5-1

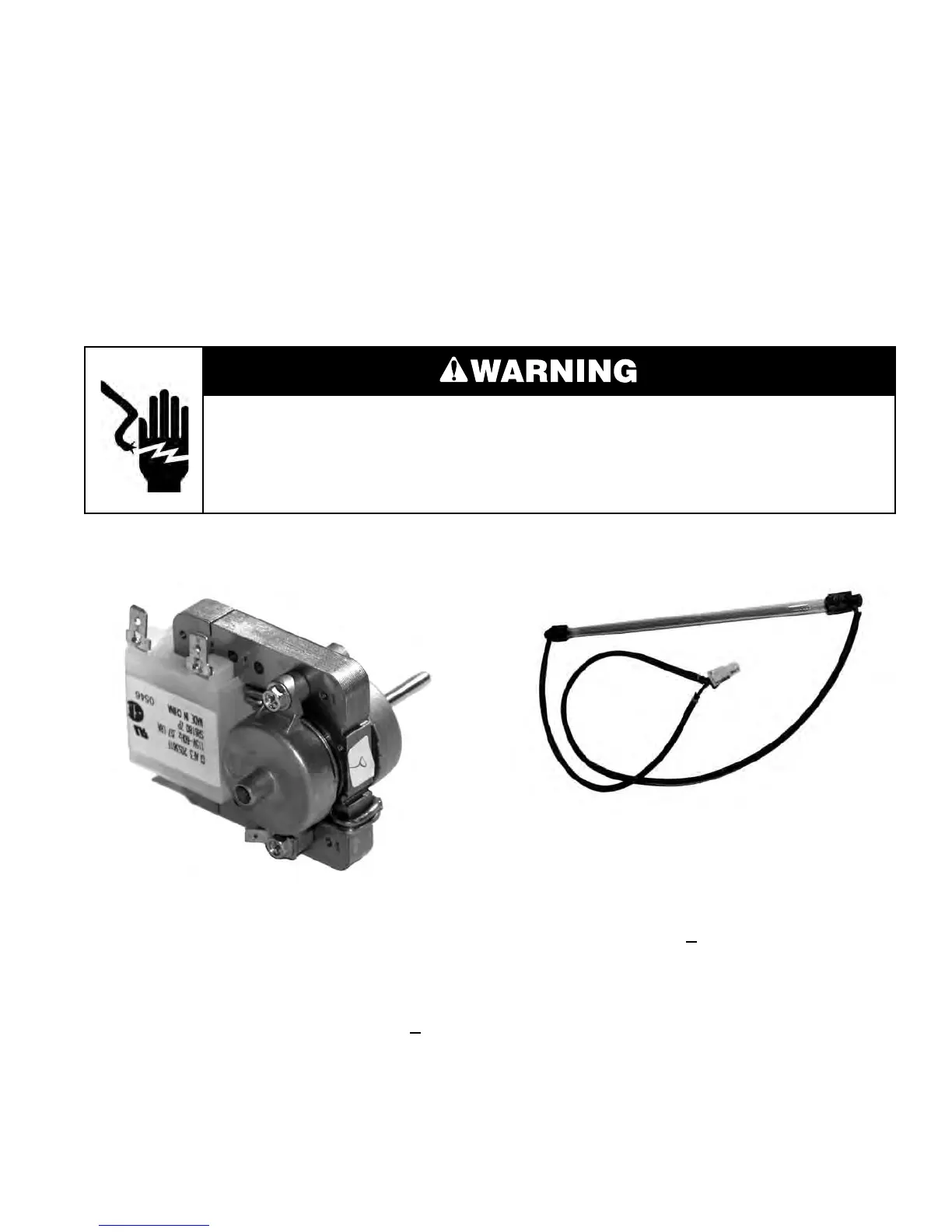

See Page 4-5 for access and removal proce-

dures for the evaporator fan and motor.

Touch the leads of an ohmmeter to the termi-

nals of the evaporator fan motor.

The meter should indicate 150 ohms + 10%

1.

2.

3.

Check all connections before replacing com-

ponents, looking for broken or loose wires,

failed terminals, or wires not pressed into

connectors far enough.

Resistance checks must be made with pow-

er cord unplugged from outlet, and with wir-

ing harness or connectors disconnected.

•

•

COMPONENT TESTING

Before testing any of the components, perform

the following checks:

The most common cause for control failure

is corrosion on connectors. Therefore, dis-

connecting and reconnecting wires will be

necessary throughout test procedures.

