Page 18 of 76

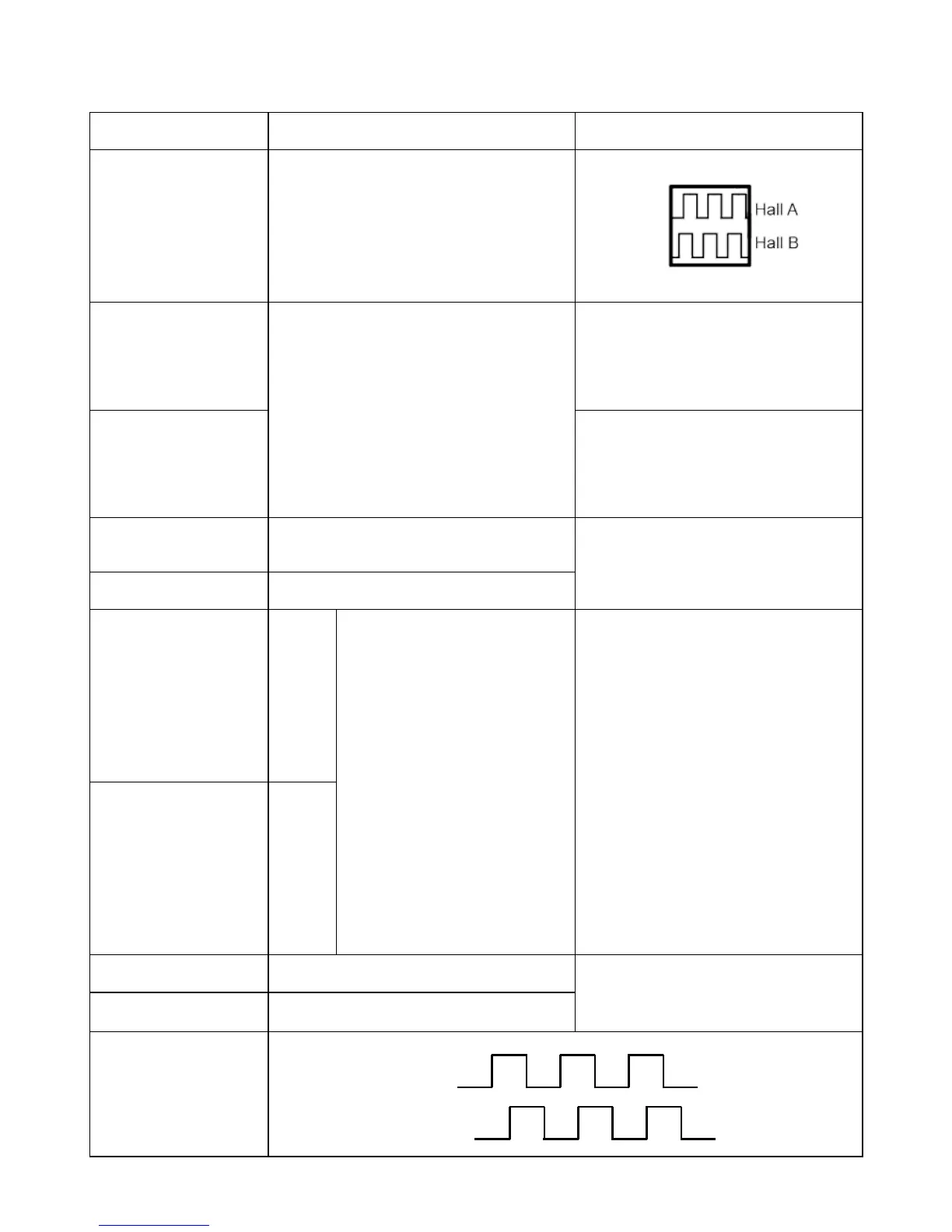

Actuator with endstop signals and relative positioning - Dual Hall:

I/O specifications:

Input/Output Specification Comments

Description The actuator can be equipped

with Dual Hall that gives a relative

positioning feedback signal when

the actuator moves.

