CONTROL SYSTEM

TC-15001-rev.3

6-59

6.8.7.3 Preparation at the Site

Before installing a controller, prepare the following items.

Parts 6SHFL¿FDWLRQ

Steel Box Option

Power Supply

Cable

&DEOH63(&$:*PP

2

) to AWG 14(2mm

2

)

5HFRPPHQGHG&DEOH9&9&&9&(9

H-LINK Cable

(For Control)

&DEOH63(&$:*PP

2

) to AWG 16(1.25mm

2

)

5HFRPPHQGHG&DEOH-.(396-.(96&996&9999&7

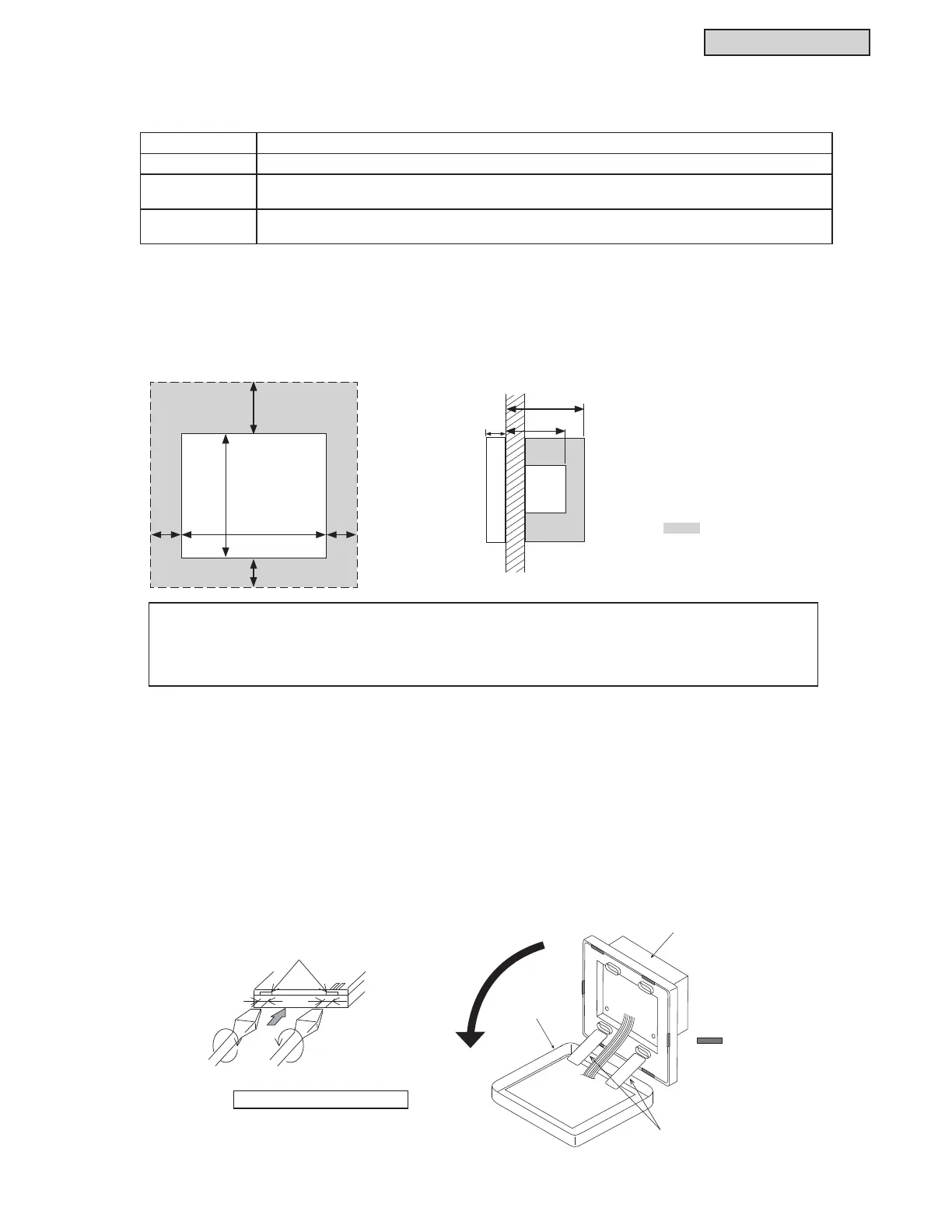

[Installation Space]

Provide the installation space for the mini central controller as shown below.

