– 32 –

In case of 2-needle machine, perform

the same adjustment to the right and left

hooks.

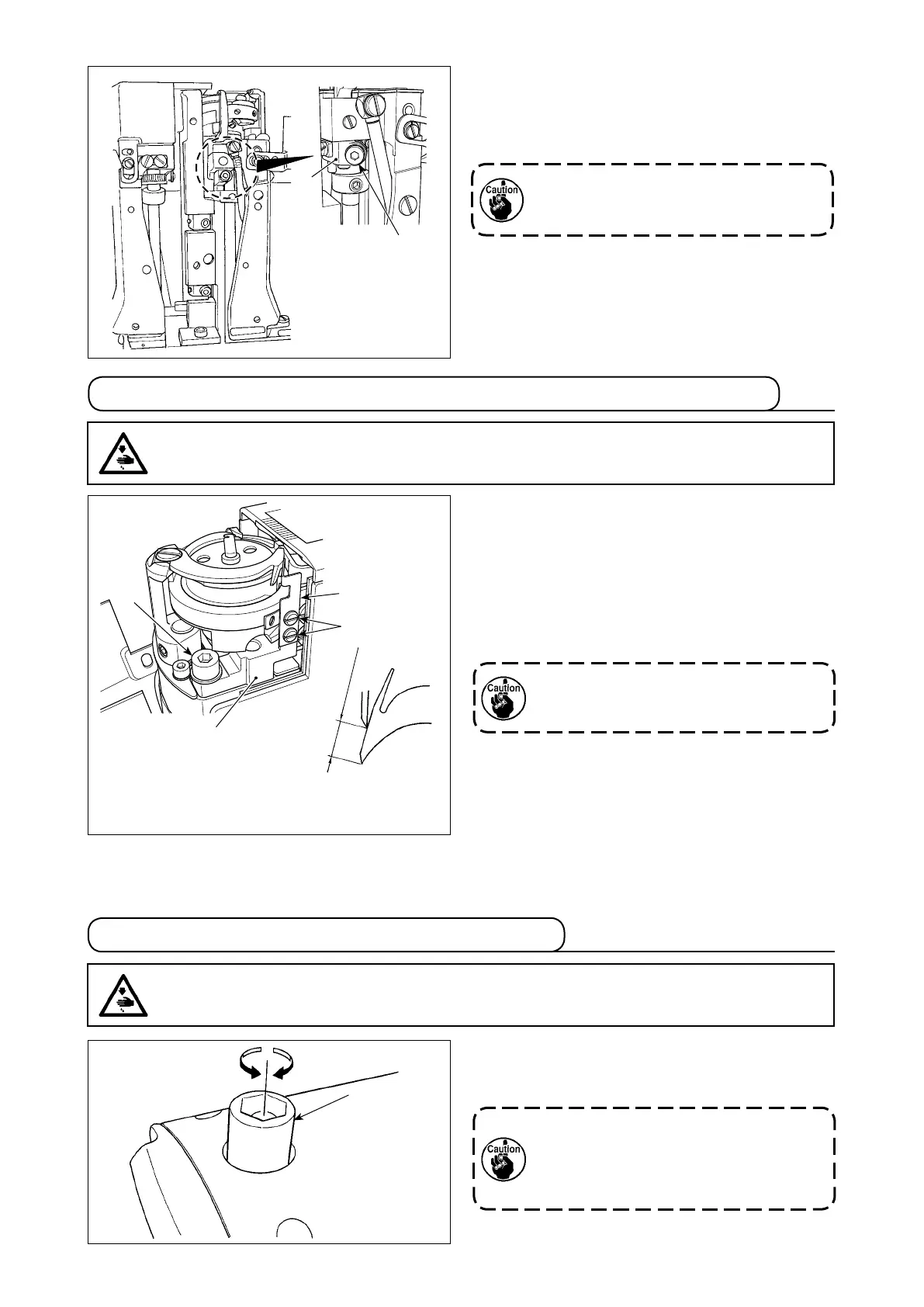

• Adjusting the knife pressure

1) Move the moving knife by hand to its forward travel

end.

2) Loosen setscrew in the counter knife base.

Adjust, as standard, so that the knife pressure is

applied when counter knife base is turned until

the top end of the counter knife is spaced 5 to 7

mm from the top end of the moving knife.

• Adjusting the clamp spring

1) Move the moving knife to the initial position.

2) 2) Loosen clamp spring setscrews . At the posi-

tion where clamp spring lightly comes in contact

with the moving knife, press the undersurface of

the spring against counter knife base . In this

state, x the clamp spring with setscrews .

Be sure to carefully prevent from get-

ting injured by the moving knife, counter

knife, blade point of the hook, etc.

Knife pres

-

sure starts

to be devel

-

oped.

