (0.03 Amps).

e electric valve actuator body is steel construction with a brass knurled swivel nut and a stainless steel actuation

pin that depresses the valve core when energized. It must be manually reset by pushing the pin up until it snaps in

the “up” position. e electric valve actuator is shipped with a plastic threaded cap on its top port that should only

be removed when installing the manual valve actuator. e electric valve actuator has a life span of 25 years from

date of manufacture.

5.11 in

129.8 mm

Fastening Screw

Loading...

Loading...