X8 MIG WELDER 2.7 Maintenance

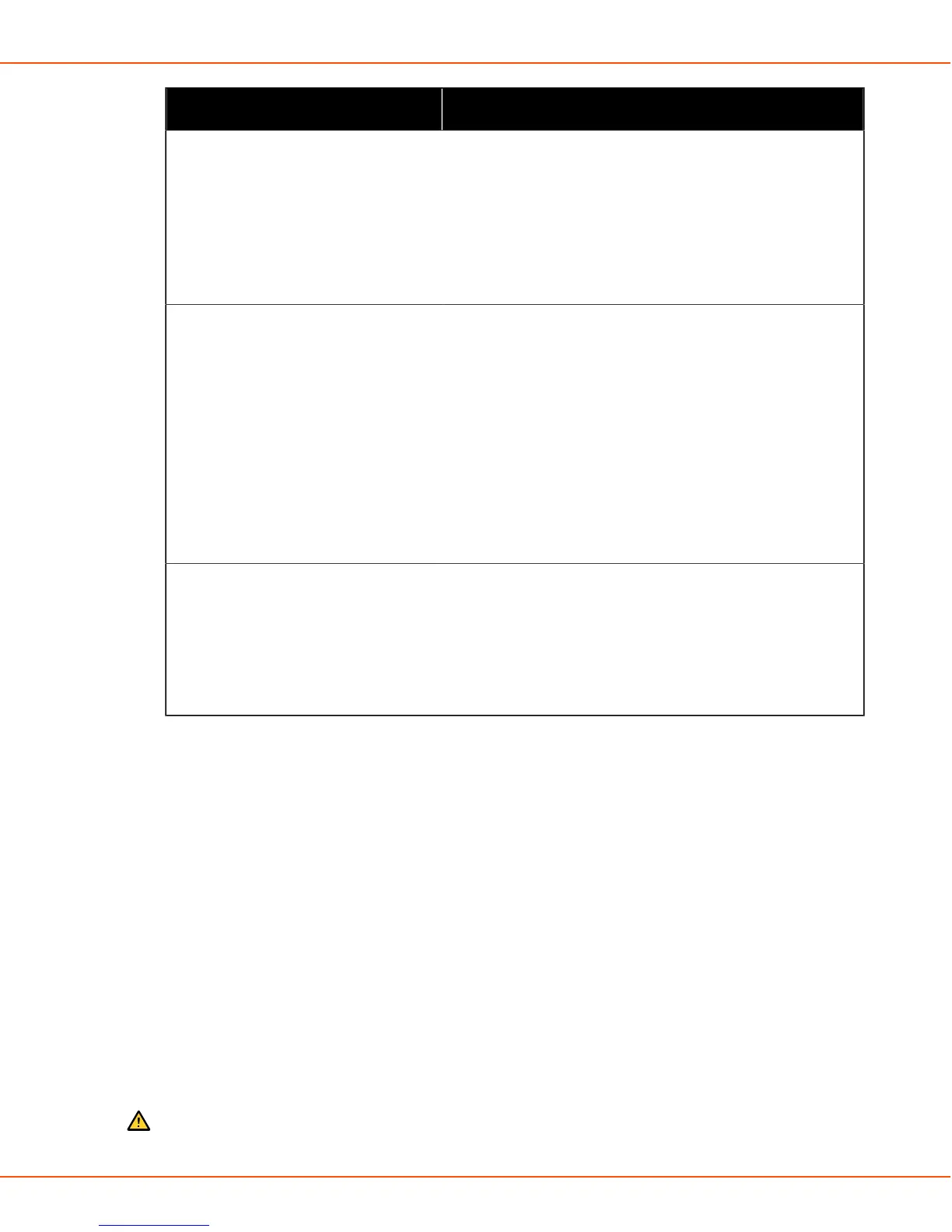

Problem Recommended actions

Dirty and/or poor quality weld

• Check that the shielding gas has not run out.

• Check that the shielding gas flow is unobstructed.

• Check that the gas type is correct for the

application.

• Check the polarity of the gun/electrode.

• Check that the welding procedure is correct for the

application.

Varying welding performance

• Check that the wire feed mechanism is adjusted

properly.

• Blow compressed air through the wire liner to

check that it is not blocked.

• Check that the wire liner is correct for the selected

wire size and type.

• Check the welding gun contact tip's size, type and

wear.

• Check that the welding gun is not overheating.

• Check that the earth return clamp is properly

attached to a clean surface of the workpiece.

High spatter volume

• Check the welding parameter values and welding

procedure.

• Check the gas type and flow.

• Check the polarity of the gun/electrode.

• Check that the filler wire is correct for the current

application.

2.6.1 Error codes

In error situations, Control Pad displays the number and title of the error, a description of the

possible cause (Reasons) and the Actions to fix the error. Go to View> Error log to see the error

history.

The wire feeder control panel displays the number and title of the error.

2.7 Maintenance

When considering and planning routine maintenance, consider the operating frequency of the

welding system and the working environment.

Correct operating of the welding machine and regular maintenance helps you avoid unnecessary

downtime and equipment failure.

2.7.1 Daily maintenance

Caution:

OPERATING MANUAL | EN 159

©

KEMPPI 2017 | 1817

Loading...

Loading...