Page: 61

MV & LV SERIES ENGINEERED DRY CHEMICAL FIRE EXTINGUISHING SYSTEM

OPERATION, DESIGN, & SERVICE MANUAL

REV C

Document # DOC324

Issued: April 26, 2018

Revised: March 22, 2022

UL FILE # EX27541

3.4.2 Agent Application

e nozzles used in protecting Open Front Paint Spray Booth applications are listed in Table 3.4.2 below

along with the minimum amount of dry chemical agent per second each nozzle must discharge in this usage

(minimum flow rate). e Janus Design Suite® Flow Calculation Software will determine the amount of

dry chemical agent required to meet these flow rates based on the hazard dimensions and number of nozzles

required.

3.4.3 Open Front Paint Spray Booths (OFPSB) Nozzle Coverages

3.4.3.1 Work Area and Plenum, OFPSB

e Janus Fire Systems® Engineered Dry Chemical System is flexible enough to protect a wide variety of

Open Front Booth dimensions. e maximum parameters for each Module are given on Table 3.4.3.1a and b.

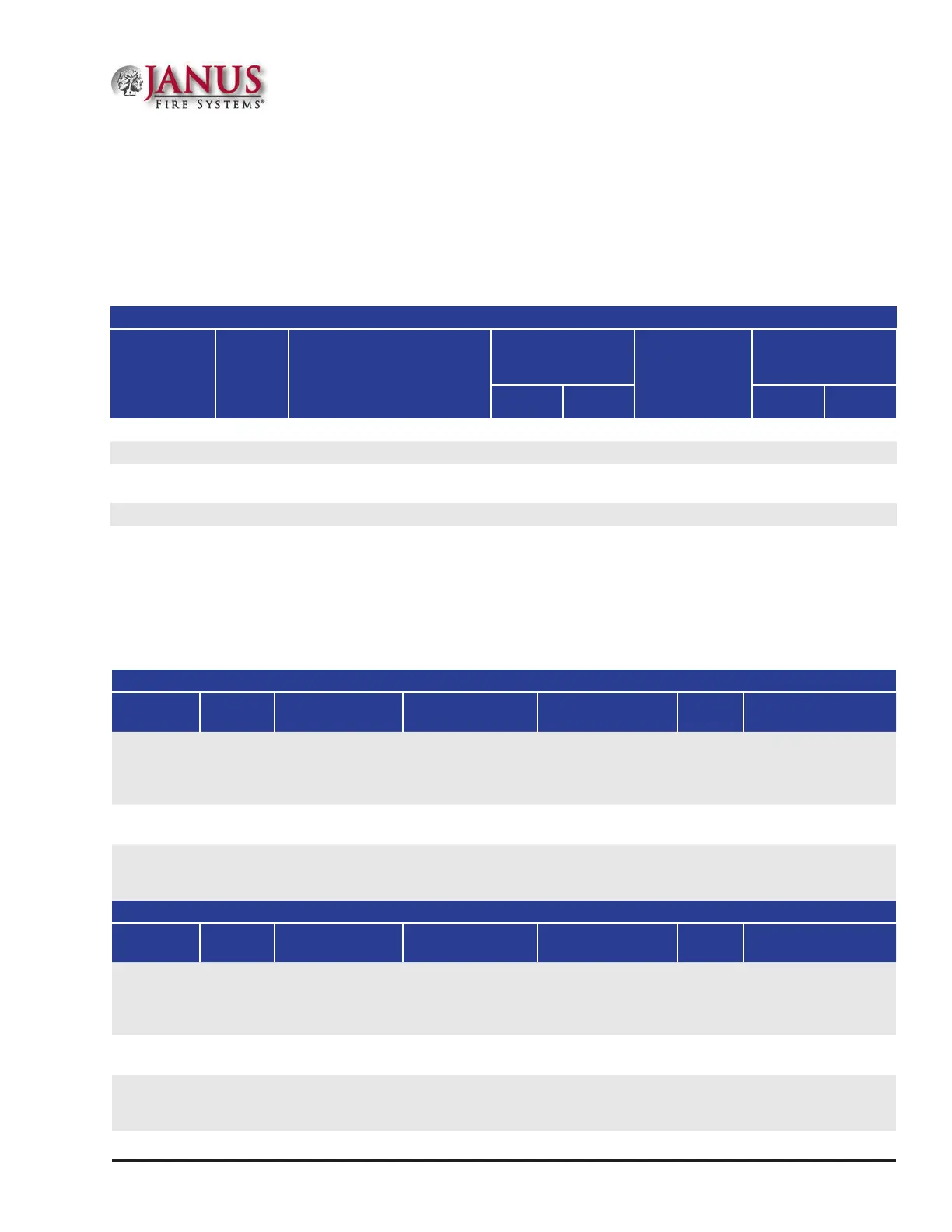

Table 3.4.3.1a Work Area and Plenum Coverage, OFPSB

Protection

Nozzle

Used

Dimensions Per

Nozzle L x W x H

Maximum

Specications

Nozzle Location

Nozzle

Oset*

Nozzle Orientation

Screening

SCR

(PN 16192)

-- x 8 ft x 18 ft

6 in

Side = 8 ft

Length: At Front

Edge

Width: Center

0 in to

6 in

Vertical, Pointing

downward; nozzle

holes parallel with

booth front

Work Area

TF

(PN 16172)

8 ft x 8 ft x 18 ft

6 in

Area = 64 ft²

Side = 8 ft

Length: Center

Width: Center

0 in to

6 in

Vertical, Pointing

Downward

Plenum

TF

(PN 16172)