WARNING :

To protect against possible personal injury due to abrupt start of the machine, be sure to start the

following work after turning the power off and ascertaining that the motor is at rest.

5 to 7mm

4-7. Position of the counter knife and adjustment of the knife pressure

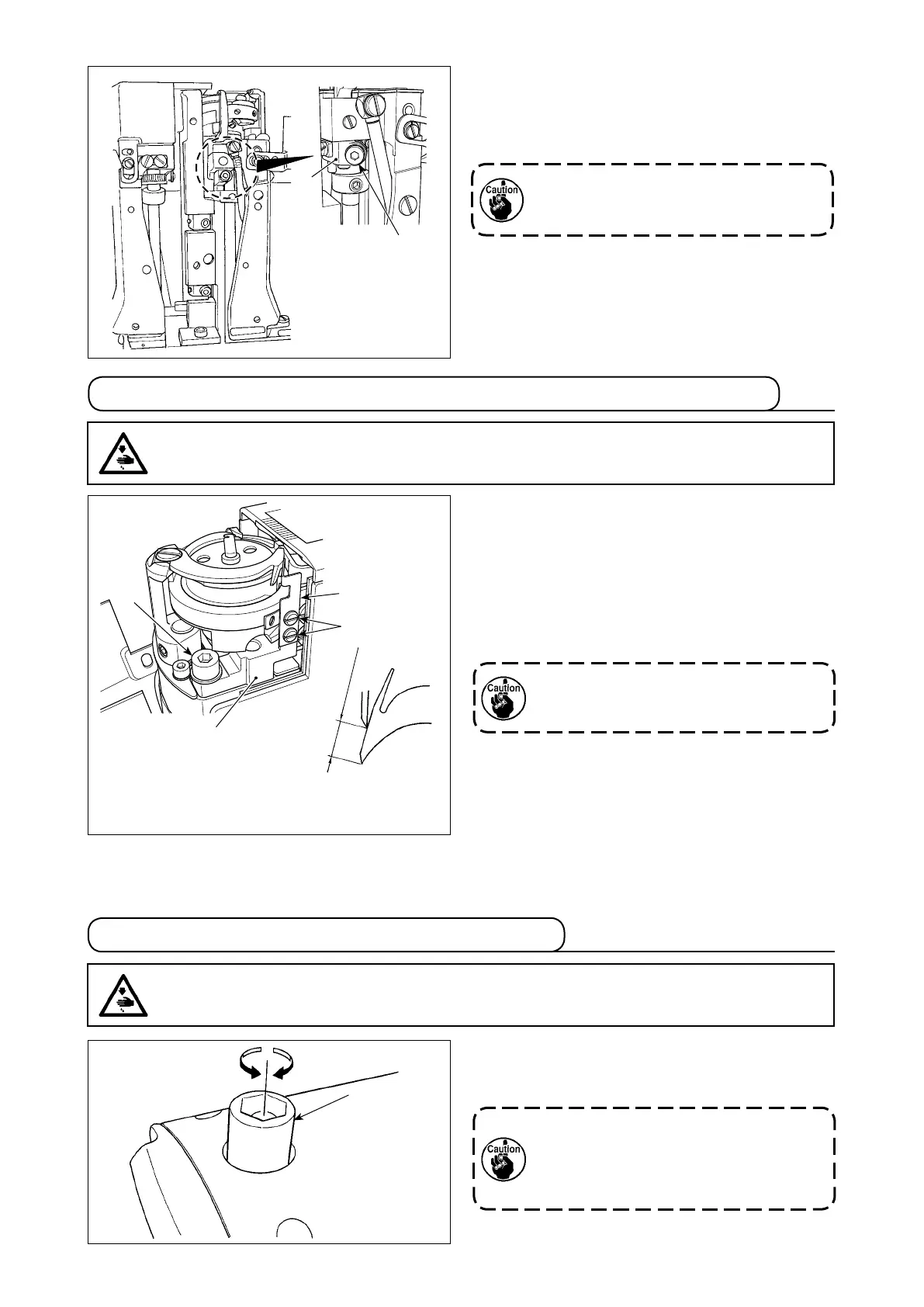

Turn presser spring regulating dial

clockwise

A

to

increase the pressure of the presser foot, or counter-

clockwise

B

to decrease it.

Be sure to operate the sewing machine

with the pressure of the presser foot

minimized as long as the presser foot

securely holds the material.

WARNING :

To protect against possible personal injury due to abrupt start of the machine, be sure to start the

following work after turning the power off and ascertaining that the motor is at rest.

4-8. Adjusting the pressure of the presser foot

B

A

5) Tighten setscrew

while pressing down bob-

bin case opening lever crank

.

6) Move inner hook guide

up and down to make

sure that there is not play in the thrust direction.

Loading...

Loading...