Page 10 of 76

Mounting guidelines

• The mounting pins must have the correct dimension

• The bolts and nuts must be made of a high quality steel grade (e.g. 10.8). No thread

on the bolt inside the back fixture or the piston rod eye

• Bolts and nuts must be protected so there is no risk for them to fall out

• Do not use a torque that is too high when mounting the bolts for the back fixture or

he piston rod eye. This will stress the fixtures

Please note:

The piston rod eye is only allowed to turn 0-90 degrees.

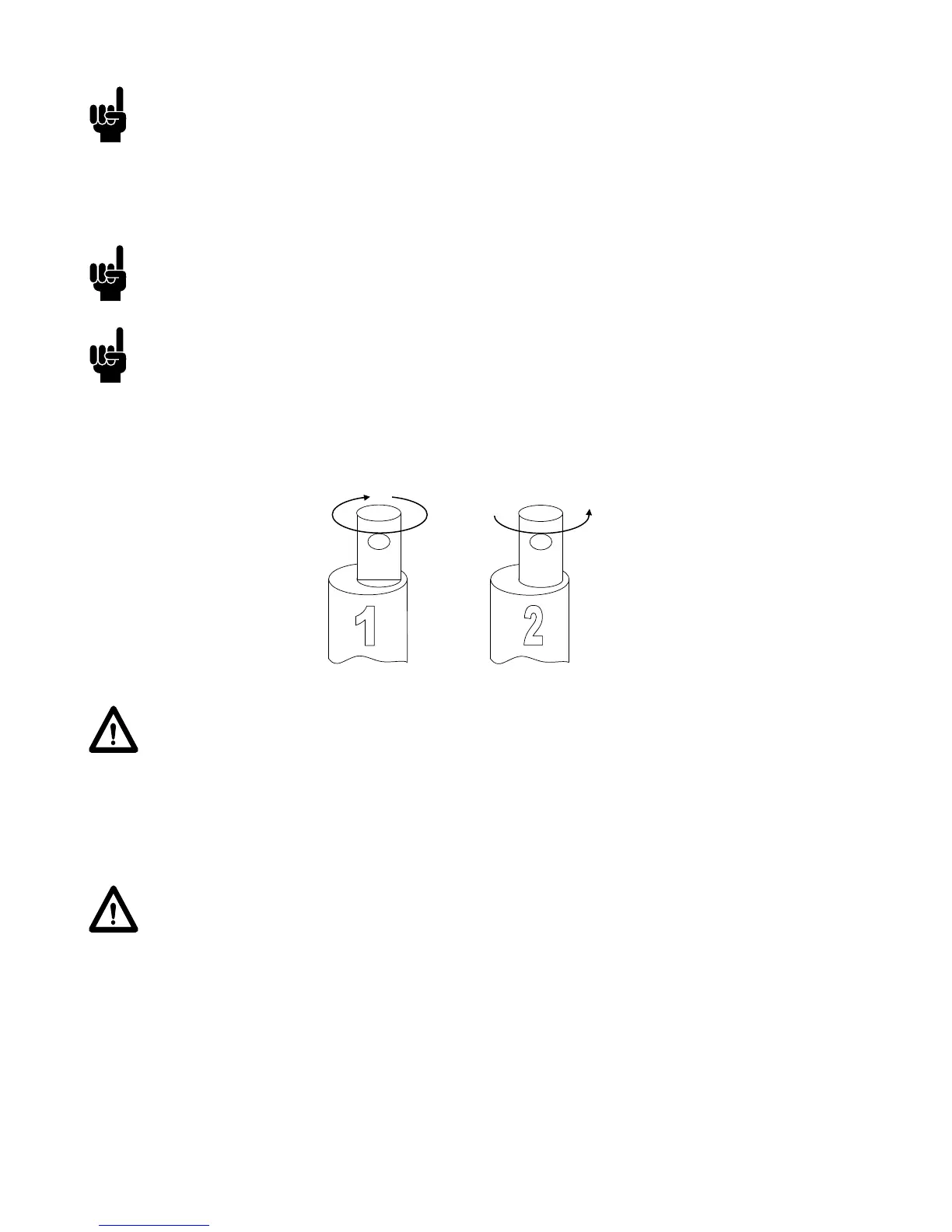

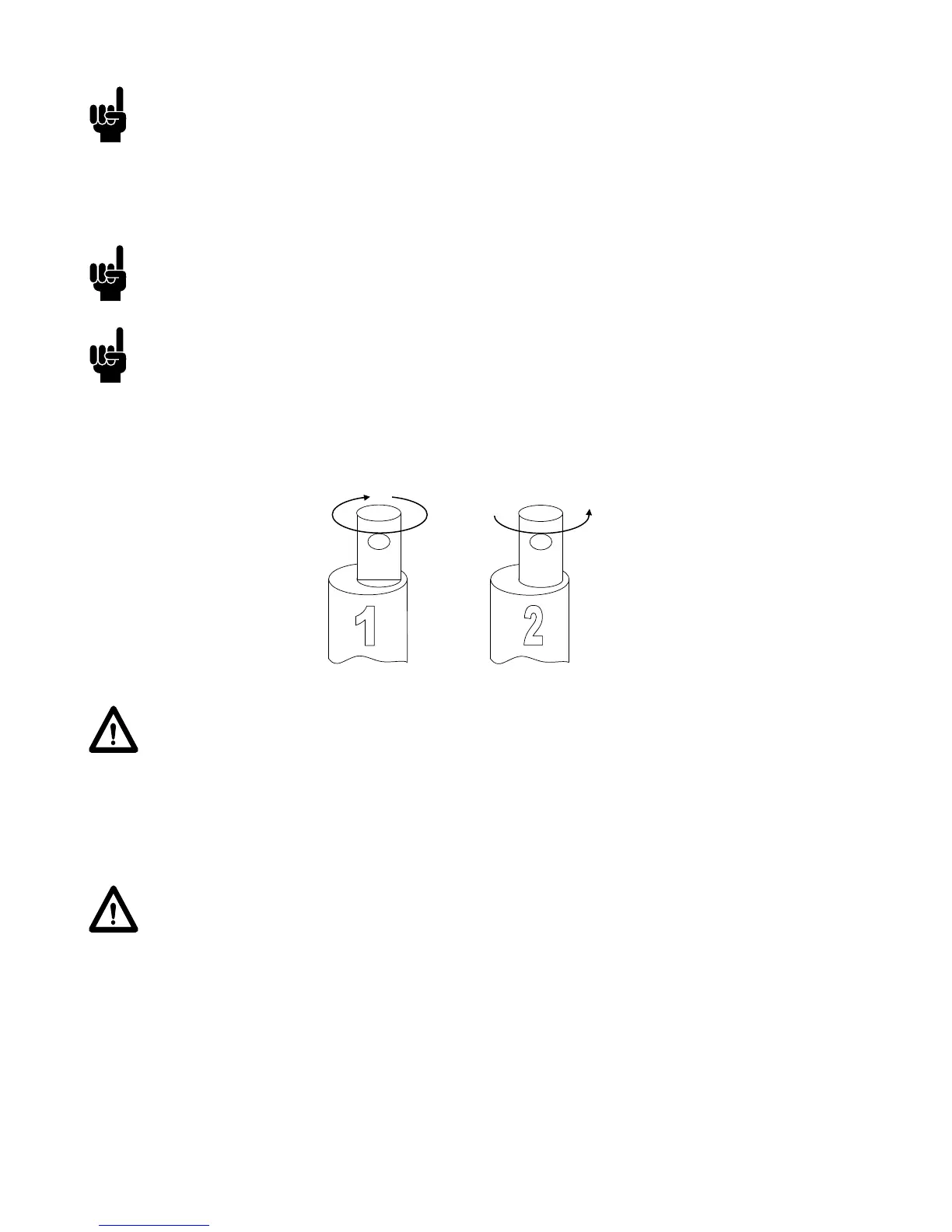

Instruction concerning the turning of the piston rod eye:

When mounting and taking into use, it is not permitted to make excessive turns of the

piston rod eye. In cases where the eye is not positioned correctly, it is permitted to first

screw the eye down to its bottom position, at a maximum torque of 2Nm (1), and thereaf-

ter a maximum half turn outwards again (2).

Warning!

If the actuator is used for pull in an application where personal injury can occur,

the following is valid:

It is the application manufacturer’s responsibility to incorporate a suitable safety

arrangement, which will prevent personal injury from occurring, if the actuator should

fail

Warning!

LINAK’s actuators are not designed for use within the following fields:

• Offshore installations

• Aeroplanes and other aircraft

• Nuclear power generation

SD/816030

Instruktion vedr. uddrejning af inderrør – LA27 + LA27C

Til salesbackup, brugsanvisning og datablad.

Ved montage og ibrugtagning, er det ikke tilladt at dreje unødvendigt mange gange på

stempelstangsrøret. Hvis øjet ikke er positioneret korrekt, er det tilladt først at skrue

røret i bund (1), og derefter skrue det maksimalt ½ omgang ud igen (2).

Loading...

Loading...