Theory of operation

POR sequence

As the printer is turned on, the engine code goes through a series of tests to verify hardware integrity. If a

hardware failure is detected, then it is reported to the printer. If the POR sequence cannot be completed

successfully, then the printer may post an error message. The message states that service may be needed.

Printer control

The printer uses a single processor for both RIP and engine functions. The raster image processor (RIP) code

performs system responsibilities such as PC connection, LAN, ISP attachments, and bitmap generation. The

engine code performs tasks related to the operation of the electrical and mechanical device systems such as

motors, lasers, power supplies, and fusers. The NVRAMs are located on the controller board and control panel,

replacement of either the controller board or control panel will pull or mirror NVRAM data from each other.

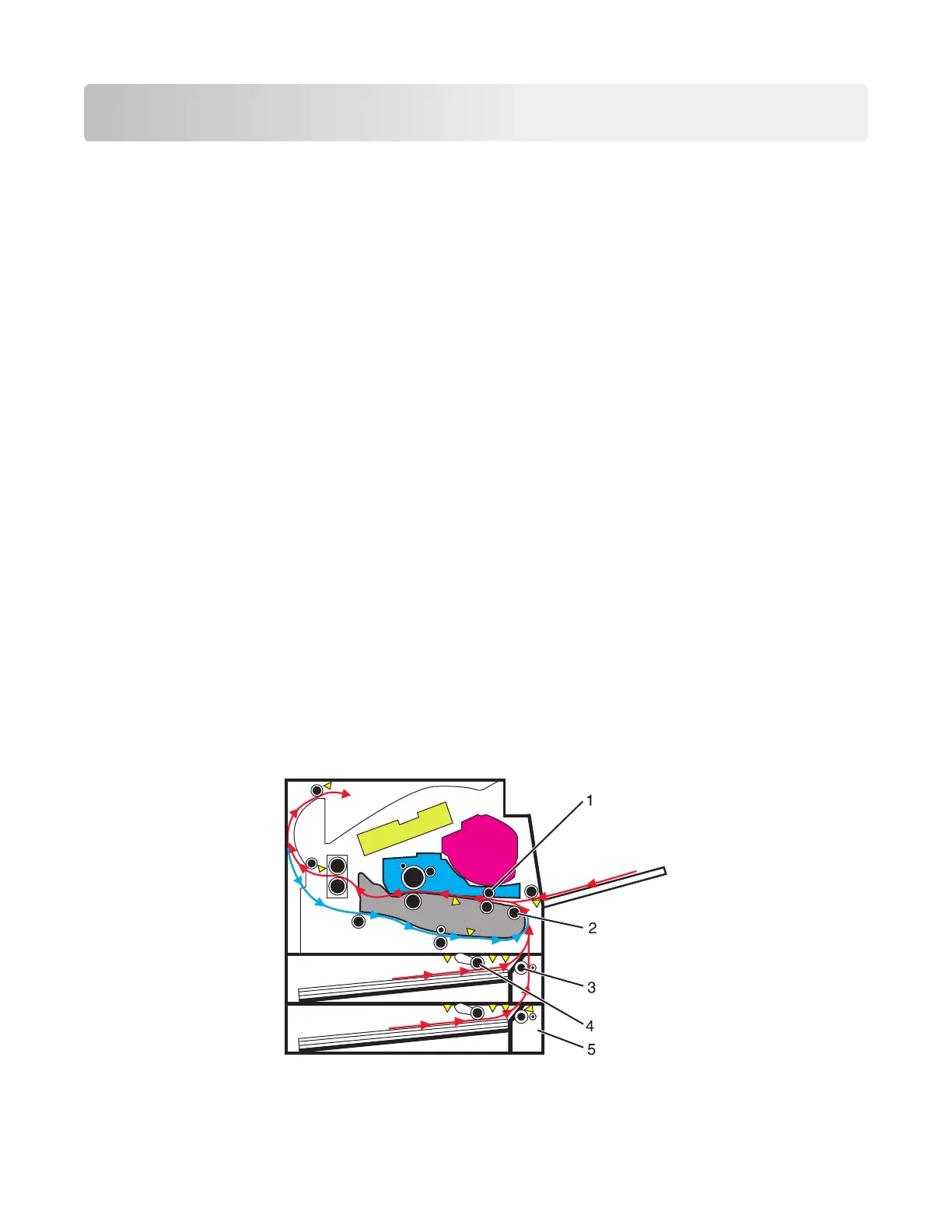

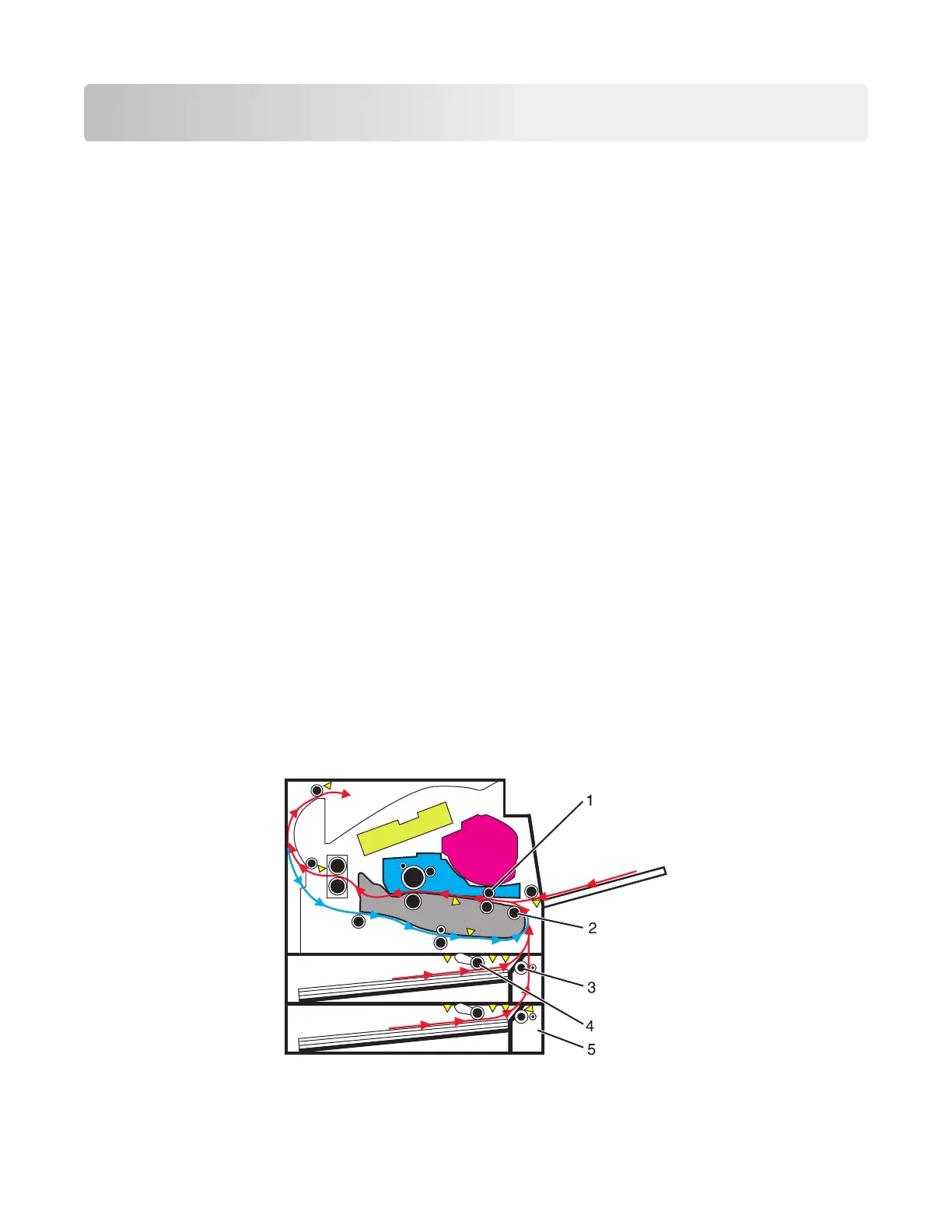

Paper path information

Input tray

Component functions for feeding from the tray:

• Tray present sensor—Detects if the tray is inserted

• Media present sensor—Detects whether the media level is empty or low.

• Pick/Lift motor—Supplies the mechanical power requirements of the lift plate and the pick rollers.

When feeding media, the front part of the lift plate is raised, pressing the media to the pick rollers. The pick

rollers rotate to feed the media to the separator rolls. The separator rolls rotate in a direction opposite to the

pick rollers. This ensures that sheets are fed one at a time. The media is then fed to the secondary input roller

and then to the first input roller.

4514-6xx

Theory of operation

365

Loading...

Loading...