X8 MIG WELDER 2.7 Maintenance

Disconnect the power source from the mains before handling electrical cables.

Maintenance of power source and wire feeder

Follow these maintenance procedures to maintain the proper functioning of the welding system:

• Check that all covers and components are intact.

• Check all the cables and connectors. Do not use them if they are damaged and contact service

for replacements.

• Check the wire feeder's feed rolls and the pressure handle. Clean and lubricate with a small

quantity of light machine oil, if needed.

Maintenance of guns

• Check regularly that all the components are tightly fastened.

• Check that the current transfer surface on the Kemppi gun adapter is clean and

unscratched, and the connector pins are straight and undamaged.

• Check the protective hose on the cable for damage.

• Check the two O-rings between the neck and the handle for wear and damage.

Note:

Only the gas-cooled gun has the O-rings.

• Clean dust from the liner with pressurized air every time you change the wire spool, or every

day during heavy use.

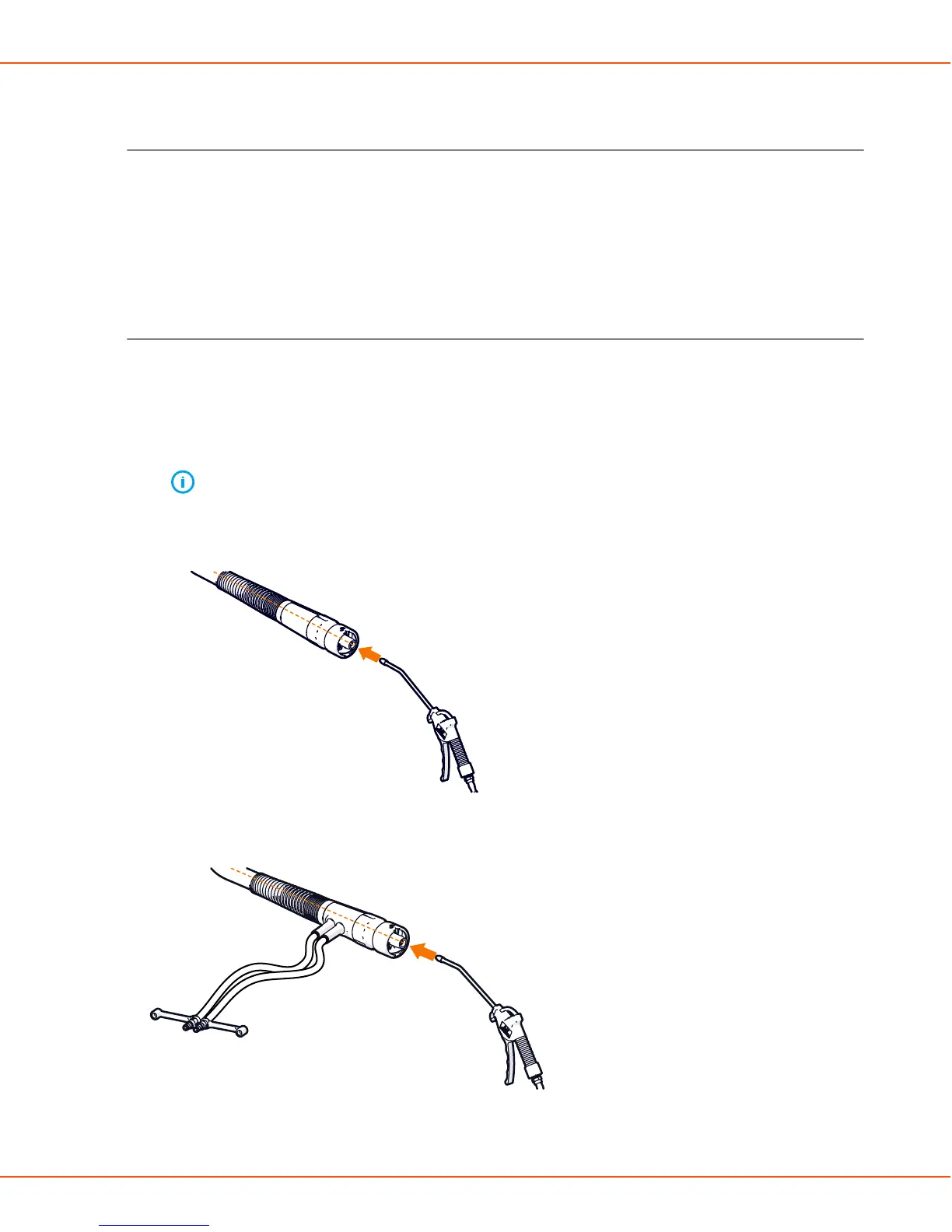

Figure 48: Gas-cooled gun

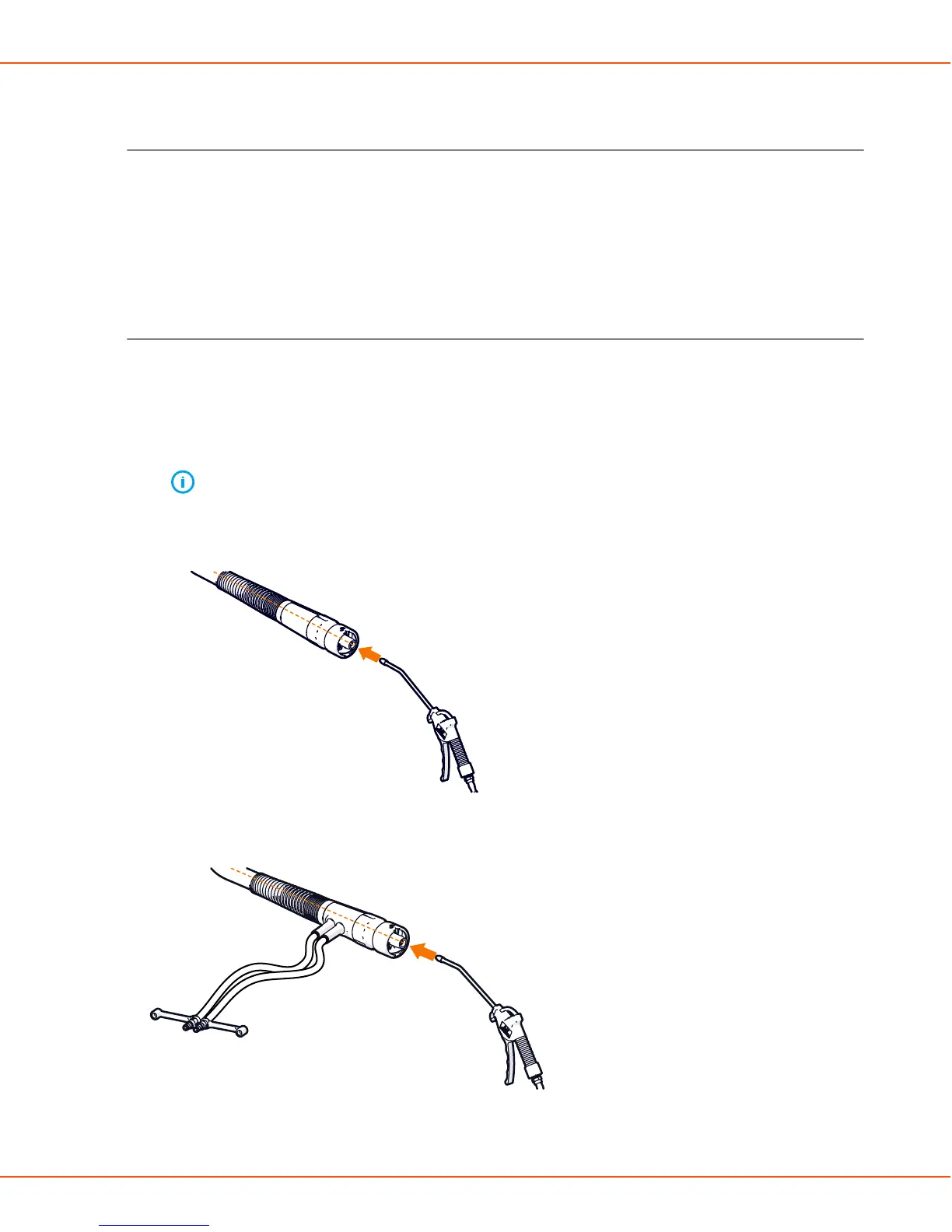

Figure 49: Water-cooled gun

OPERATING MANUAL | EN 160

©

KEMPPI 2017 | 1817

Loading...

Loading...