SECTION 7

HIGH PRESSURE WATER

p. 7-20

80078868

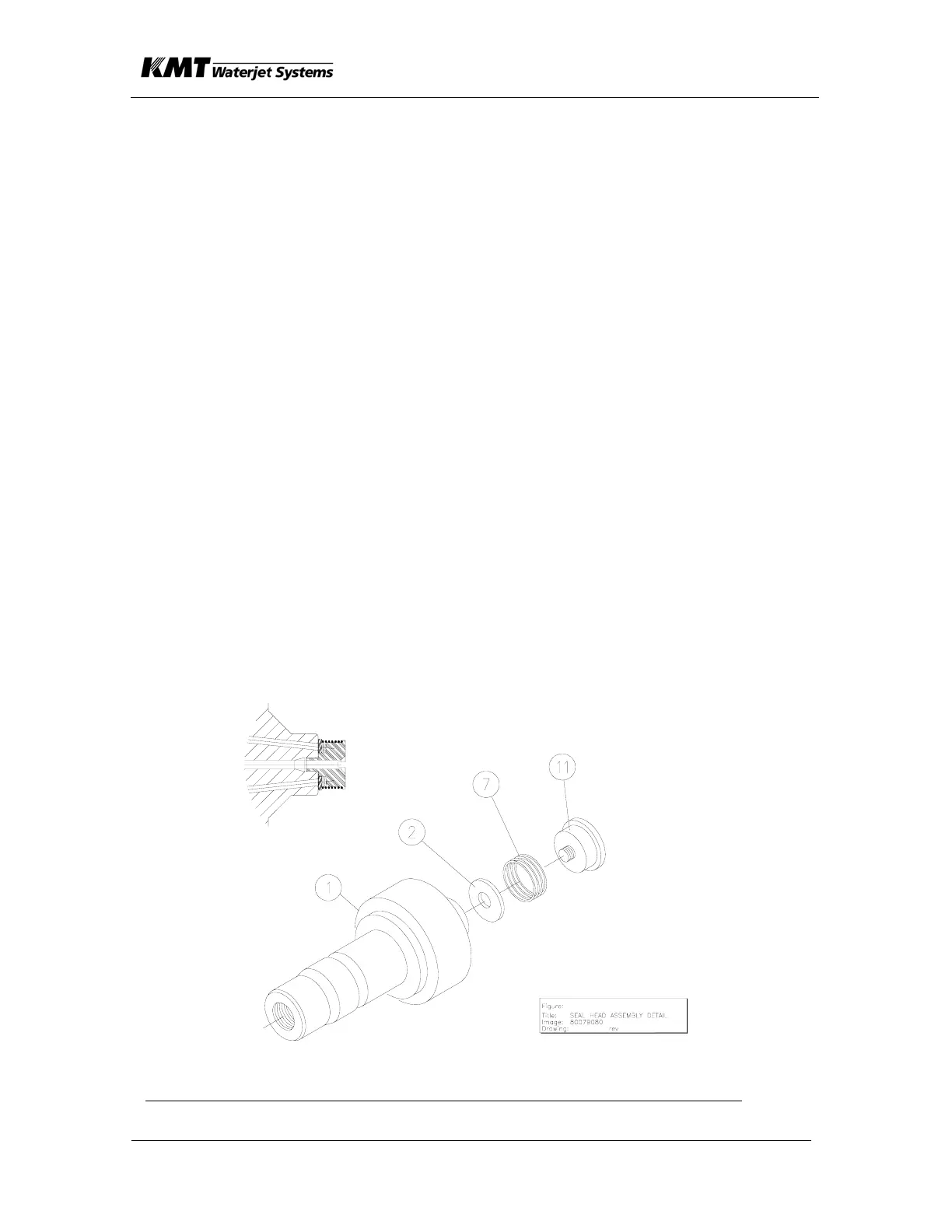

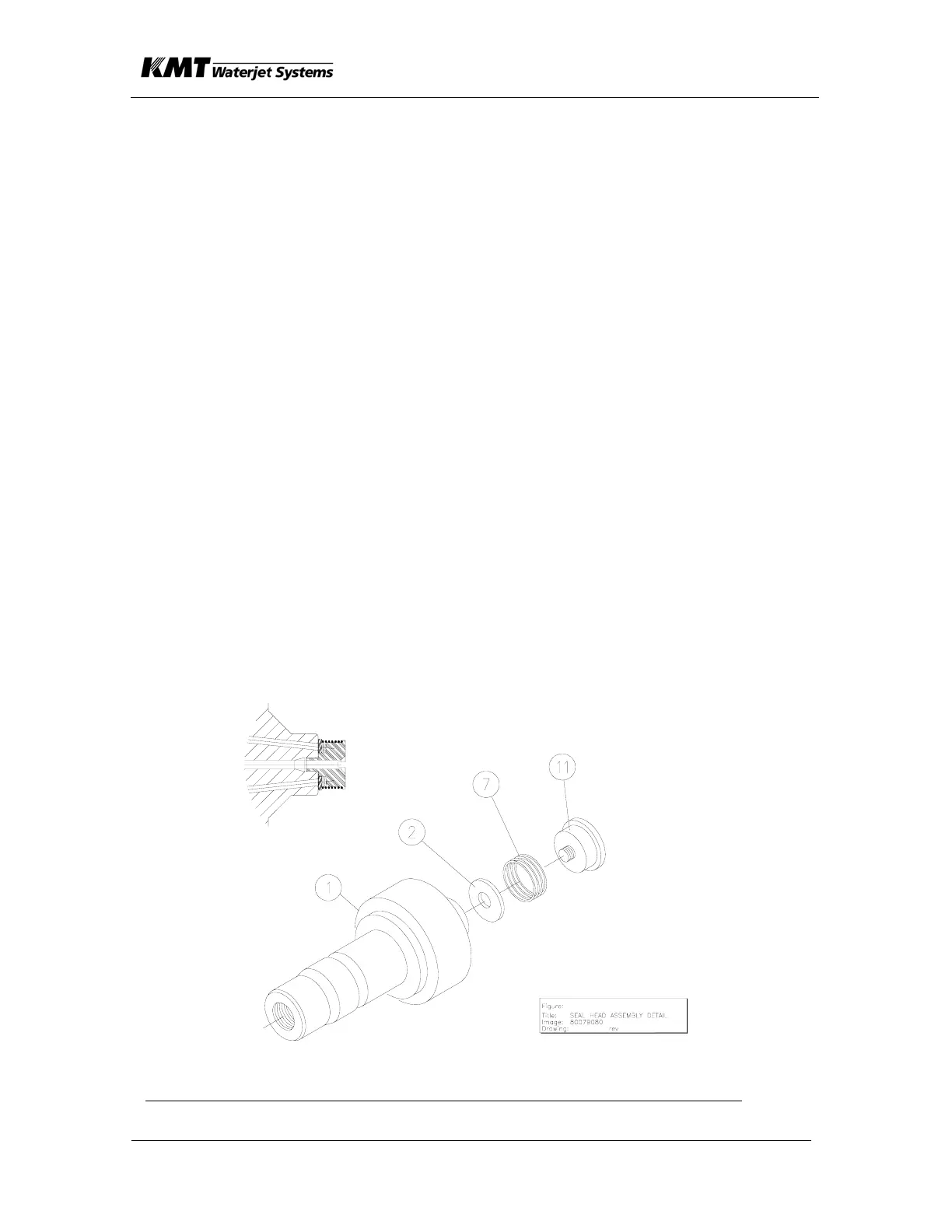

7.3.2 Inlet Check Valve

1. Use a ½” flat bladed screwdriver to unscrew the poppet retainer from

the sealing head. The inlet check valve is disassembled.

2. Inspect and refinish the sealing head face seal surface per instructions in

Section 7.3.3.

3. Inspect both surfaces of the flat washer shaped poppet. If one surface is

marred, and the opposite surface is not, the poppet may be reversed

with the best surface facing the sealing head. If both sides are worn,

replace poppet.

4. Assemble poppet (2) and spring (7) on poppet retainer (11). Apply small

amount of Loctite 222 thread locker to thread of poppet retainer, taking

care not to get Loctite on poppet or other inlet check valve sealing

surfaces.

5. Tighten poppet retainer (11) using 1/2-in. flat blade screwdriver taking

care not to twist off poppet retainer. If torque wrench tools are

available, tighten to 25-30 in-lbs.

6. Inspect the assembled unit to insure the following:

• The poppet moves freely.

• The spring is fully guided on the poppet retainer.

• The spring end is 90° from the retainer’s screwdriver slot.

• The poppet retainer is shouldered against the sealing head.

Figure 7-9 HP Check Valve Inlet Cutting Water

Item Description

(1) Sealing Head (2) Poppet (7) Spring (11) Poppet Retainer

Loading...

Loading...