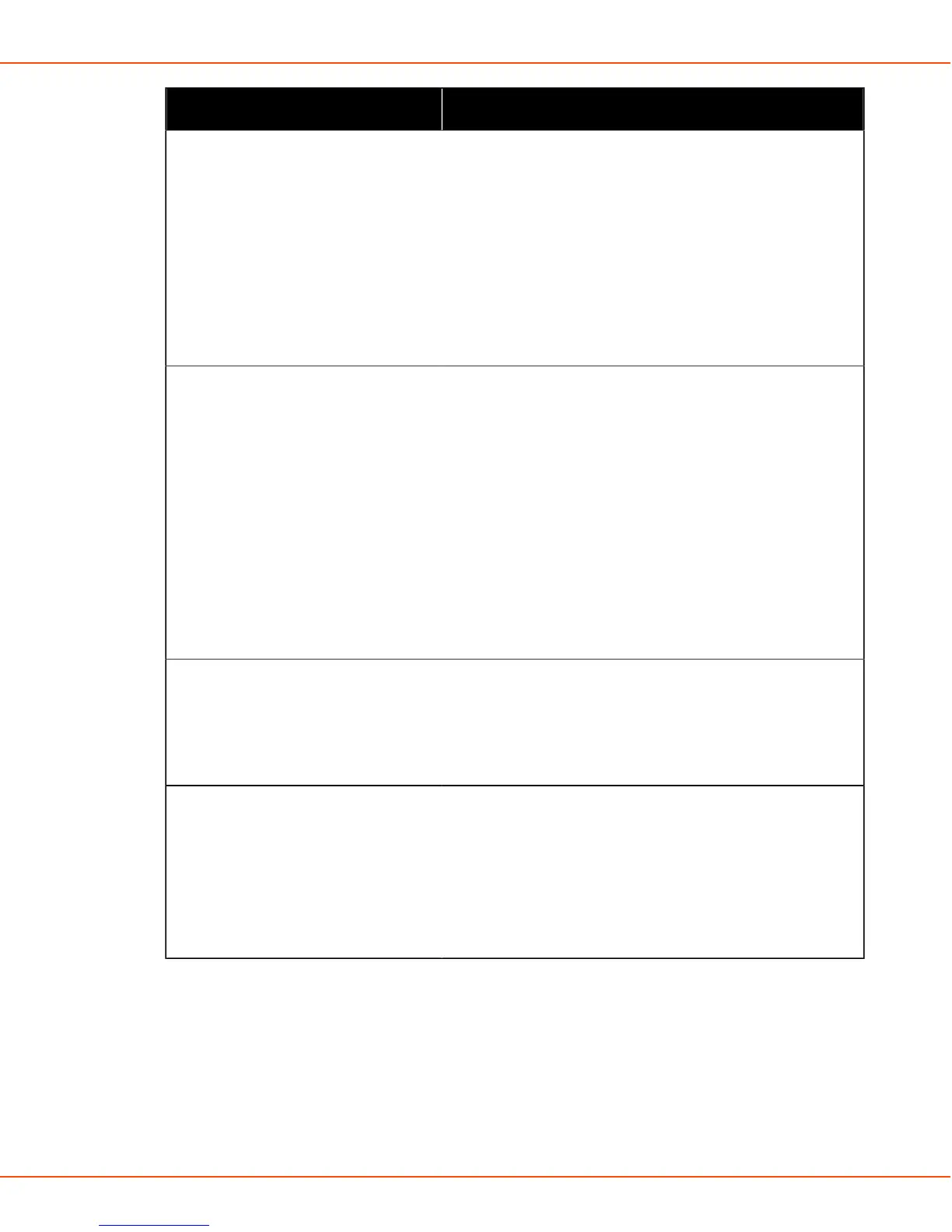

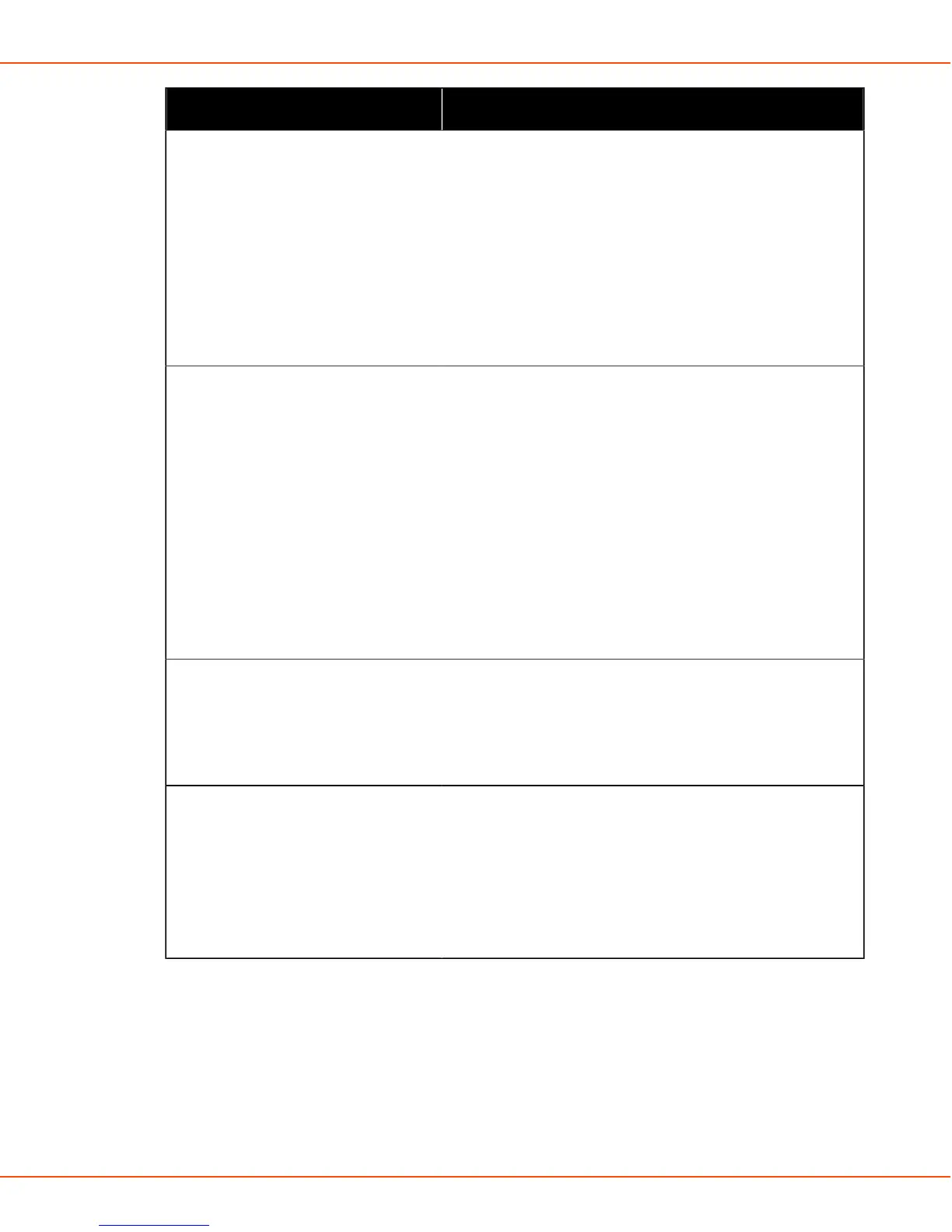

X8 MIG WELDER 2.6 Troubleshooting

Problem Recommended actions

The wire burns into the contact tip

• Make sure the size and type of the current tip and

wire liner are suitable for the filler wire.

• Make sure the wire liner is clean.

• Make sure the wire liner does not make any steep

loops.

• Check the motor current level. If the current is too

high, there may be problems in the wire liner.

• Check the tightness of the feeding rolls. Too tight

feeding rolls may affect soft filler wires, such as

aluminium and flux-cored wires.

The gun overheats

• Make sure the coolant circulation is working

normally (see the coolant circulation warning LED

in the power source).

• Measure the coolant circulation speed: detach the

coolant output hose from the wire feeder while the

power source is on, and let the coolant run into a

measurement cup. The circulation must be at least

0.5 l/min.

• Make sure that the welding parameters are within

the range of the welding gun and the neck.

The gun and the neck have separate limits for

the maximum current; the lower of these is the

maximum current that can be used.

The welding gun connector

overheats

• Make sure the connector is properly connected to

the wire feeder.

• Make sure the current transfer surface and the

connector pins of the gun connector are clean and

undamaged.

The gun vibrates too much during

welding

• Check the tightness of the contact tip adapter and

contact tip.

• Check the motor current.

• Check the wire liner.

• Check the filler wire. It must be straight and start

coiling when it comes out from the contact tip. If

not, check the tightness of the feeding rolls.

OPERATING MANUAL | EN 158

©

KEMPPI 2017 | 1817

Loading...

Loading...