Section 9

Troubleshooting

20425626

5-2005/Rev 0

9-7

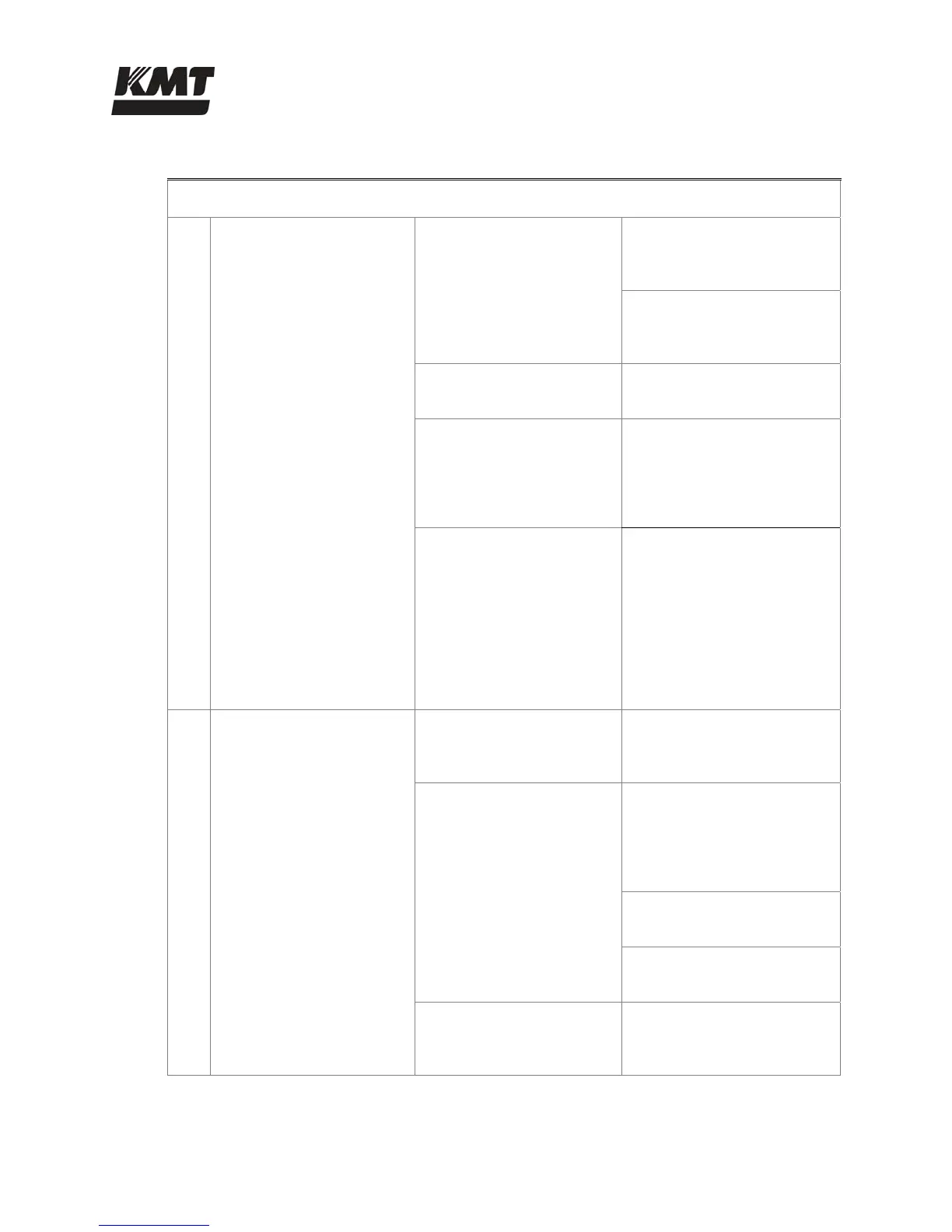

S30 Troubleshooting Guide

Malfunction Indication Comments

Make sure the gland nut is

tightened to the proper torque

specification.

Seat in the discharge check

valve is not sealing properly

Inspect the seat, sealing head

and gland nut for scratches,

erosion or cracks.

Improper torque on gland nut Tighten the gland nut to the

proper torque specification.

Erosion or scratches on the

contact surface of the sealing

head, or on the gland nut

where the seat makes contact

Polish the surfaces following

the procedure, Sealing Head

Maintenance, detailed in

Section 8, High Pressure Water

System.

15.

Water leaking from the weep

hole in the sealing head

Internal crack in sealing head Replace the sealing head.

