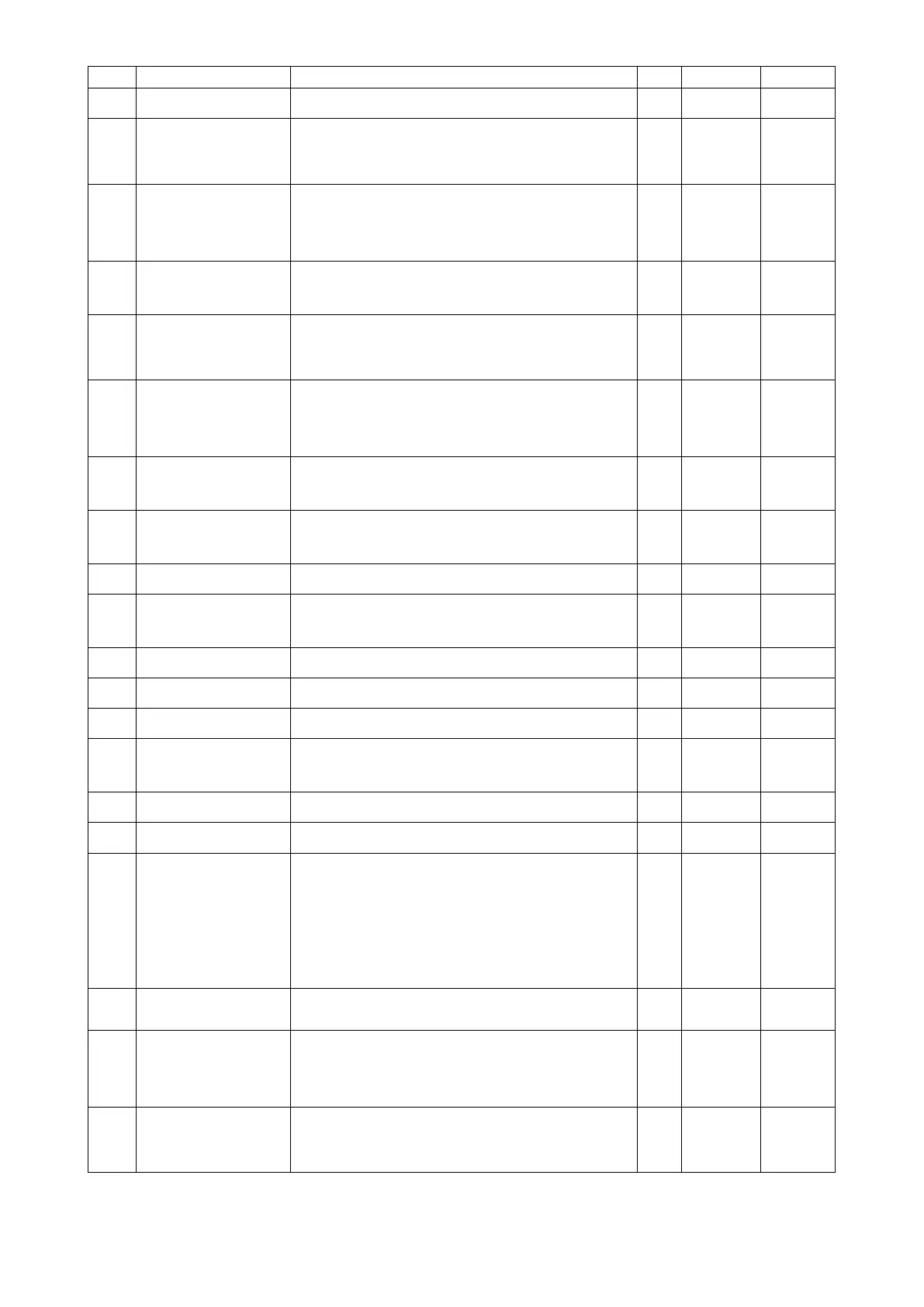

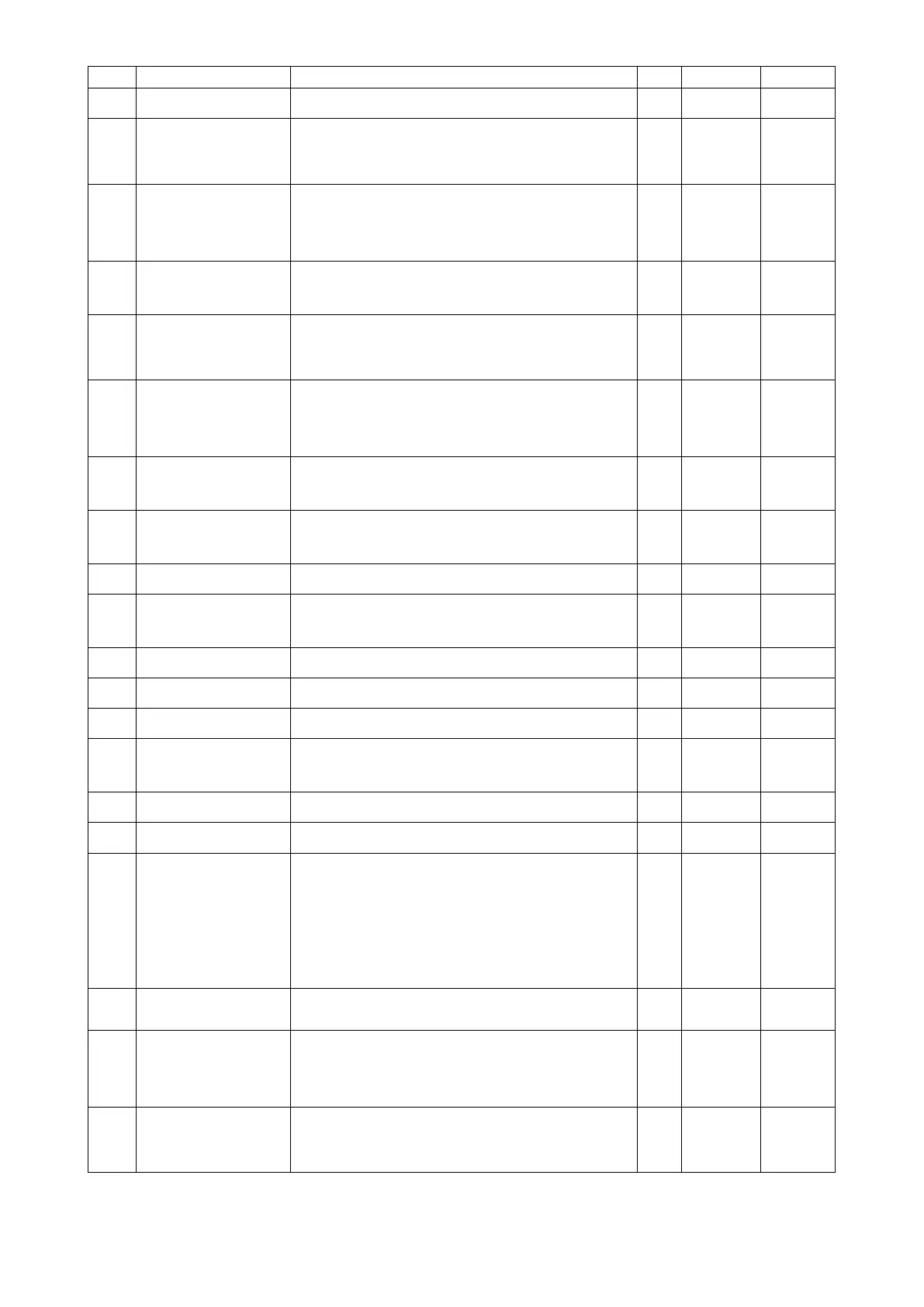

No. Item Description Level Setting range Default

*

P24 Position to perform thread

trimming by pedal

The position to perform thread trimming by operating the pedal is

set with this function setting item.

S 30-500 130

P25 Correction of solenoid-on

timing for the reverse feed

stitching at the end of sew-

ing

Stitch alignment can be carried out by changing the timing of

actuating the reverse-feed stitching solenoid at the time of reverse

feed stitching at the end of sewing. When the set value for this

parameter is increased, the length of stitch at the beginning of C

process is increased.

U 0-200 123

P26 Correction of solenoid-o

timing for the reverse feed

stitching at the end of sew-

ing

Stitch alignment can be carried out by changing the timing of

releasing the reverse-feed stitching solenoid at the time of reverse

feed stitching at the end of sewing. When the set value for this pa-

rameter is increased, the length of stitch at the end of C process

is decreased and the length of stitch at the beginning of D process

is increased.

U 0-200 130

*

P29 Brake force of the main

shaft at the time of stopping

the sewing machine after

thread trimming

Main shaft brake force is adjusted with this function setting item

for preventing the sewing machine from overrunning before stop-

ping.