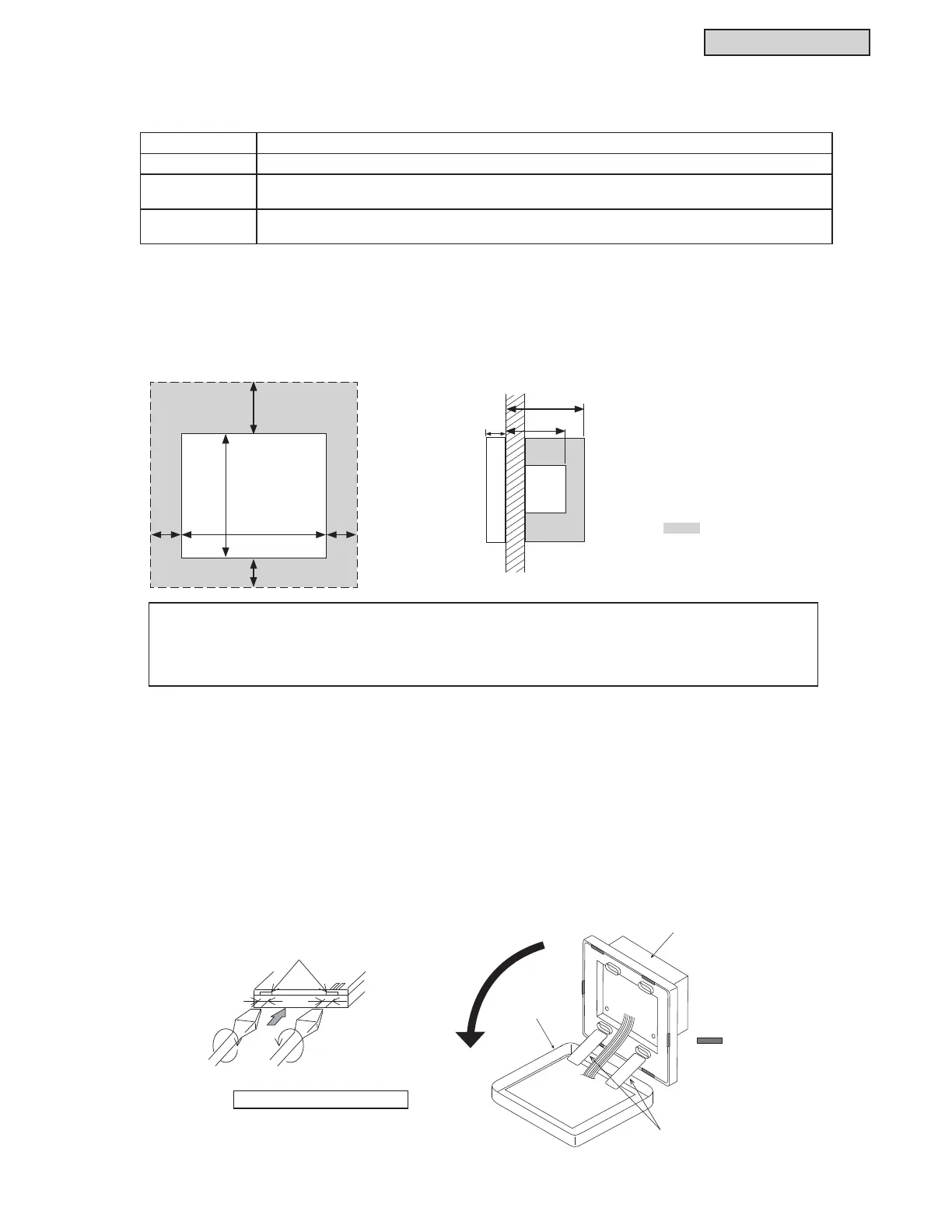

[Installation Method]

1) Install the steel box (option) into the wall.

2) Open the unit body. (The factory ships the unit open.)

If the unit is closed, open it as shown below.

(a) Remove the convex part of the case by pressing and rotating a screwdriver in the cut-out portions (two

cut-out portions on the convex part).

(b) When pulling up the convex part of the case, the copper will separate from the upper side and

ODWHUDOVLGHVRWKHFRYHUZLOORSHQ7KHXSSHUDQGORZHUFDVHZLOOEH¿[HGZLWKDFRQQHFWLRQEDQG

Do not use excessive force to open the case.

Note: Communication cabling shall be a minimum of 18-Gauge, 2-Conductor, Stranded Copper. Shielded cable

PXVWEHFRQVLGHUHGIRUDSSOLFDWLRQVDQGURXWLQJLQDUHDVRIKLJK(0,DQGRWKHUVRXUFHVRISRWHQWLDOO\H[FHVVLYH

electrical noise to reduce the potential for communication errors. When shielded cabling is applied, proper bonding

and termination of the cable shield is required as per Johnson Controls guidelines. Plenum and riser ratings for

communication cables must be considered per application and local code requirements.

:KHQLQVWDOOLQJPRUHWKDQWZRPLQLFHQWUDOFRQWUROOHUVLQDURZRULQOLQHNHHSWKHVSDFHEHWZHHQHDFK

Ɠ Vertical Direction: 2 inches (51mm)

Ɠ Horizontal Direction: 1-3/16 inch (30mm)

Unit: inch (mm)

7/8

(22)

2-3/32 (53)

2-3/4(70)

2(51)

4-9/16

(120)

5-9/16 (141)

1-3/16

(30)

1-3/16

(30)

1-3/16(30)

Do not attach anything

in the shaded screen

area “

´

Convex Part

Approximately

1 inch (6mm)

Slotted Screw Driver

View from Lower Side

: Latch fo

Closing

Connection Band

Lower Case

Upper Case

Loading...

Loading...