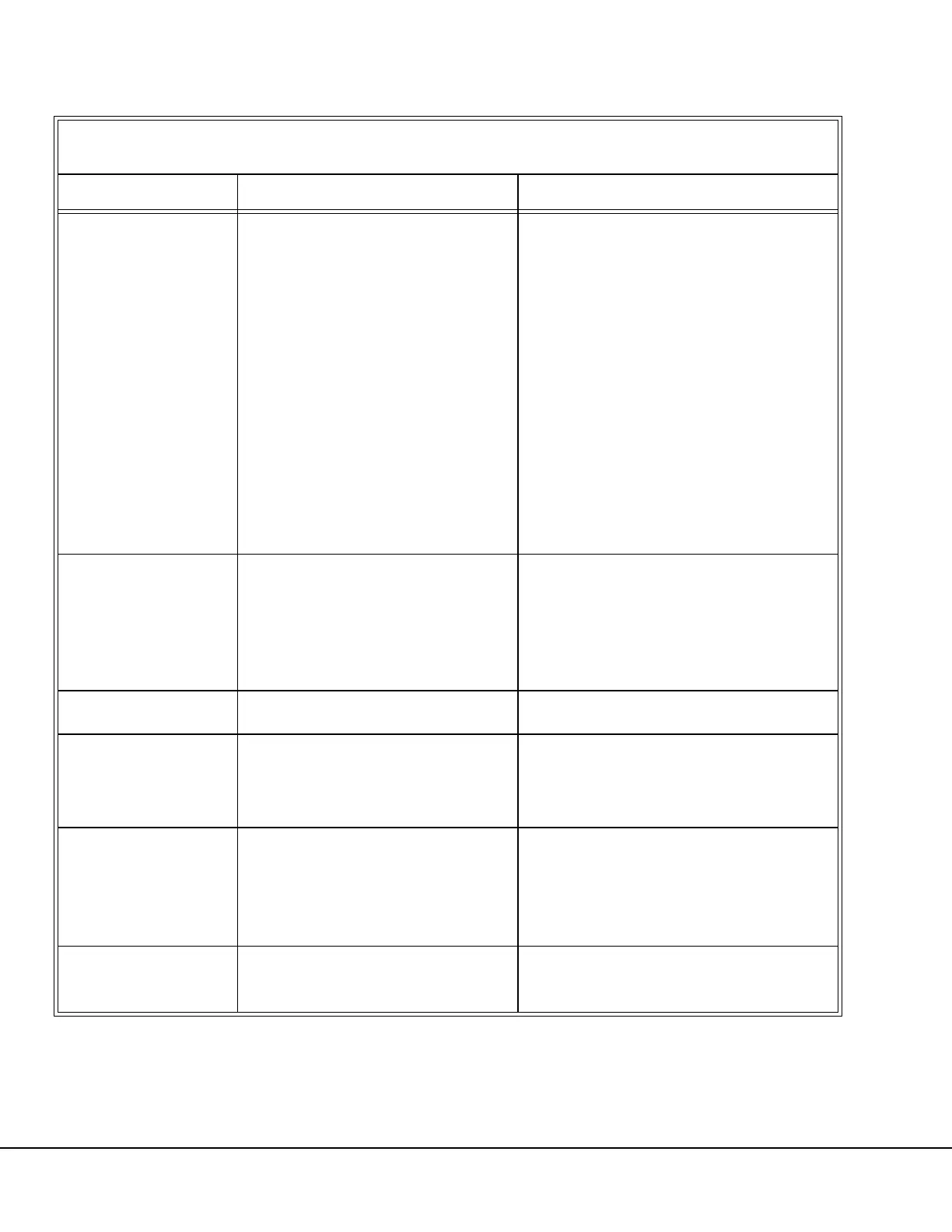

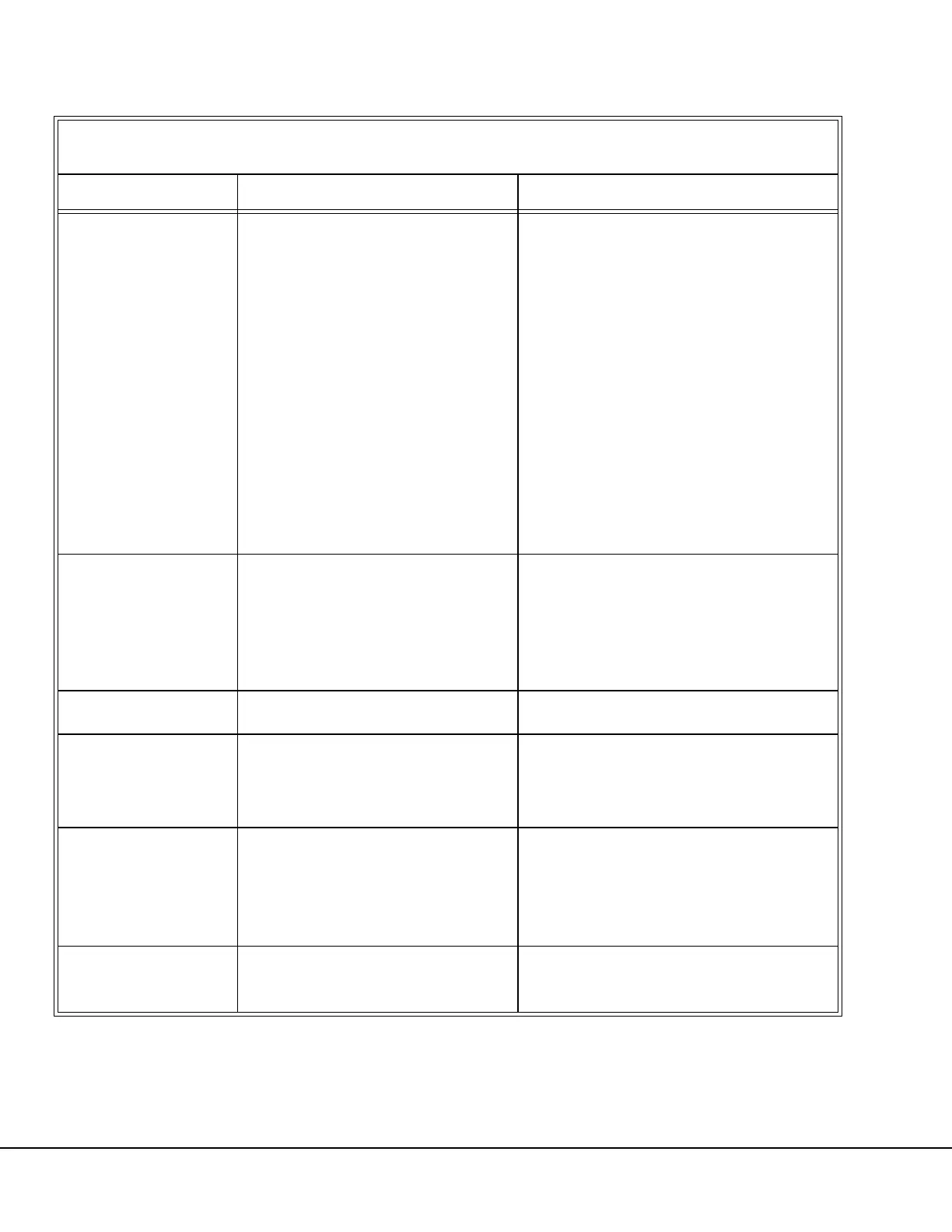

L10-16 Hydraulic Check-out Procedure 05/03 L10016

TROUBLESHOOTING CHART

(Hoist Pump)

Trouble Possible Cause Suggested Corrective Action

Visible damage in the

following areas:

• Sandblasted band

around pressure plate

bores

• Angle groove on

face of pressure plate

• Lube groove

enlarged and edges

rounded

• Dull area on shaft at

root of tooth

• Dull finish on shaft

in bearing area

• Sandblasted gear

bore in housing

Abrasive wear caused by fine parti-

cles in oil supply — Dirt (fine contami-

nants, not visible to the eye).

Change hydraulic oil.

Hydraulic filters may need changing.

Verify correct filter elements are being used.

Check hoist and steering cylinders for dents,

scoring, or seal damage.

Entire hydraulic system may require com-

plete cleaning (See “Flushing Procedure” in

the following pages).

Visible damage in the

following areas:

• Scored pressure

plates

• Scored shafts

• Scored gear bore

Abrasive wear caused by metal parti-

cles — Metal (coarse contaminants,

visible to the eye).

Entire hydraulic system may require com-

plete cleaning (See “Flushing Procedure” in

the following pages).

Check other hydraulic system components

for possible source of contaminants.

External damage to

pump

Incorrect installation. Remove and repair as required.

Damage on rear of

drive gear and rear

pressure plate only

Defective pump driveshaft.

Check pump driveshaft.

Check cross and bearings for smooth oper-

ation.

Check for adequate joint lubrication.

Eroded pump hous-

ing or pressure plate

Aeration - cavitation

• Restricted oil flow to pump

• Aerated oil

Check hydraulic tank oil level.

Verify correct oil viscosity.

Check for restriction or air leak at pump inlet

line.

Check for loose fittings, clamps etc.

Excessive wear on

pressure plate and/or

end of gear

Lack of oil.

Check hydraulic oil level.

Check pump inlet hoses for obstructions or

leaks.

Loading...

Loading...