– 17 –

(1) Lubrication procedure

WARNING :

1. Do not connect the power plug until the lubrication has been completed so as to prevent

accidents due to abrupt start of the sewing machine.

2. To prevent the occurrence of an inammation or rash, immediately wash the related portions if

oil adheres to your eyes or other parts of your body.

3. If oil is mistakenly swallowed, diarrhea or vomitting may occur. Put oil in a place where children

cannot reach.

A

B

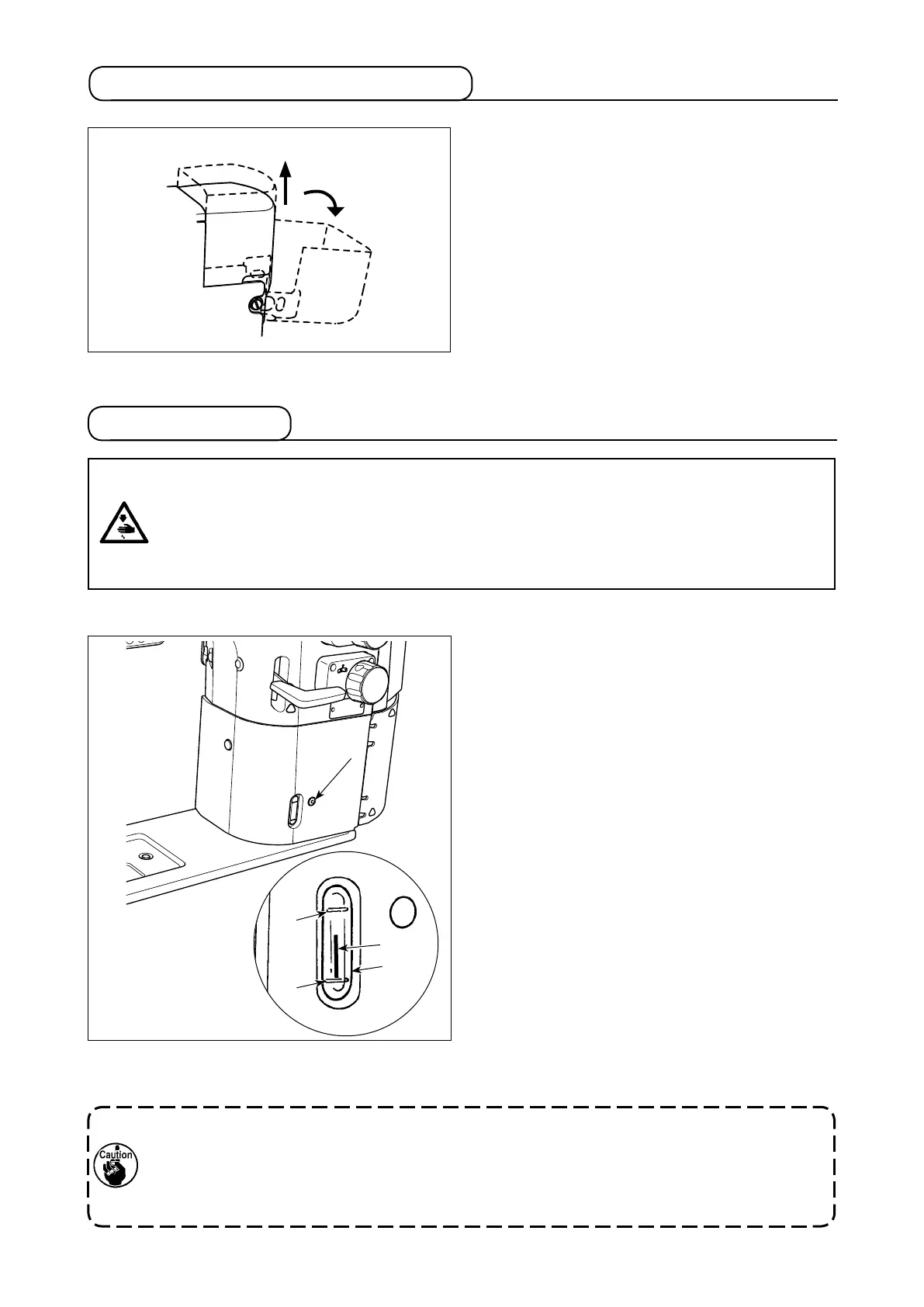

Move in the direction of B and open the hook cover

after lifting it in the direction of A once. In case of

2-needle machine, the same opening procedure is

taken for both left and right hooks.

3-4.