4 ft x 8 ft x 18 ft

6 in

Volume = 384 ft³

Area = 32 ft²

Side = 8 ft

Length: Center

Width: Center

0 in to

6 in

Vertical, Pointing

Downward

Table 3.4.3.1b Work Area and Plenum Coverage, OFPSB, metric

Protection

Nozzle

Used

Dimensions Per

Nozzle L x W x H

Maximum

Specications

Nozzle Location

Nozzle

Oset*

Nozzle Orientation

Screening

SCR

(PN 16192)

-- x 2438 mm x

5639 mm

Side = 2438 mm

Length: At Front

Edge

Width: Center

0 mm to

152 mm

Vertical, Pointing

downward; nozzle

holes parallel with

booth front

Work Area

TF

(PN 16172)

2438 mm x 2438

mm x 5639 mm

Area = 5.94 m²

Side = 2438 mm

Length: Center

Width: Center

0 mm to

152 mm

Vertical, Pointing

Downward

Plenum

TF

(PN 16172)

1219 mm x 2438

mm x 5639 mm

Volume = 10.27 m³

Area = 2.97 m²

Side = 2438 mm

Length: Center

Width: Center

0 mm to

152 mm

Vertical, Pointing

Downward

*NozzleOsetisthemaximumdistancefromthetipofthenozzletothenearestedgeoftheprotectedzone.

Section 3 System Design

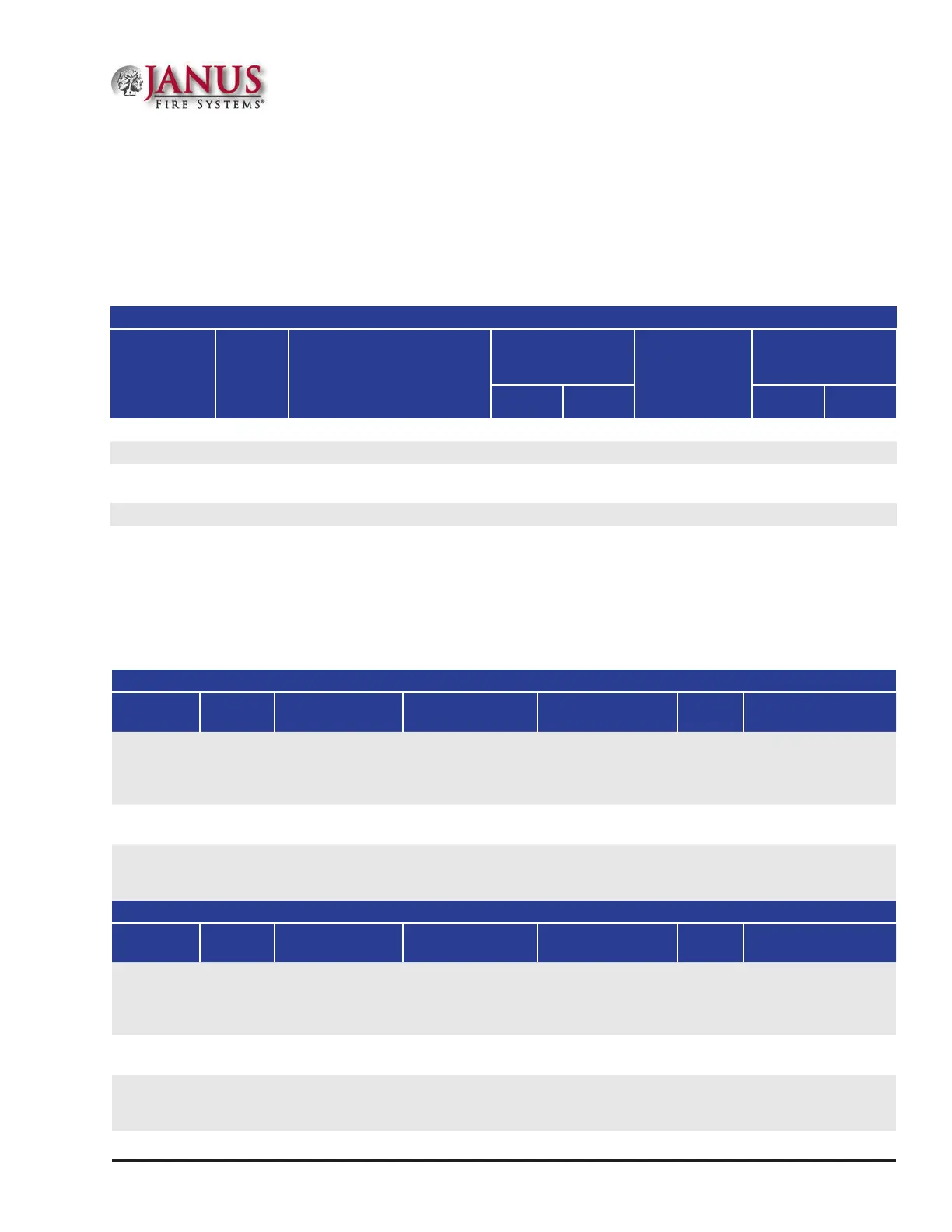

Table 3.4.2 OFPSB Nozzle Application and Minimum Flow Rates

Nozzle Type PN Application

Minimum Flowrate Minimum

Discharge Time

(sec)

Minimum Agent

Discharged

Per Nozzle

lb/s kg/s lbs kg

TF Nozzle 16172 Work Area 2.07 0.94 4.2 8.7 3.95

TF Nozzle 16172 Plenum 2.19 0.99 4.2 9.2 4.16

SCR Nozzle 16192

Screening the opening of

the Work Area

2.12 0.96 4.2 8.9 4.03

D/P Nozzle 16190 Exhaust Duct 2.04 0.93 4.2 8.57 3.91

Loading...

Loading...