S 1-45 30

P32 Correction of solenoid-on

timing for the overlapped

stitching

Stitch alignment can be carried out by changing the timing of actu-

ating the reverse feed stitching solenoid at the time of overlapped

stitching. When the set value for this parameter is increased, the

length of stitch at the end of A (C) process is increased and the

length of stitch at the beginning of B process is decreased.

U 0-200 MS

:

105

SH

:

92

P33 Correction of solenoid-o

timing for the overlapped

stitching

Stitch alignment can be carried out by changing the timing

of releasing the reverse-feed stitching solenoid at the time of

overlapped stitching. When the set value for this parameter is

increased, the length of stitch at the end of B process is increased

and the length of stitch at the beginning of C process is de-

creased.

U 0-200 MS

:

105

SH

:

100

P37 First current value (ON duty)

of thread clamp

The rst current value (ON duty) for the thread clamp is set with

this function setting item.

* Refer to the "explanation of the thread clamp solenoid opera-

tion" in the Engineer's Manual for details.

U 0-100 MS

:

40

SH

:

50

*

P44 Brake force of the main

shaft at the time of stopping

the sewing machine on the

way

Main shaft brake force is adjusted with this function setting item

for preventing the sewing machine from overrunning before stop-

ping on the way.

S 1-45 16

P45 ON duty of the reverse feed

stitching solenoid

Output duty of the reverse feed stitching solenoid when the sole-

noid is in the ON state is set with this function setting item.

S 1-50 30

P46 Setting of the function of

reverse revolution to lift the

needle

This function rotates the main shaft in the reverse direction of

sewing to bring the needle bar to the highest position.

ON: Reverse-revolution operation is in the ON state

OFF: Reverse-revolution operation is in the OFF state

U ON/OFF OFF

P47 Reverse revolution angle to

lift the needle

The operating angle of the reverse-revolution to lift the needle is

adjusted with this function setting item.

S 50-200

(1/4°)

160

P48 Sewing speed at a low

speed

The minimum sewing speed of the sewing machine by operating

the pedal is set with this function setting item.

U 100-500

(sti/min)

200

P49 Sewing speed for thread

trimming

Sewing speed to be used when performing thread trimming is set

with this function setting item.

U 100-500

(sti/min)

210

*

P50 2nd thread trimming speed Sewing speed is decreased in the latter half of thread trimming

operation. That sewing speed is set with this function setting item.

* In the case this speed is set to "0" (zero), the sewing machine

runs at the 1st thread trimming speed.

S 0-500

(sti/min)

180

*

P51 Timing to change over to the

2nd thread trimming speed

The timing to change over the sewing speed to the 2nd thread

trimming speed is set with this function setting item.

S 270-370(°) 320

*

P52 Time to wait for sewing after

lowering the presser foot

The time to wait for starting sewing after the presser foot is low-

ered is set with this function setting item.

S 10-500(ms) 120

P53 Setting of operation of the

presser foot when the back

part of pedal is depressed

The operation of the presser foot when the back part of pedal is

depressed is set with this function setting item.

0: Presser foot does not operate even when the back part of

pedal is depressed.

1: Presser foot goes up to the 1st presser-foot lifting position

when the back part of pedal is depressed by half of the depth.

It goes up to the 2nd presser-foot lifting position when the

back part of the pedal is further depressed.

2: Presser foot does not operate even when the back part of

pedal is depressed. It goes up to the 2nd presser-foot lifting

position when the back part of the pedal is further depressed.

U 0-2 1

P68 Maximum sewing speed The maximum sewing speed is set with this function setting item.

(The MAX value diers with the type of machine head.

MS: 5000; SH: 4500)

S 100-MAX

(sti/min)

MS

:

4000

SH

:

3500

P70 Machine head selection

(Initialization of data)

Machine head type is selected with this function setting item.

2: DDL-8000APMS

3: DDL-8000APSH

* When you select the corresponding machine head and press

the enter switch, all existing data are initialized to the initial

values for the machine head you have selected.

S 2-3 2

P72 Adjustment mode for the

needle-up stop angle

The current main shaft angle is always displayed in the data

display section. When you turn the pulley to bring the main shaft

to the needle-up stop position and press the enter switch, the

needle-up angle and needle-down angle of the main shaft are

automatically set.

S 0-1439

(1/4°)

*

Do not change the set values with asterisk (*) mark as they are functions for maintenance. If the standard set value set at the time

of delivery is changed, it is in danger of causing the machine to be broken or the performance to be deteriorated. If it is necessary to

change the set value, please purchase the Engineer’s Manual and follow the instructions.

– 38 –

Loading...

Loading...