– 20 –

Switch "OFF" the motor.

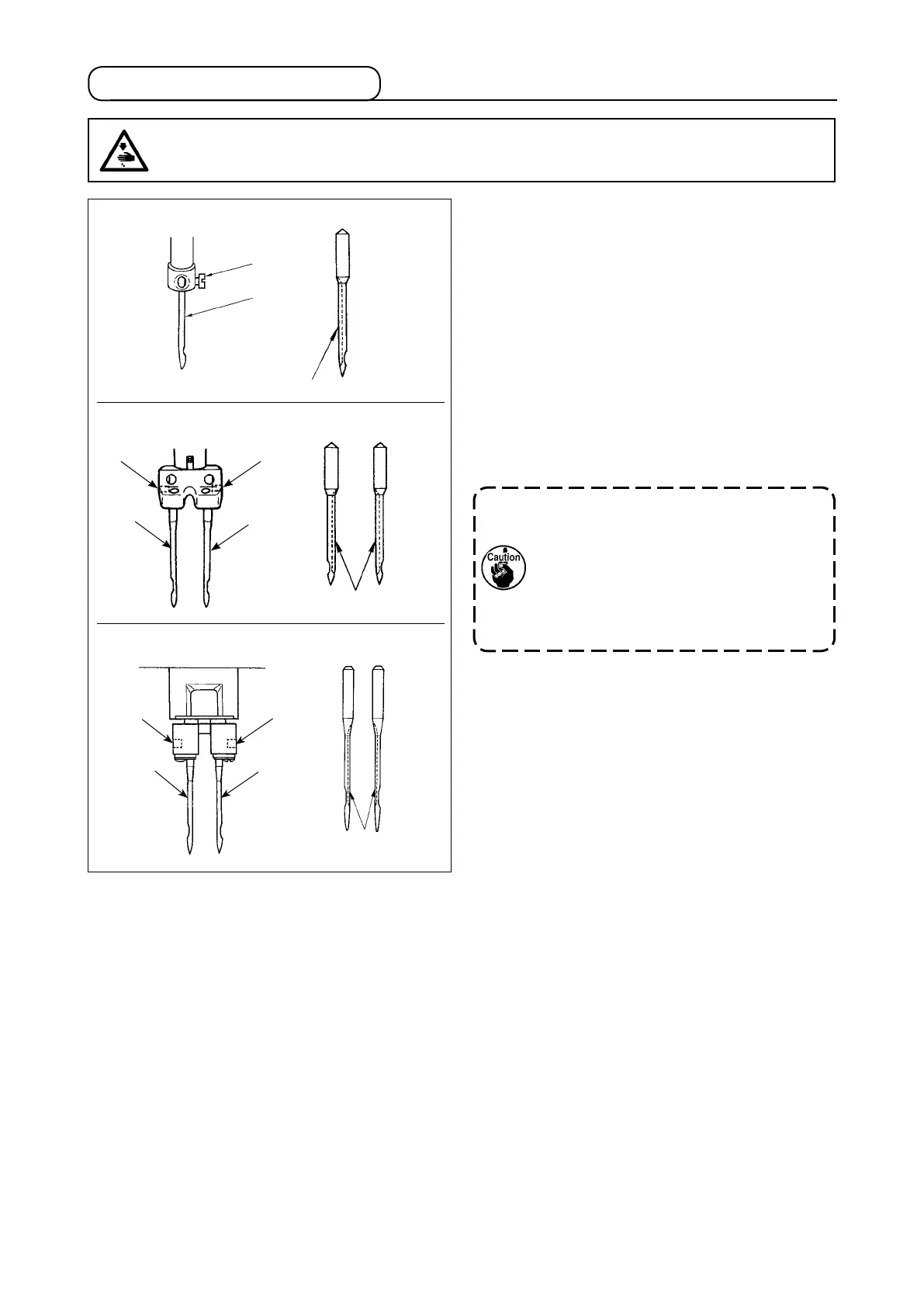

Use 135x17 needles.

1) Turn the handwheel to bring the needle bar to the

highest position of its stroke.

2) Loosen needle clamp screw . Hold the needle

so that the long groove on needle faces directly

to the right for the PLC-2710 and -2710-7, and

so that the long groove on each the two needles

faces inward for the PLC-2760, -2760-7, -2760L,

and -2765.

3) Push needle deep into the needle clamp hole

until it will go no further.

4) Tighten needle clamp screw rmly.

When replacing the needle, check the

clearance provided between the needle

and the blade point of hook. (Refer to "4-4.

Needle-to-hook relation" p.30 and "4-5.

Adjusting the hook needle guard" p.31.)

If there is no clearance, the needle and the

hook will be damaged.

WARNING :

To protect against possible personal injury due to abrupt start of the machine, be sure to start the

following work after turning the power off and ascertaining that the motor is at rest.

PLC-2710, 2710-7

PLC-2760, 2760-7, 2760L

PLC-2765

Long groove

Long groove

Long groove

3-6. Attaching the needle

Loading...

Loading...