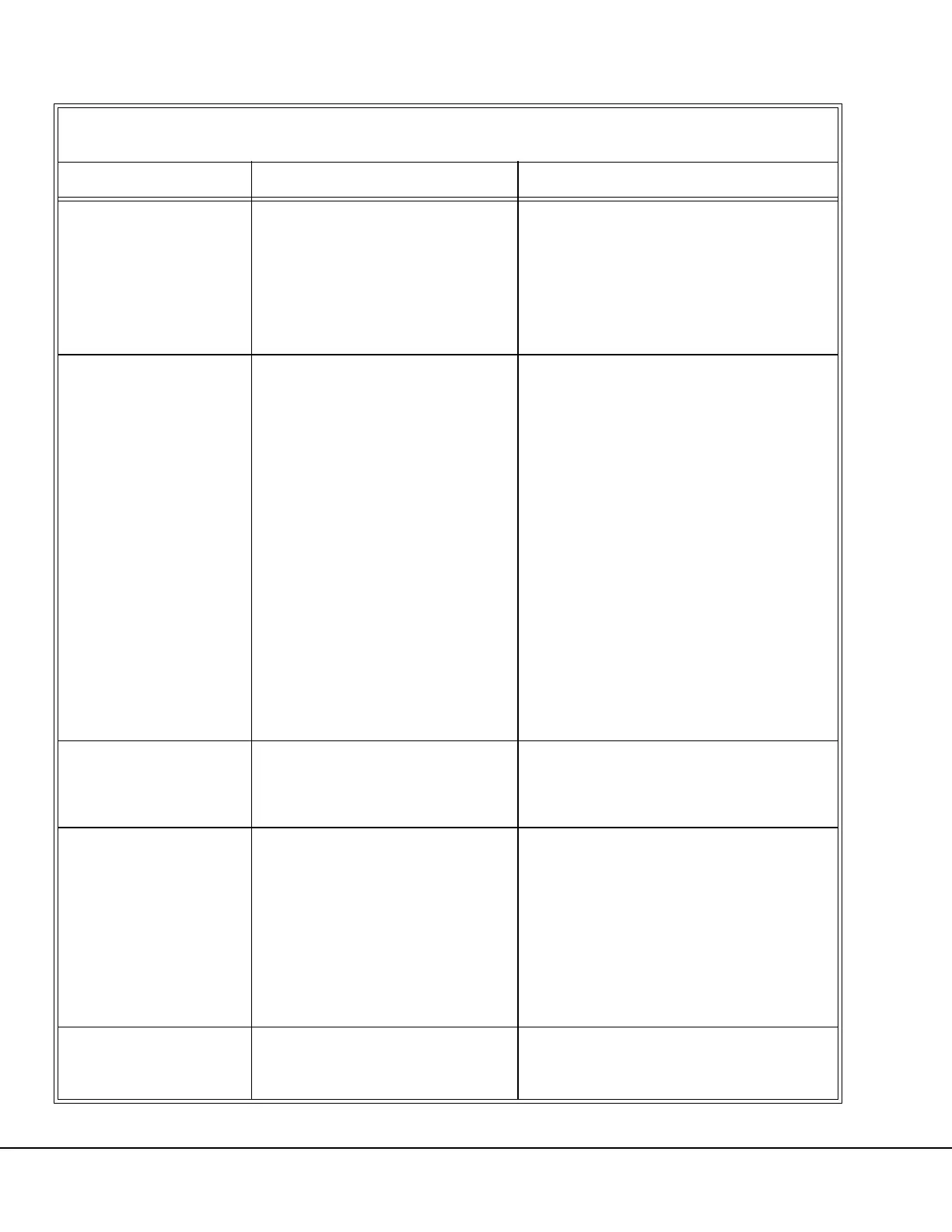

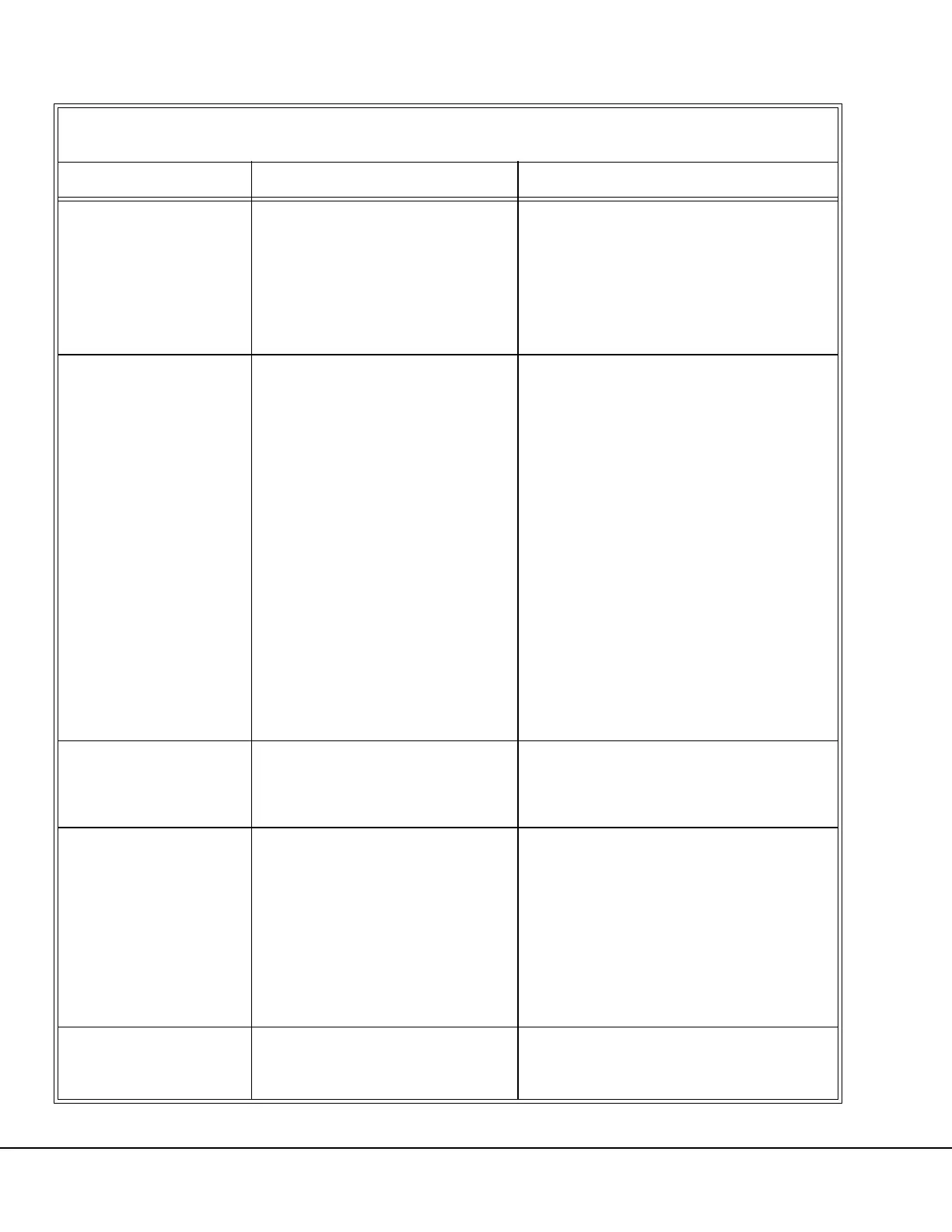

L10-8 Hydraulic Check-out Procedure 05/03 L10016

TROUBLESHOOTING CHART

(Steering Pump)

Trouble Possible Cause Suggested Corrective Action

No pump output

Trapped air inside steering pump.

Broken pump drive shaft.

Excessive circuit leakage.

No oil to pump inlet.

Bleed trapped air. Refer to “Pressure Check

And Adjustment Procedure”, this Section.

Replace pump drive shaft.

Check for loose fittings, broken or cracked

tubes.

Check hydraulic tank oil level. Make sure

shut-off valve is open.

Low pump output

Low pump pressure.

Compensator valve, seat, spring or

packing failure.

Worn or scored pistons and bores.

Maximum volume stop limiting

pump stroke.

Worn or damaged piston shoes,

swashblock or swashblock wear

plate.

Worn or grooved cylinder wear plate

and/or port plate.

Restricted inlet.

Insufficient inlet oil.

Check or adjust compensator pressure set-

ting.

Repair or replace compensator.

Repair or replace pistons or pump housings.

Turn volume stop screw counterclockwise.

Tighten jam nut.

Repair or replace defective parts.

Repair or replace defective parts.

Clear restriction. Make sure suction line

shut-off valve is open. Clean suction

strainer.

Check for proper hydraulic tank oil level and

make sure suction line shut-off valve is

open.

Unresponsive or slug-

gish control

Control piston seals broken or dam-

aged.

Swashblock saddle bearings worn

or damaged.

Repair or replace broken parts.

Repair or replace broken parts.

Loss of pressure

Faulty output circuit components.

Worn piston pump.

Worn or grooved cylinder wear plate

and/or port plate: wear plate and/or

port plate separation from cylinder,

each other or valve plate.

Worn pistons, shoes or piston

bores.

Repair or replace relief valve or pressure

compensator valve.

Repair or replace worn parts.

Repair or replace worn parts.

Repair or replace worn parts.

Excessive or high peak

pressure

Faulty output circuit components. Repair or replace relief valve or pressure

compensator valve.

Loading...

Loading...