MAINTENANCE

1. With the power off, place the end of a flat-blade screw-

driver into the slot in the rear panel LINE FUSE holder.

Push in gently and rotate the fuse carrier one-quarter

turn counterclockwise. Release pressure on the holder

and its internal spring will push the fuse and carrier out

of the holder.

2. Remove the fuse and replace it with the type recom-

mended in Table 8-l.

CAUTION

Do not use a fuse with a higher current rating

than specified, or instrument damage may oc-

cur. If the instrument repeatedly blows fuses,

locate and correct the cause of the trouble

before replacing the fuse.

3. Install the new fuse and the fuse carrier into the holder

by reversing the above procedure.

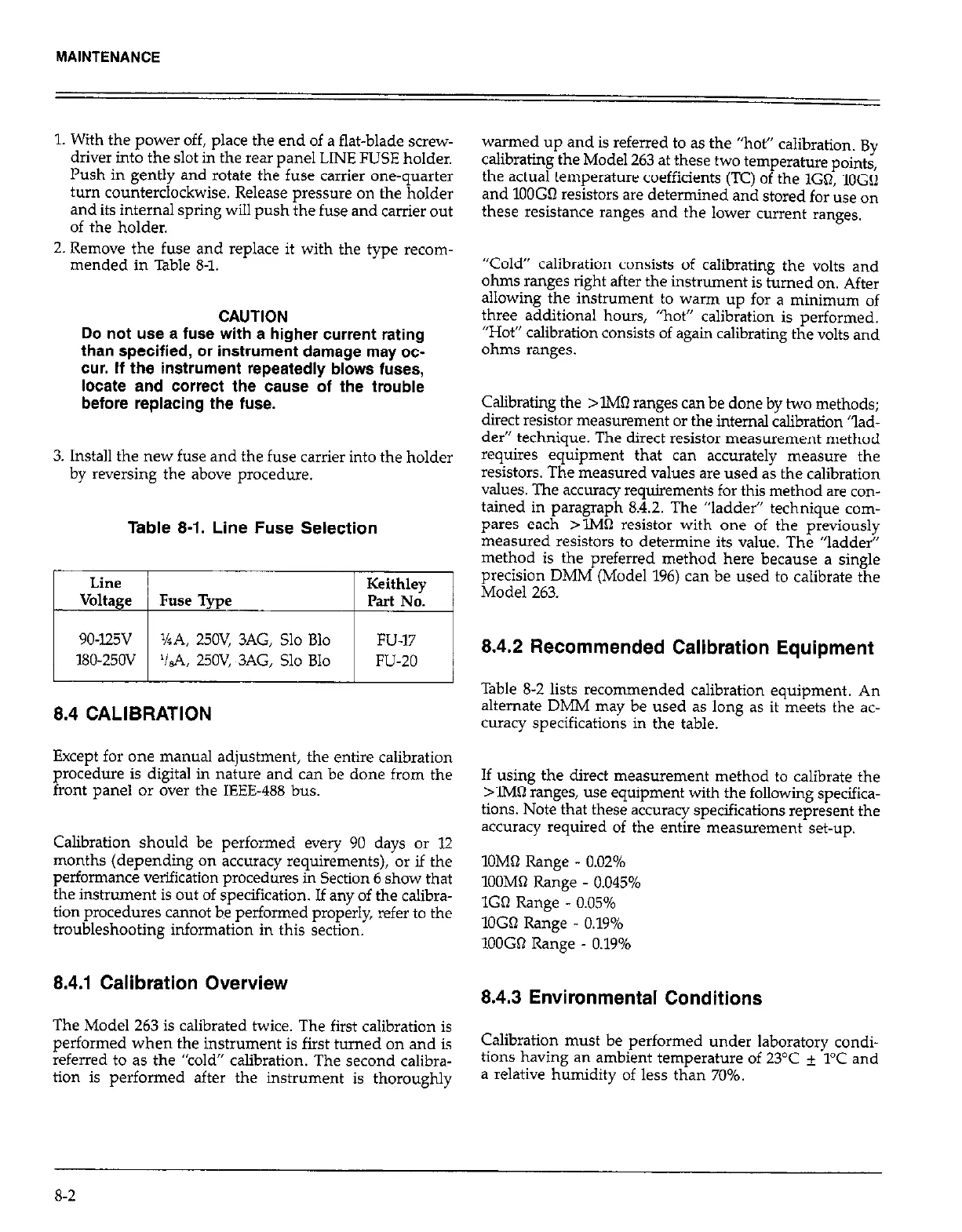

Table 8-l. Line Fuse Selection

Line Keithley

Voltage

Fuse Type

Part No.

I

I

90-l25v ‘/aA, 25OV, 3AG, Slo Blo FU-17

180-250V ‘isA, 25OV, 3AG, Slo Blo FU-20

8.4 CALIBRATION

Except for one manual adjustment, the entire calibration

procedure is digital in nature and can be done from the

front panel or over the IEEE-488 bus.

Calibration should be performed every 90 days or I2

months (depending on accuracy requirements), or if the

performance verification procedures in Section 6 show that

the instrument is out of specification. If any of the calibra-

tion procedures cannot be performed properly, refer to the

troubleshooting information in this section.

8.4.1 Calibration Overview

The Model 263 is calibrated twice. The first calibration is

performed when the instrument is first turned on and is

referred to as the “cold” calibration. The second calibra-

tion is performed after the instrument is thoroughly

warmed up and is referred to as the “hot” calibration. By

calibrating the Model 263 at these two temperature points,

the actual temperature coefficients (TC) of the lGQ, 1OGD

and lOOGO resistors are determined and stored for use on

these resistance ranges and the lower current ranges.

“Cold” calibration consists of calibrating the volts and

ohms ranges right after the instrument is turned on. After

allowing the instrument to warm up for a minimum of

three additional hours, “hot” calibration is performed.

“Hot” calibration consists of again calibrating the volts and

ohms ranges.

Calibrating the >lMQ ranges can be done by two methods;

direct resistor measurement or the internal calibration ‘lad-

der” technique. The direct resistor measurement method

requires equipment that can accurately measure the

resistors. The measured values are used as the calibration

values. The accuracy requirements for this method are con-

tained in paragraph 8.4.2. The “ladder” technique com-

pares each >lMfl resistor with one of the previously

measured resistors to determine its value. The “ladder”

method is the preferred method here because a single

precision DMM (Model 196) can be used to calibrate the

Model 263.

8.4.2 Recommended Calibration Equipment

Table 8-2 lists recommended calibration equipment. An

alternate DMM may be used as long as it meets the ac-

curacy specifications in the table.

If using the direct measurement method to calibrate the

>lMO ranges, use equipment with the following specifica-

tions. Note that these accuracy specifications represent the

accuracy required of the entire measurement set-up.

lOM0 Range - 0.02%

1OOMQ Range 0.045%

1GCl Range - 0.05%

lOGa Range - 0.19%

1OOGR Range - 0.19%

8.4.3 Environmental Conditions

Calibration must be performed under laboratory condi-

tions having an ambient temperature of 23’C + 1°C and

a relative humidity of less than 70%.

8-2

Loading...

Loading...