Opening/closing the hook cover

3-5. Lubrication

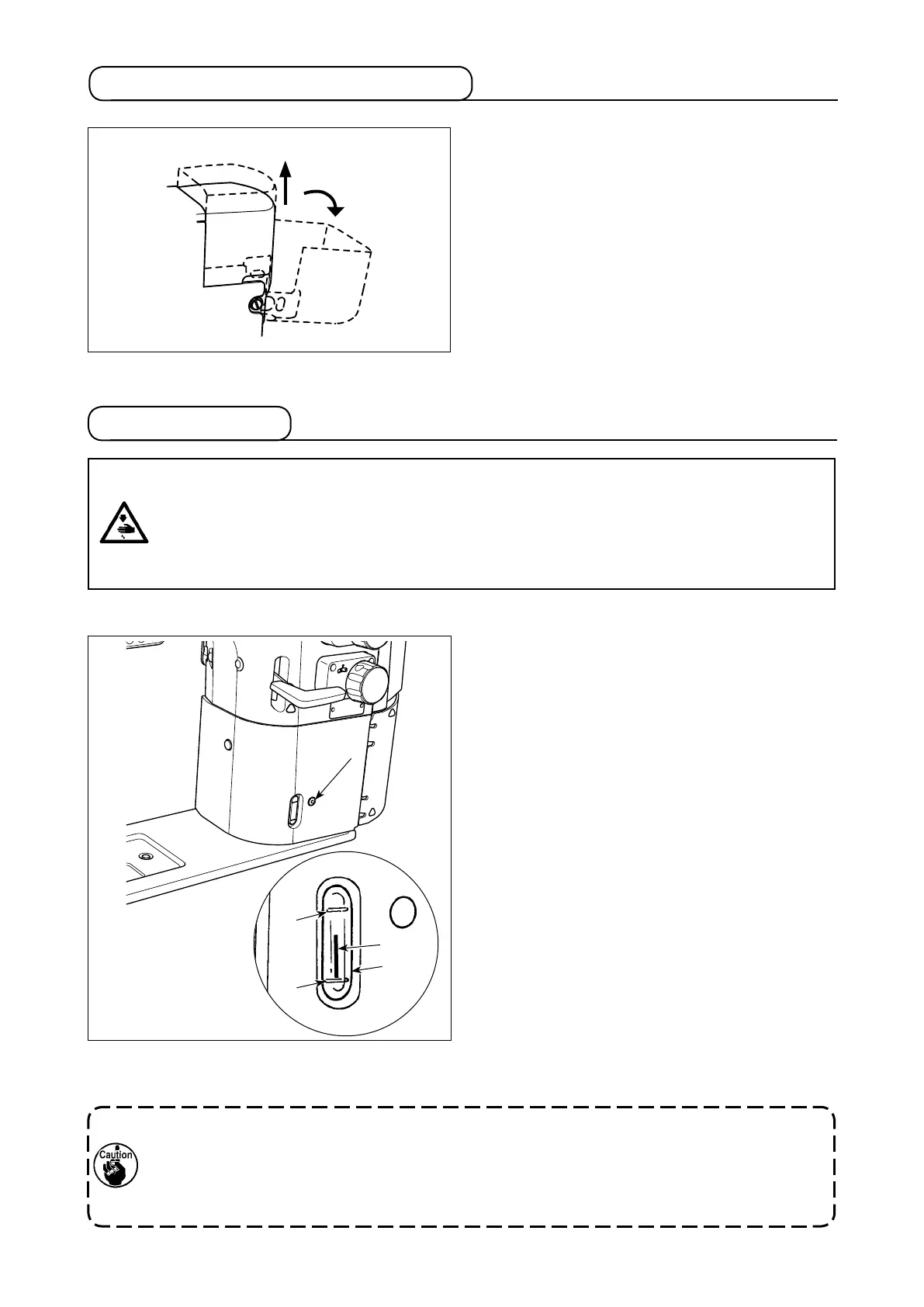

Fill the oil tank with oil for hook lubrication before op-

erating the sewing machine.

1) Fill the oil tank with JUKI NEW DEFRIX OIL No.1

(Part No. : MDFRX1600C0) or JUKI MACHINE

OIL No.7 (Part No. : MML007600CA) using the

oiler supplied with the machine from section .

2) Fill the oil tank with the oil until the top end of

oil amount indicating rod comes between the

upper engraved marker line and the lower

engraved marker line of oil amount indicating

window .

If the oil is lled excessively, it will leak from the

air vent hole in the oil tank or proper lubrication

will be not performed. In addition, when the oil is

vigorously lled, it may overow from the oil hole.

So, be careful.

3) When you operate the sewing machine, rell oil if

the top end of oil amount indicating rod comes

down to the lower engraved marker line of oil

amount indicating window .

1. When you use a new sewing machine or a sewing machine after an extended period of disuse,

use the sewing machine after performing break-in at 1,000 sti/min or less.

2. For the oil for hook lubrication, purchase JUKI NEW DEFRIX OIL No. 1 (Part No. : MDFRX1600C0)

or JUKI MACHINE OIL No.7 (Part No. : MML007600CA).

3. Be sure to lubricate clean oil.

Loading...

Loading...