Service ManualService Manual

Operating Lights marLEDOperating Lights marLED

®®

E9 / E9i / E15E9 / E9i / E15

VV 1 01 0 8585

c) Checking the locking screwc) Checking the locking screw

•• Check locking screws (3 or 2) for presence, correct length and snug seat:Check locking screws (3 or 2) for presence, correct length and snug seat:

—— AC2000: M4x5 oval head screw acc. to DIN 7985, without washerAC2000: M4x5 oval head screw acc. to DIN 7985, without washer

••

√√

d) Checking the nose segmentd) Checking the nose segment

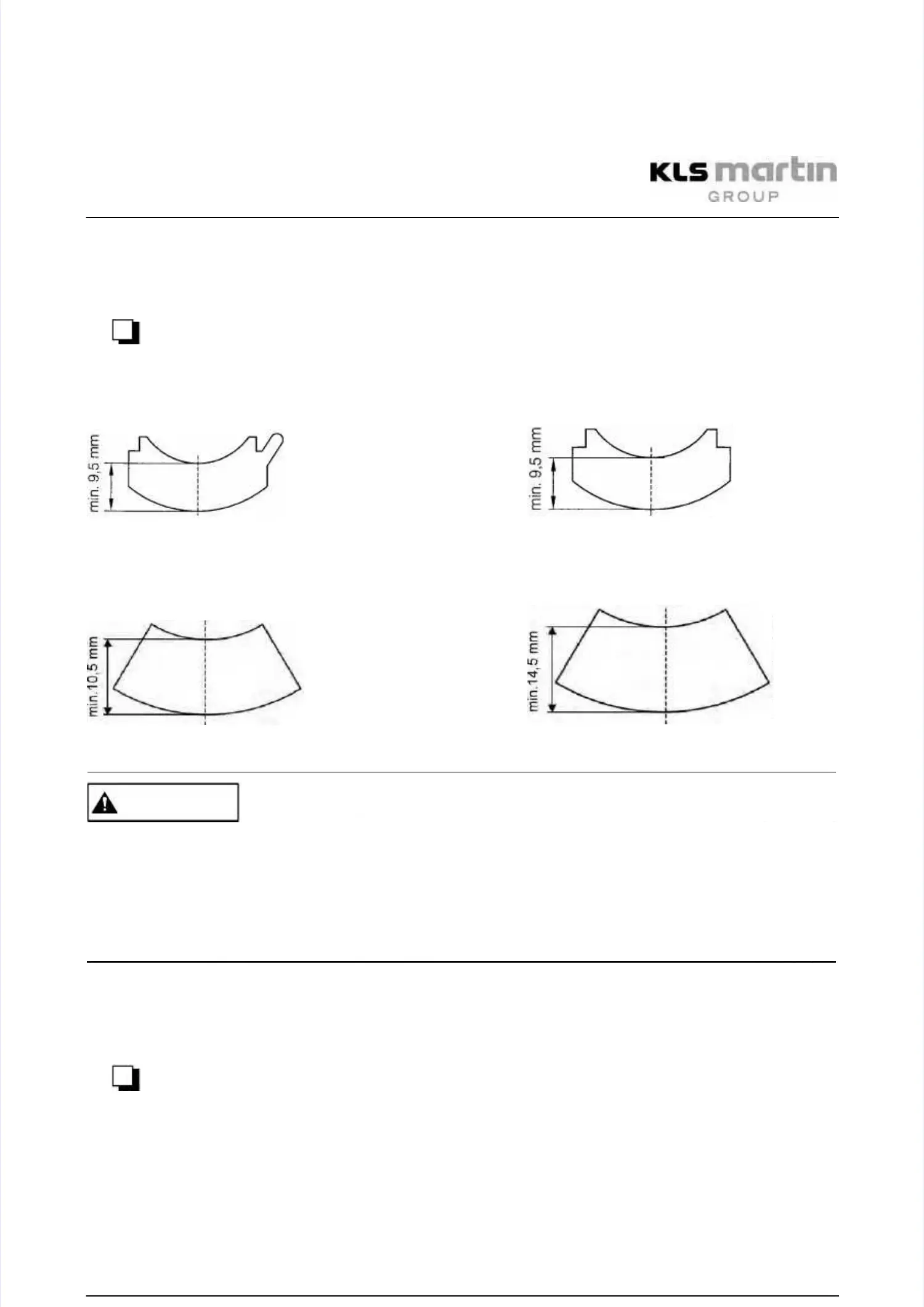

Fig. Fig. 10-10 10-10 AC2000 AC2000 nose nose segment segment (until (until June June 2006) 2006) AC1400 AC1400 / / AC2000 AC2000 (from (from June June 2006)2006)

••

Verify that the engaging part of the securing nose segment has a minimum thickness ofVerify that the engaging part of the securing nose segment has a minimum thickness of

1.5 mm in the case of AC1400 / AC2000 spring arms. Replace nose segment if necessary.1.5 mm in the case of AC1400 / AC2000 spring arms. Replace nose segment if necessary.