All tests/checks should be made with a VOM

or DVM having a sensitivity of 20,000 ohms-

per-volt DC, or greater.

•

•

EVAPORATOR FAN MOTOR

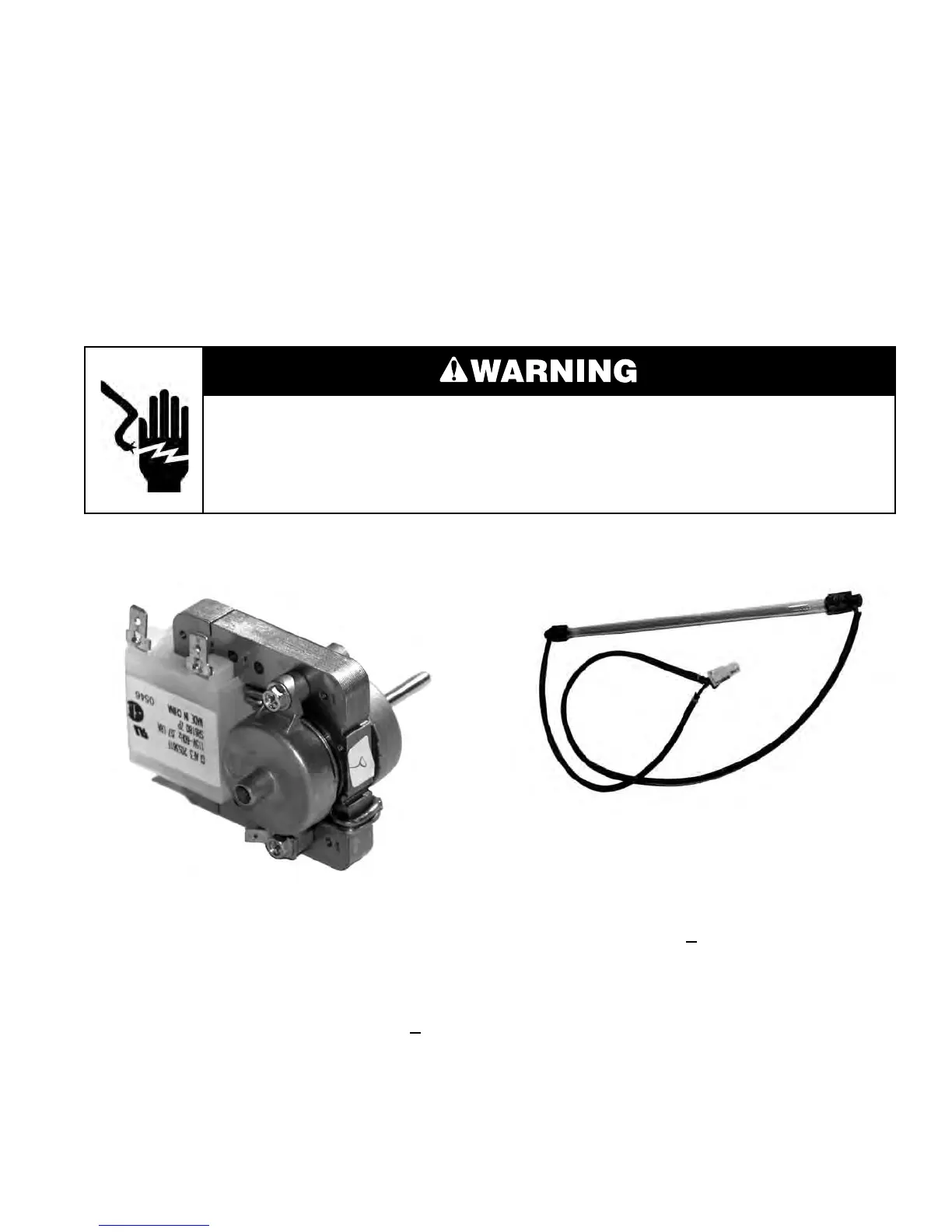

See Page 4-10 for access and removal pro-

cedures for the Defrost heater.

Touch the leads of an ohmmeter to the termi-

nals of the Defrost Heater. The meter should

indicate 150 ohms + 10%

1.

2.

DEFROST HEATER

Electrical Shock Hazard

Disconnect power before servicing.

Replace all parts and panels before operating.

Failure to do so can result in death or electrical shock.

Loading...

Loading...