Page: 64

MV & LV SERIES ENGINEERED DRY CHEMICAL FIRE EXTINGUISHING SYSTEM

OPERATION, DESIGN, & SERVICE MANUAL

REV C

Document # DOC324

Issued: April 26, 2018

Revised: March 22, 2022

UL FILE # EX27541

3.5 Pipe Determination

Pipe sizes must be determined using the Janus

Design Suite® flow calculation software.

Table 3.5 may be referenced for the purposes

of estimation. e actual diameters may vary

due to distance or software optimization.

Flowcalculationshavebeenveriedatanambienttemperatureof70°F(21.1°C).Storageoutsideoftherange

of70°F±10°(21.1°C±5.5°)mayresultininaccurateowcalculationsandcauseoneormorenozzlestonot

discharge the designed quantity of dry chemical agent.

Flowcalculationshavebeenveriedforspecictypesofttings,pipeandpipeID.Failuretomaintaintheveried

limitationsasstatedintheJanusDesignSuite®FlowCalculationSoftwareManualmayresultininaccurateow

calculations and cause one or more nozzles to not discharge the designed quantity of dry chemical agent.

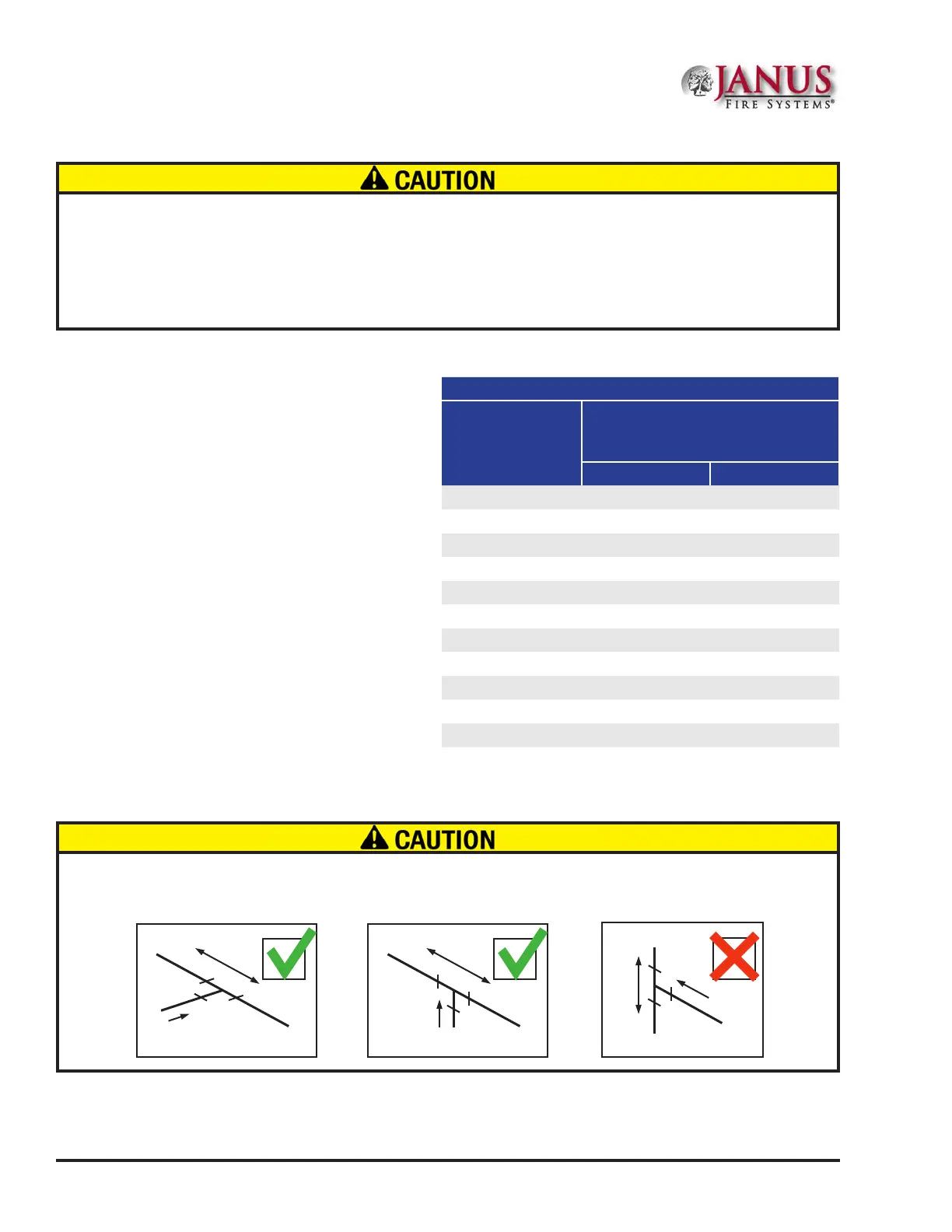

The outlets of a tee branch must be on the same horizontal plane or an imbalance will result from the gravitational

eectsofthesolidandvaporseparationandmaycauseoneormorenozzlestonotdischargethedesigned

concentration of dry chemical agent.