A cracked sealing head can

result in water leaking from the

high pressure outlet passage to

the low pressure inlet passages.

The sealing head body can

become extremely hot.

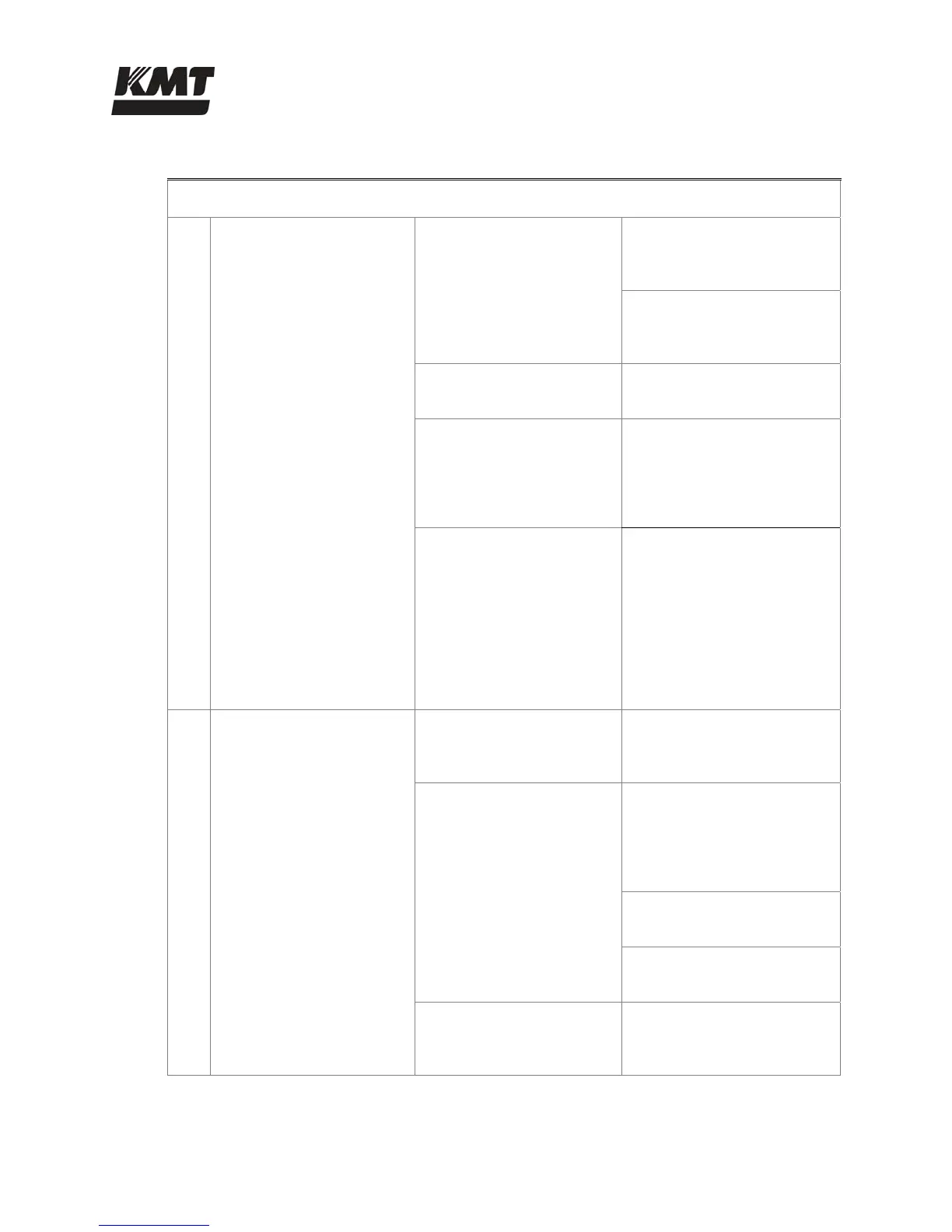

High pressure piping gland

nut is not tight and is not

sealing properly

Tighten the gland nut to the

proper torque specification.

Check the number of exposed

threads past the collar on the

high pressure piping. Only 1-

1/2 to 2-1/2 threads should be

exposed.

Check high pressure piping for

damage, cracks or deformation.

Improper high pressure piping

connection

Inspect the gland nut for

deformation of the threads.

16.

Water leaking from the weep

hole in the sealing head gland

nut

Damaged sealing head gland

nut

Check the gland nut for cracks

due to fatigue. If cracks are

detected, replace the gland nut.

Loading...

Loading...