– 39 –

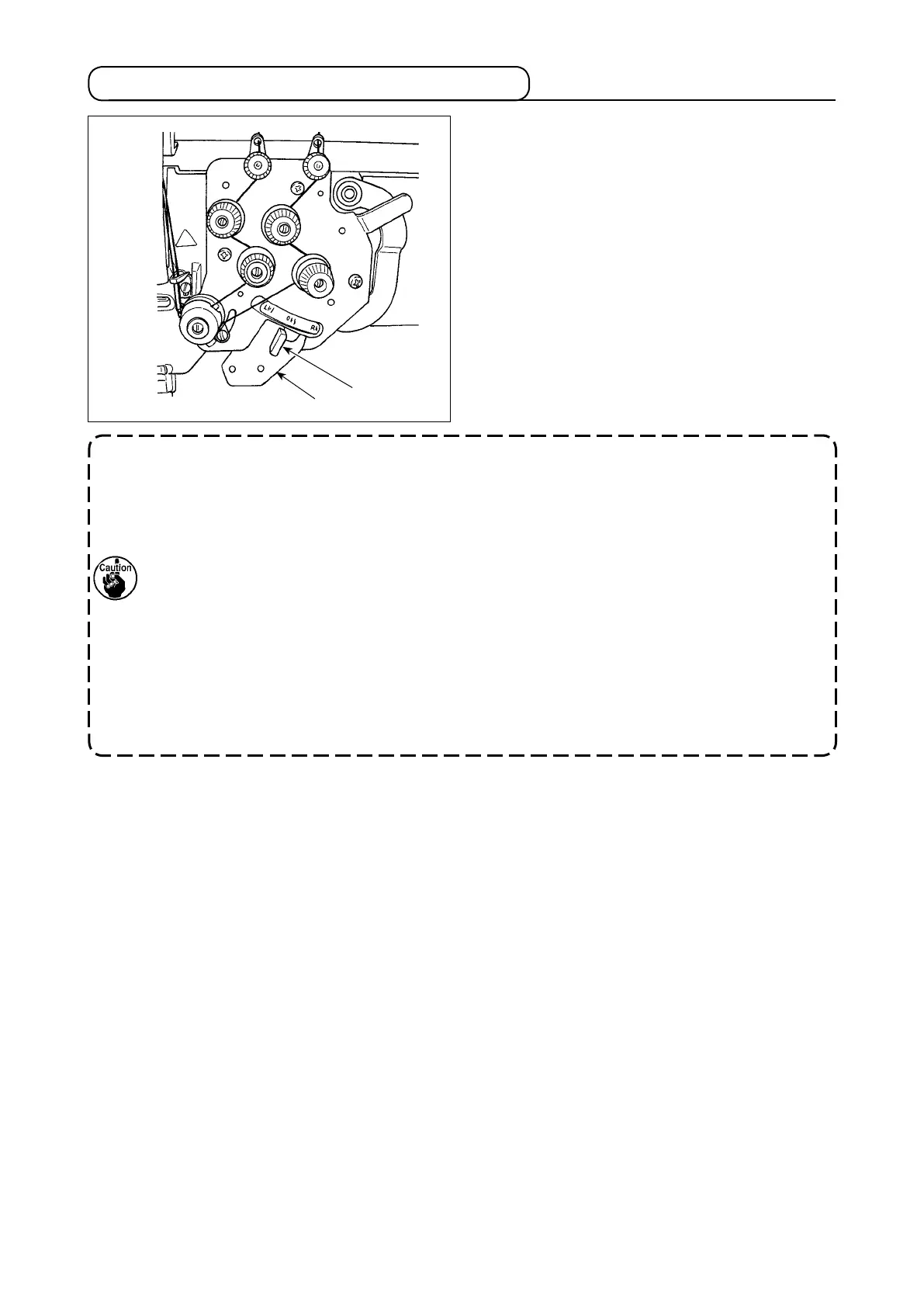

5-6. Organized split needle bar (PLC-2765)

(1) Stopping the needle bars (right and left)

When conversion lever

is moved to the L posi-

tion, the left needle bar stops. When the lever is

moved to the R position, the right needle bar stops.

(2) Returning to the 2-needle operation

Press conversion xing lever

.

Conversion lever

will move to 0 (zero) posi-

tion to restore the operation mode to the 2-nee-

dle sewing mode.

1. When sewing a corner of the material by turning it to the right or left, be aware that stitch

skipping occurs at the corner section if the needle bar goes up by 2 mm or more after it has

passed its lower end.

2. At the corner angle of which is 40 º or less, the thread may remain on the wrong side of the

material since the thread take-up amount of the bobbin thread slack prevention spring may be

insufcient.

3. When performing the operation of changeover of separately driven needle bar, perform the

work after stopping the sewing machine once.

When the operation of changeover is performed at 1,000 sti/min or more, break-down will be

caused.)

4. When the sewing machine is used as the substitute for 1-needle sewing machine in the state

of separately driven needle bar, break-down of the sewing machine will be caused. When per-

forming sewing with 1-needle sewing machine, remove one of two needles and use the sewing

machine in the state that two needle bars operate.

Loading...

Loading...