2FB/2FC-4

1-5-11

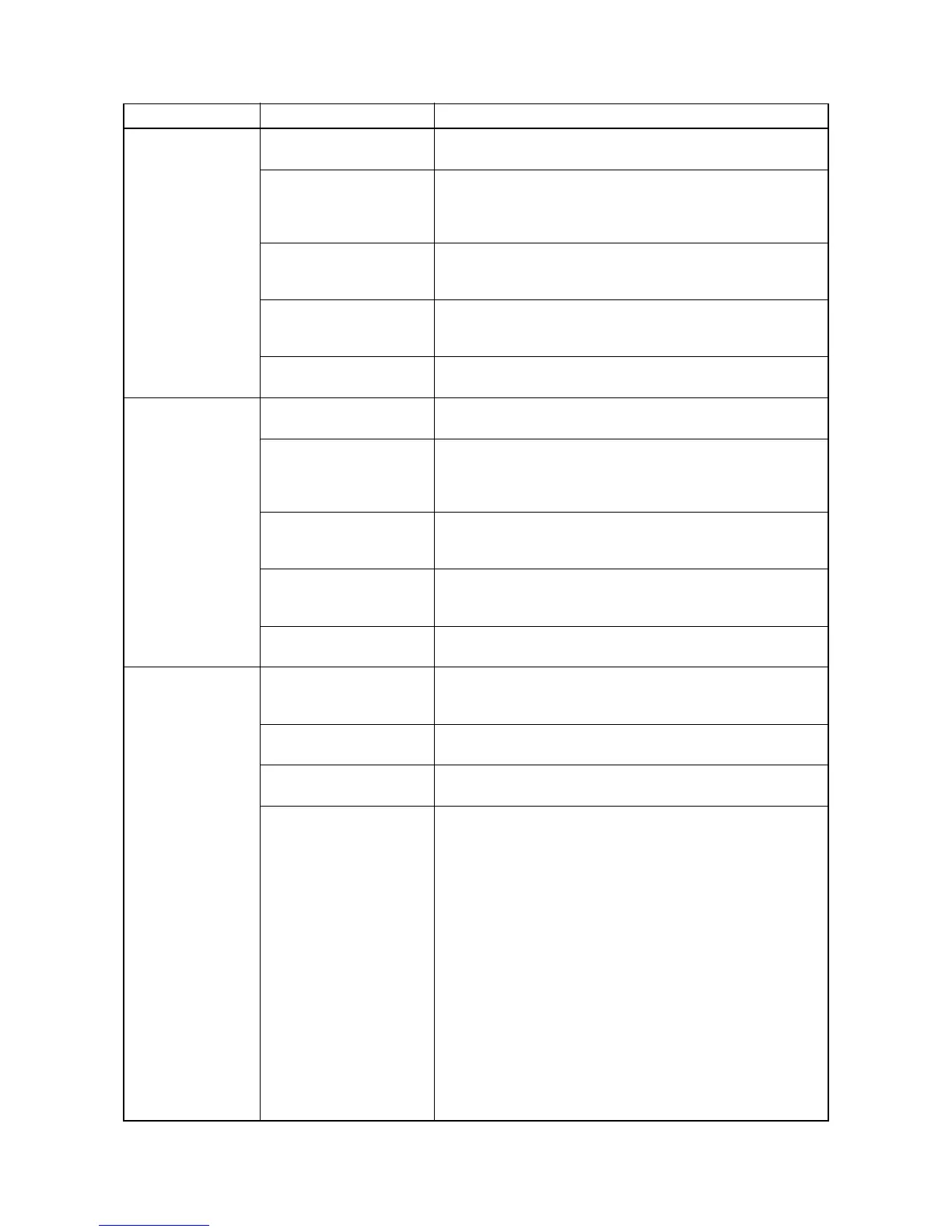

(4)

A paper jam in the

paper feed section is

indicated during

copying (no paper

feed from cassette

3).

Jam code 12

Paper in cassette 3 is

extremely curled.

Change the paper.

Check if the paper feed pul-

ley, forwarding pulley and

separation pulley of cas-

sette 3 are deformed.

Check visually and replace any deformed pulleys.

Defective timing switch 2. Run maintenance item U031 and turn the timing switch 2 on and

off manually. Replace the timing switch 2 if indication of the corre-

sponding sensor on the touch panel is not displayed in reverse.

Check if paper feed motor 3

malfunctions.

Run maintenance item U030 and select paper feed motor 3 on the

touch panel to be turned on and off. Check the status and remedy

if necessary.

Electrical problem with

paper feed motor 3.

Check (see page 1-5-62).

