Industrial Sewing Machine SADE

33

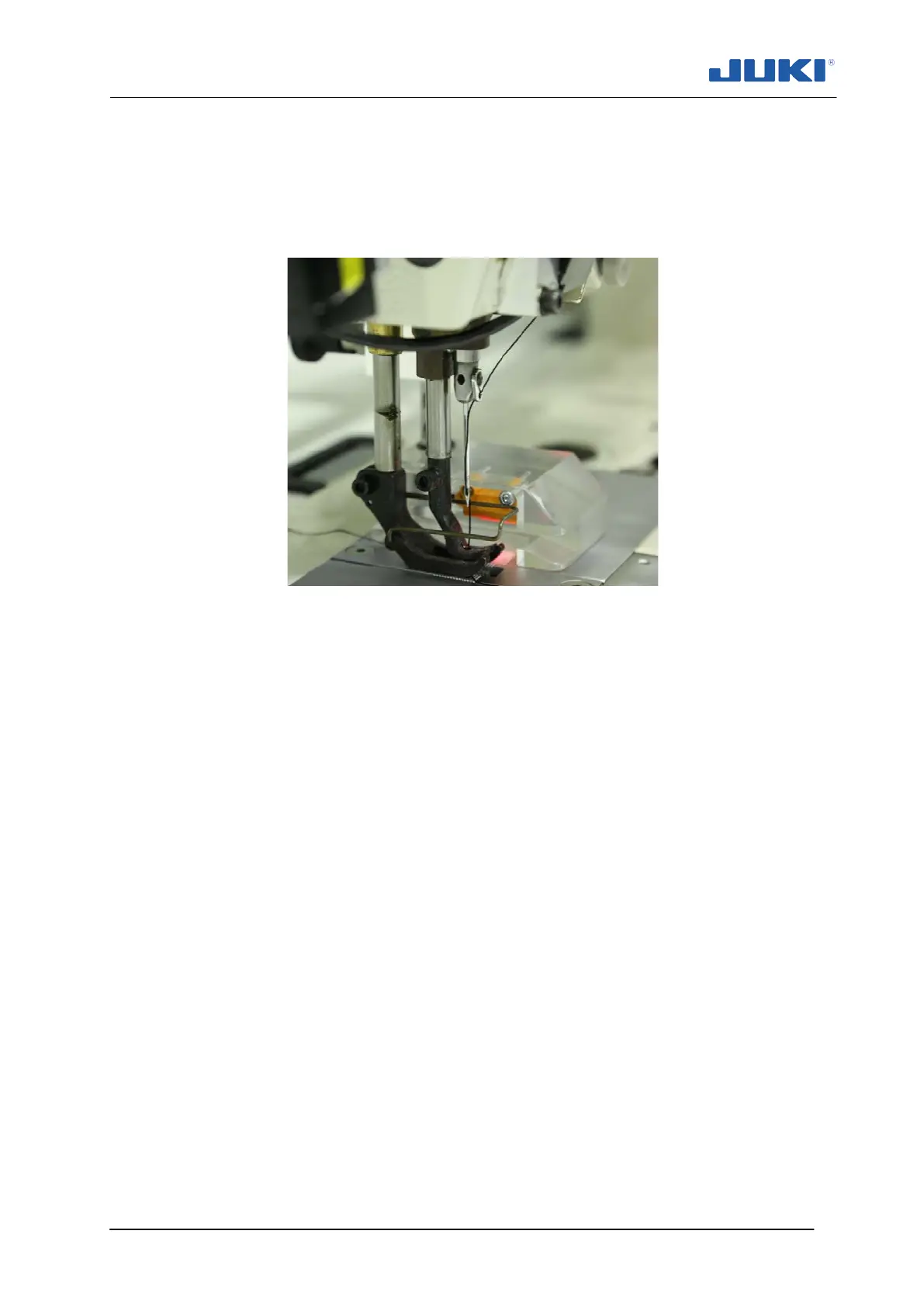

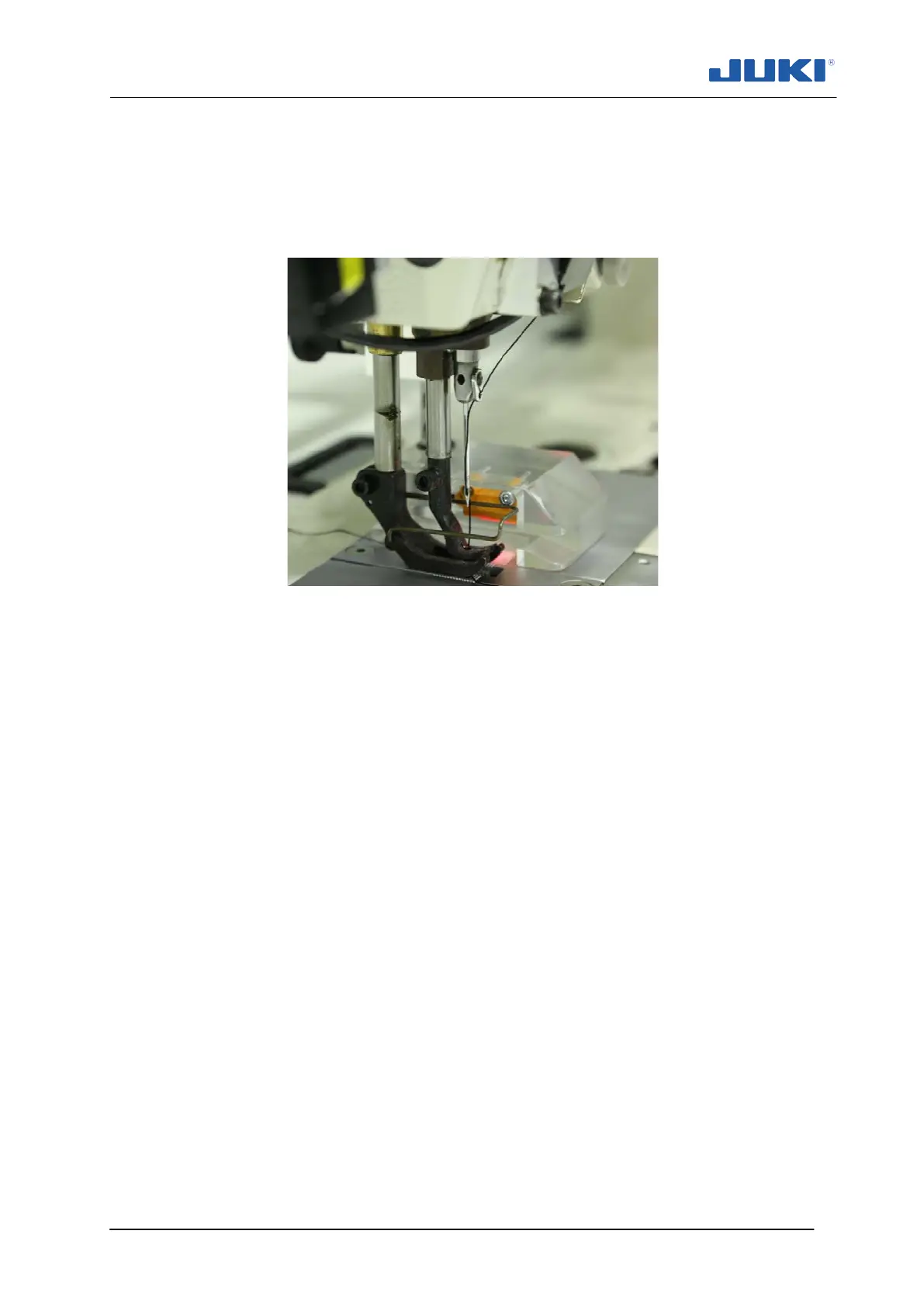

Swivel guide

Main function of the swivel guide is to support the operator in keeping seam to edge dis-

tance within tolerance. It can be adjusted sideways and upwards. An optical sensor de-

tects positive notches of the piece in order to trigger the start and end of the actual tear

seam area. The guide can be swivelled sideways and upwards to gain access to the

bobbin compartment.

Fig. 7. Swivel guide

Stitch length

The actual stitch length is considered to be critical for correct airbag deployment. At the

same time stitch length isn’t just the result of a certain dial setting. Material properties as

thickness and elasticity, presser foot adjustment and operator skills will affect the actual

stitch length. In Your machine version manual setting of the stitch length is not possible.

You can do this in the SADE software (see clause 7.1.2.13).

Bobbin winding station

The JUKI SADE uses a separate bobbin winding station instead of the sewing head in-

tegrated winder. Bobbins have a more consistent winding with a constant tension. The

bobbin thread cone is monitored by a barcode reader.

The bobbins of normal LU2810 sewing machines are incompatible with the bobbins

used on the JUKI SADE. This is done to avoid the accidental use of standard bobbins

with undetermined threads.

Loading...

Loading...