Page: 39

MV & LV SERIES ENGINEERED DRY CHEMICAL FIRE EXTINGUISHING SYSTEM

OPERATION, DESIGN, & SERVICE MANUAL

REV C

Document # DOC324

Issued: April 26, 2018

Revised: March 22, 2022

UL FILE # EX27541

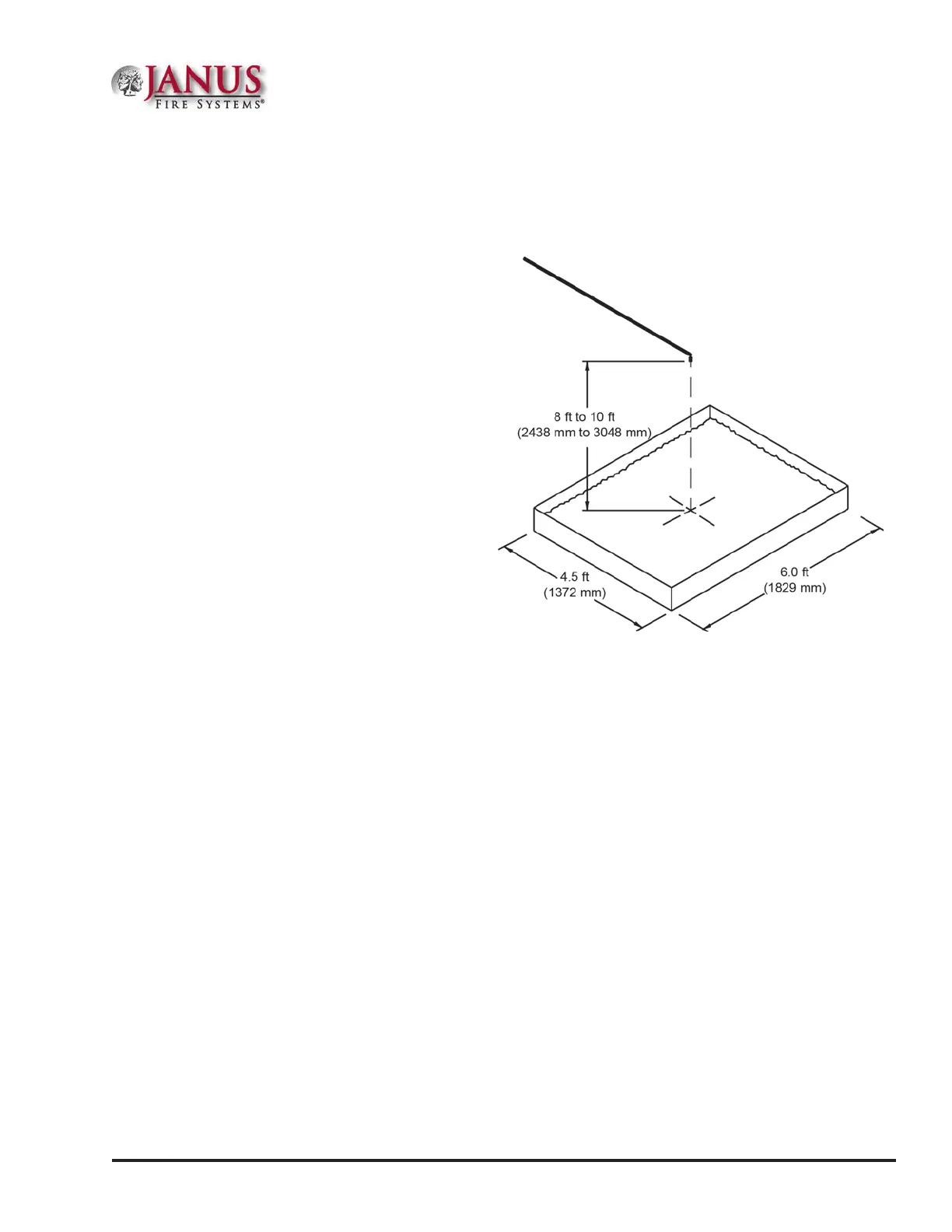

Figure 3.2.1 Nozzle Placement for

Overhead Local Application

3.2.1 Local Application - Overhead

An overhead local application system is used for applying dry chemical, discharged from above, directly

onto a burning hazard. Typical applications include dip tanks, power generators and transformers.

3.2.1.1 Nozzle Orientation

e Local Application Overhead Nozzle

(LAOH Nozzle) (P/N 16216) has been

developed to provide local application of

extinguishing agent from an overhead position.

Each nozzle will protect a hazard area of 27 ft²

(2.5 m²) with a 6 ft (1829 mm) maximum side.

e maximum nozzle height is 10 ft (3048 mm).

e minimum nozzle height is 8 ft (2438 mm)

(for fuel in depth splash hazards). Note: Nozzle

height is measured from the hazard surface to

the closest point of the nozzle in the installed

position.

3.2.1.2 Temperature Limitations

e operating temperature range for the

system components used in Local Overhead

applications is 32°F to 120°F (0°C to 49°C).

3.2.1.3 Agent Application

Each LAOH Nozzle must discharge a minimum of 1.5 lbs (0.68 kg) of dry chemical agent per second

(a minimum flow rate of 1.5 lb/s (0.68 kgs/s)). Additionally, in protecting hazards where splashing may

occur, each LAOH Nozzle cannot discharge more than 2.25 lbs (1.02 kg) of dry chemical agent per second

(a maximum flow rate of 2.25 lb/s (1.02 kg/s)). e Janus Design Suite® Flow Calculation Software

will determine the amount of dry chemical agent required to meet these flow rates based on the hazard

dimensions and number of nozzles required.

Section 3 System Design

Loading...

Loading...