IN

OUT

OUT

OUT

IN

IN

OUT

OUT

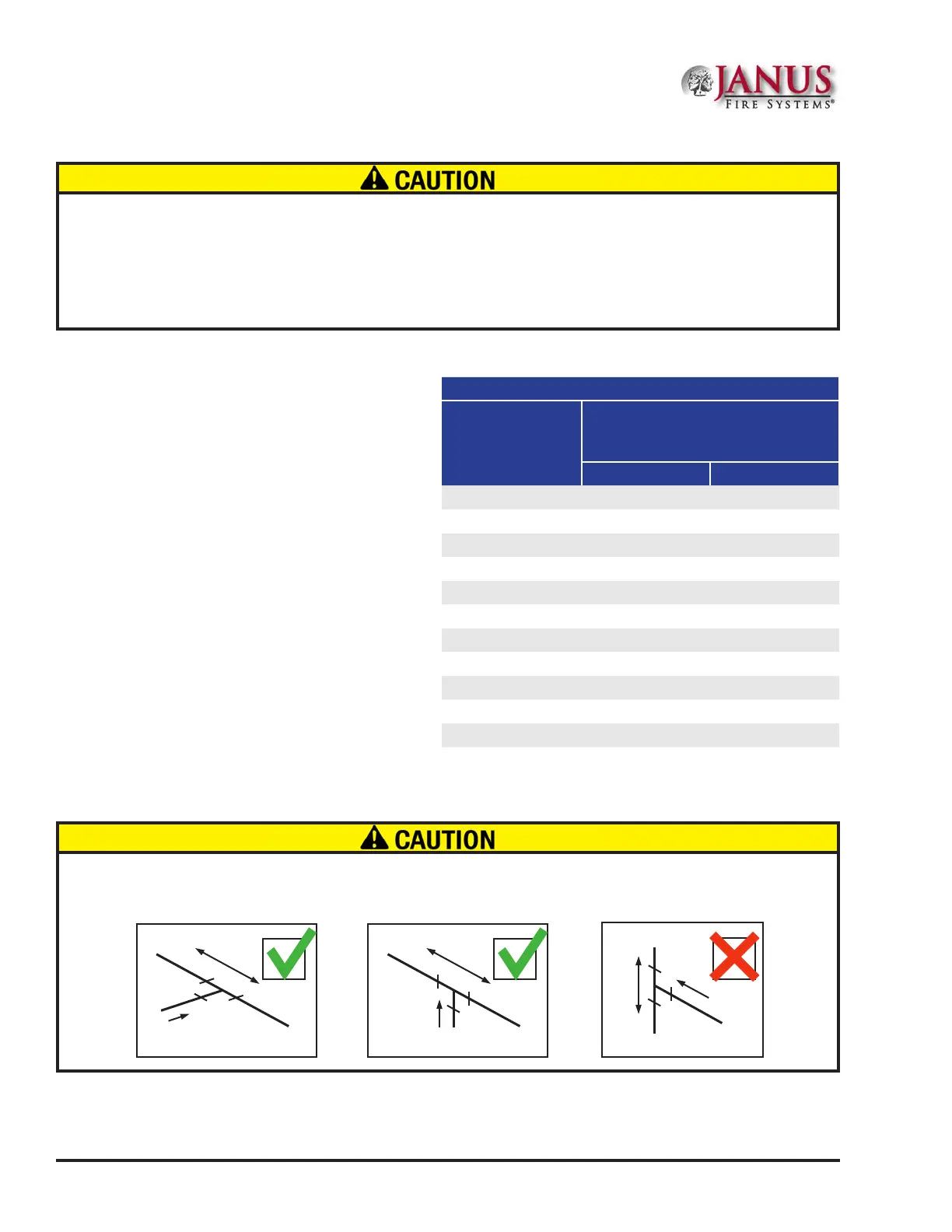

Table 3.5 - Pipe Size vs. Flow Rate

Schedule 40

Pipe Size Nomi-

nal Inches (mm)

Minimum Flow

Rate For All

Sections Leading to a Tee

Lbs/Min Kg/Min

3/8 (10) 46.5 21.1

1/2 (15) 77.4 35.1

3/4 (20) 136.2 61.8

1 (25) 219 99.3

1 1/4 (32) 380.4 172.5

1 1/2 (40) 523.8 237.6

2 (50) 894.6 405.8

2 1/2 (65) 1321.8 599.5

3 (80) 2140.2 970.8

4 (100) 3878.4 1759.2

6 (150) 8596.2 3899.2

Section 3 System Design

Loading...

Loading...