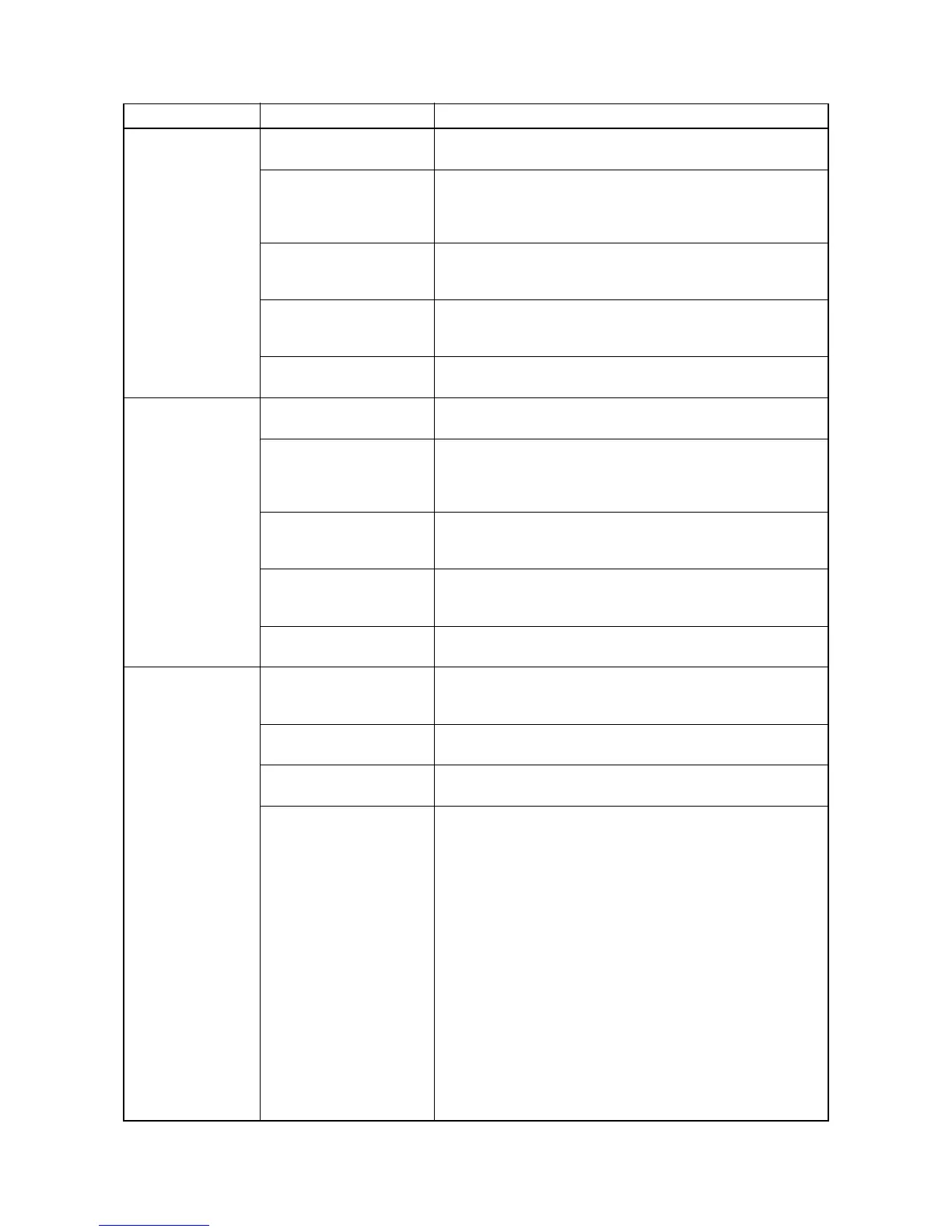

(5)

A paper jam in the

paper feed section is

indicated during

copying (no paper

feed from cassette

4).

Jam code 13

Paper in cassette 4 is

extremely curled.

Change the paper.

Check if the paper feed pul-

ley, forwarding pulley and

separation pulley of cas-

sette 4 are deformed.

Check visually and replace any deformed pulleys.

Defective timing switch 3. Run maintenance item U031 and turn timing switch 3 on and off

manually. Replace timing switch 3 if indication of the correspond-

ing sensor on the touch panel is not displayed in reverse.

Check if paper feed motor 4

malfunctions.

Run maintenance item U032 and select paper feed motor 4 on the

touch panel to be turned on and off. Check the status and remedy

if necessary.

Electrical problem with

paper feed motor 4.

Check (see page 1-5-62).

(6)

A paper jam in the

paper feed section is

indicated during

copying (no paper

feed from optional

side feeder).

Jam code 14

Check if the side feeder

feed clutch malfunctions.

Run maintenance item U247 and select the side feeder feed

clutch on the touch panel to be turned on and off. Check the status

and remedy if necessary.

Electrical problem with the

side feeder feed clutch.

Check.

Broken side feeder feed

switch actuator.

Check visually and replace the side feeder feed switch if its actua-

tor is broken.

Defective side feeder feed

switch.

Run maintenance item U031 and turn the side feeder feed switch

on and off manually. Replace the side feeder feed switch if indica-

tion of the corresponding sensor on the touch panel is not dis-

played in reverse.

Problem

Causes/check procedures

Corrective measures

Loading...

Loading...