See connection diagram,

fig. 4, page 17

Brown 12, 24 or 36VDC (+/-)

12V ± 20%

24V ± 10%

36V ± 10%

Under normal conditions:

12V, max. 26A depending on load

24V, max. 13A depending on load

36V, max. 10A depending on load

To extend actuator:

Connect Brown to positive

To retract actuator:

Connect Brown to negative

Blue To extend actuator:

Connect Blue to negative

To retract actuator:

Connect Blue to positive

Red Signal power supply (+)

12-24VDC

Current consumption:

Max. 40mA, also when the

actuator is not running

Black Signal power supply GND (-)

Green Hall B

Movement per single hall

pulse:

LA362C Actuator = 0.4

mm per pulse

LA363C Actuator = 0.7

mm per pulse

LA363B Actuator = 1.0 mm

per pulse

LA363A Actuator = 1.7

mm per pulse

LA365A Actuator = 2.9

mm per pulse

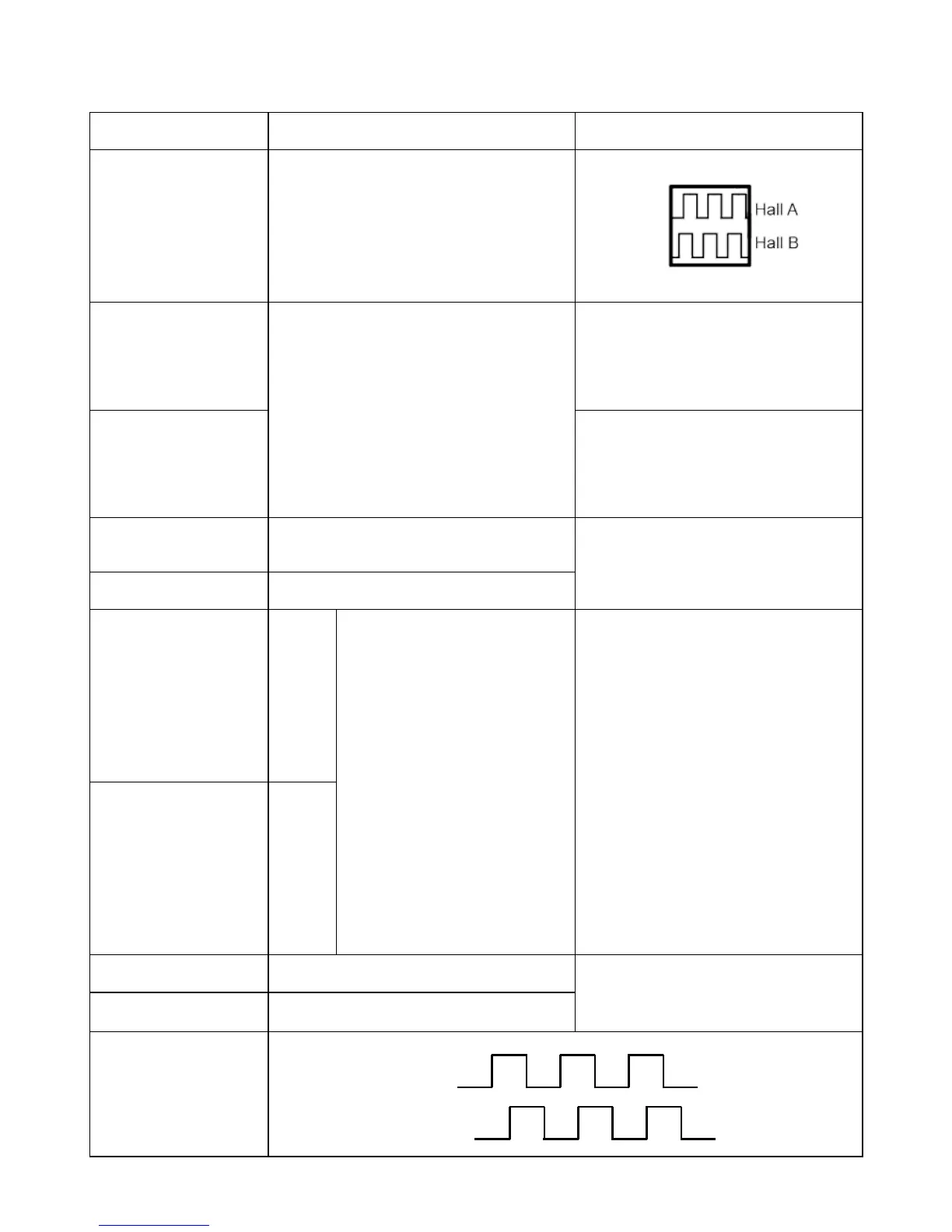

The Hall sensor signals are gener-

ated by the turning of the actua-

tor gearing. These signals can be

fed into a PLC (Programmable

Logic Controller). In the PLC the

quadrature signals can be used to

register the direction and position

of the piston rod.

Output voltage min. V

IN

- 1V

Current output 12mA

Overvoltage on the motor can

result in shorter pulses.

N.B. For more precise measure-

ments, please contact LINAK A/S.

Yellow Hall A

Violet Endstop signal in Output voltage min. V

IN

- 2V

Source current max. 30mA

NOT potential free

White Endstop signal out

Diagram of Dual

Hall:

Fig. 4.1

Hall B

Hall A

Loading...

Loading...