SECTION 7

HIGH PRESSURE WATER

p. 7-23

80078868

7.3.4 HP Cylinder

1. At a workbench, use the seal removal tool to prevent scratching the

cylinder bore sealing surface. Use a pulling action to remove the sealing

head HP seal.

2. Remove the bore liner. Use a plastic-faced hammer and the seal removal

tool to drive out the plunger HP seal and follower. Be careful not to

scratch the bore of the cylinder or damage the cylinder threads.

3. Clean sealing areas of HP cylinder inside diameter and inspect cylinder

for rings, scratches, pits, residue build-up and other potential leak paths.

Seal material or residue can build up forming a ring, and running a

fingernail across it, will cause it to appear as a surface flaw. It is usually

necessary to clean the area before performing an inspection.

4. Use 600 grit wet/dry sandpaper to polish HP cylinder inside diameter

where the seal will locate. Polish only in a circumferential motion. Do

not polish or drag the sandpaper along the length of the cylinder. Hold

the sandpaper on the end of your finger, and move in a cylindrical

wiping motion in the bore of the HP cylinder. Wipe residue from

cylinder inside diameter and re-inspect for surface defects.

NOTE

The HP cylinder ends often show a “step” between inner and outer

sleeves where the inner sleeve extends beyond the outer by a small

amount. This is normal and does not indicate a flaw in the cylinder.