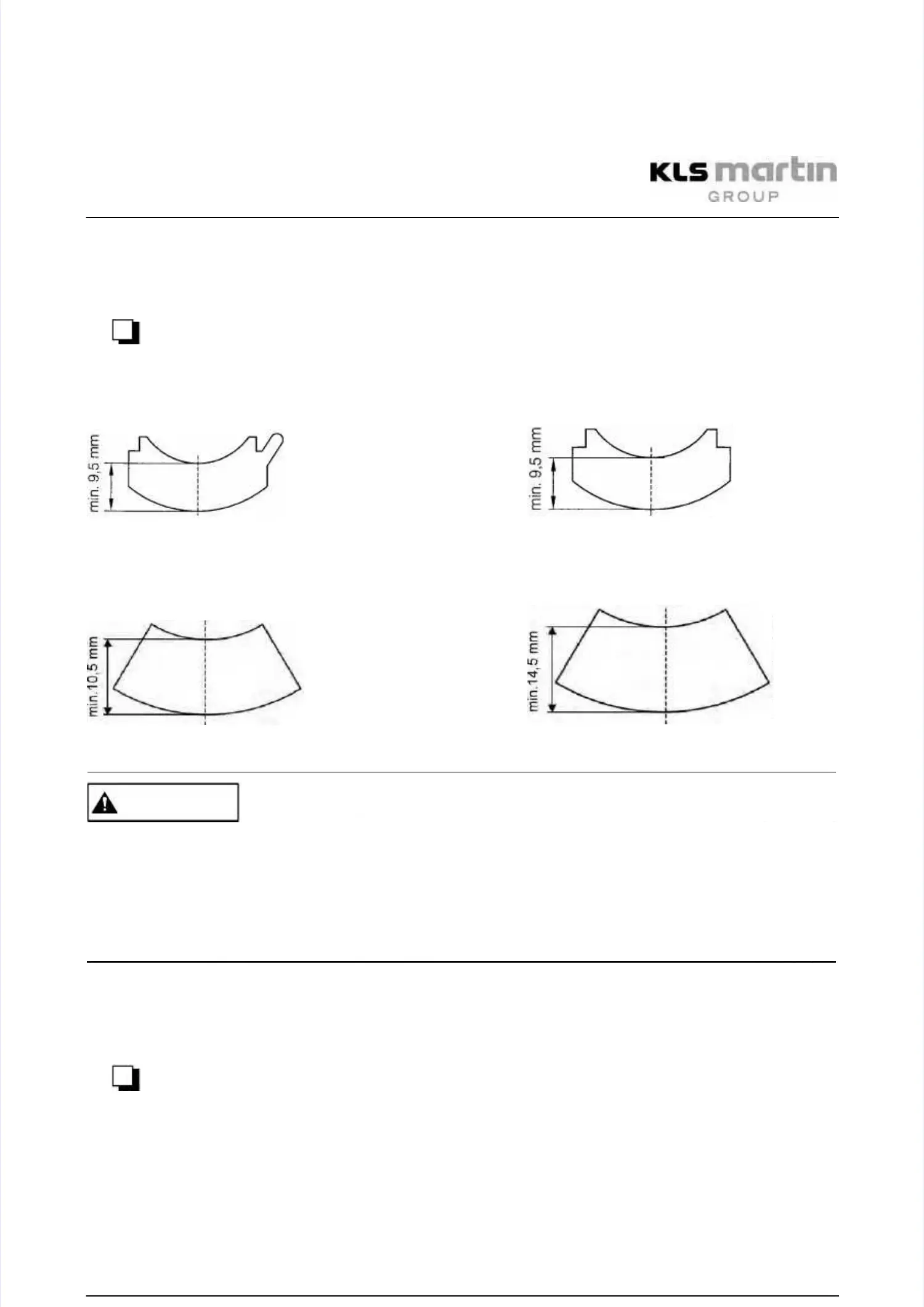

Fig. Fig. 10-11 AC3000 10-11 AC3000 nose nose segment segment Onda Onda SpaceSpace

Danger of injury or material damage!Danger of injury or material damage!

The AC3000 and Onda Space (OSP) spring arms usually have through-cabling and lack aThe AC3000 and Onda Space (OSP) spring arms usually have through-cabling and lack a

redundant locking screw. In this case, it is only possible to check the securing nose segmentredundant locking screw. In this case, it is only possible to check the securing nose segment

when working with an assistant capable of holding the suspended load or the spring arm neckwhen working with an assistant capable of holding the suspended load or the spring arm neck

in the given position!in the given position!

••

Verify that the engaging part of the nose segment has a minimum thickness of 1.5 mmVerify that the engaging part of the nose segment has a minimum thickness of 1.5 mm

(AC3000) or 3.5 mm (Onda Space). Replace nose segment if necessary.(AC3000) or 3.5 mm (Onda Space). Replace nose segment if necessary.

••

Grease the nose segment (e.g. with Molycote MOS 2).Grease the nose segment (e.g. with Molycote MOS 2).

••

√√

CAUTIONCAUTION

Loading...

Loading...