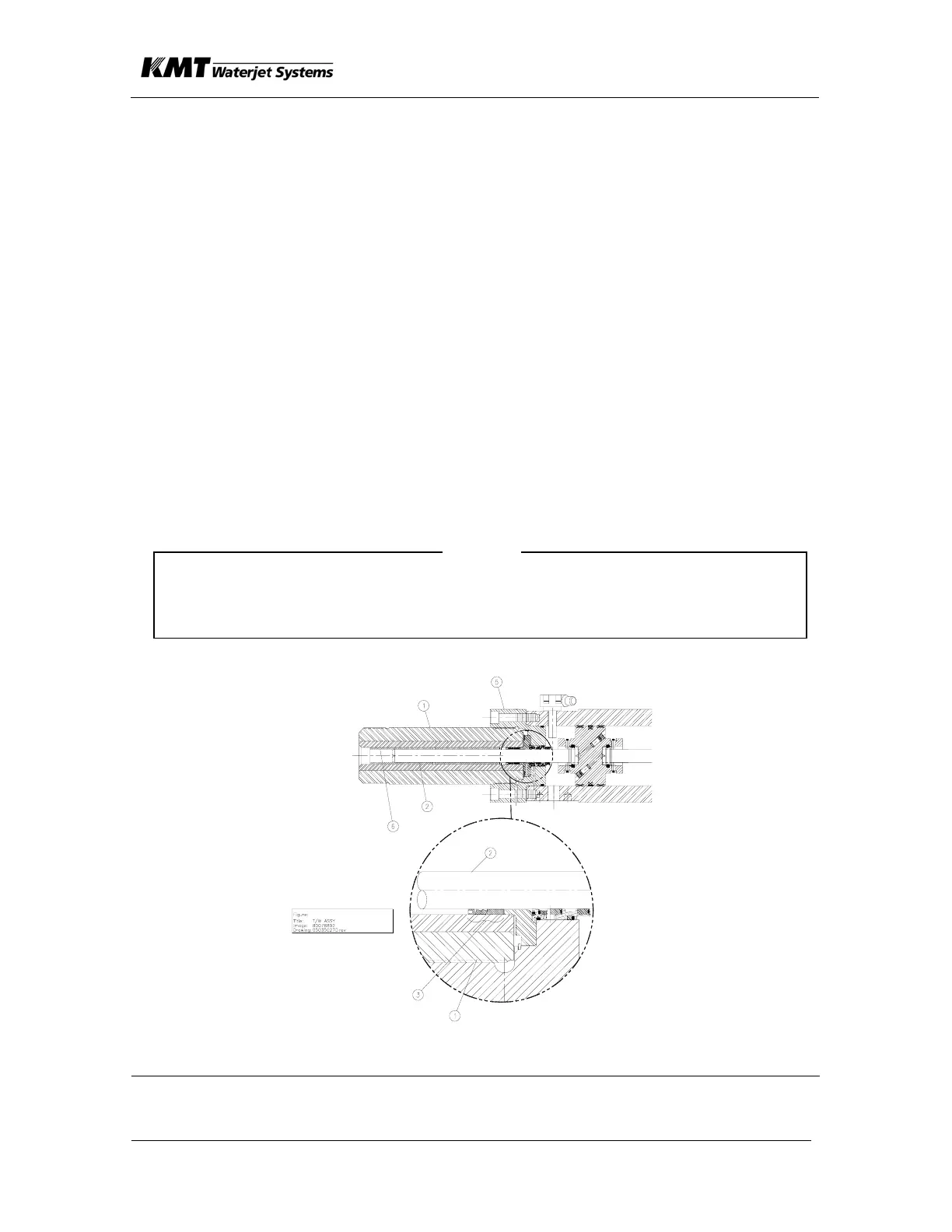

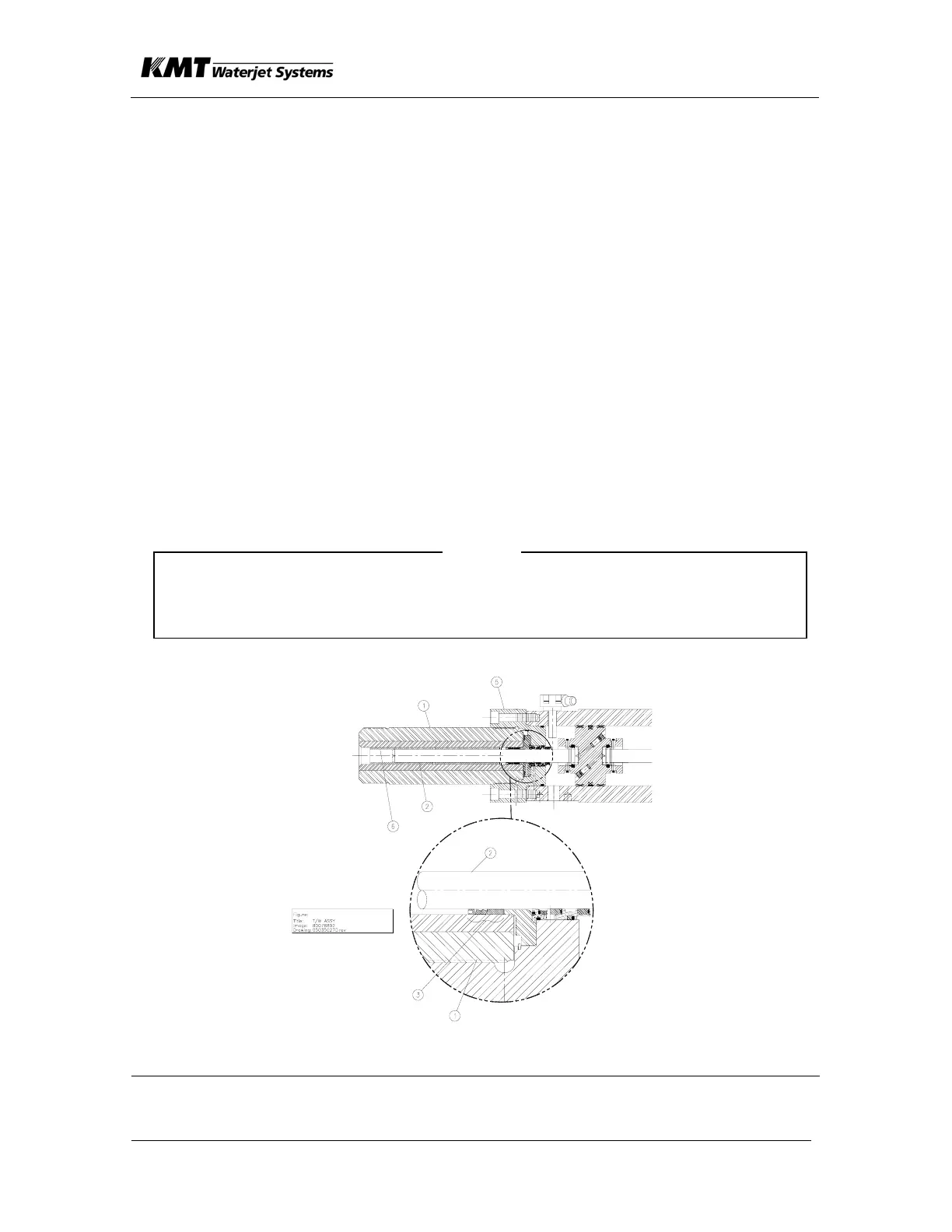

Figure 7-12

Item Description

(1) Cylinder Body (5) Cylinder Head

(2) Plunger (6) Liner

(3) Plunger Seal Follower

Loading...

Loading...