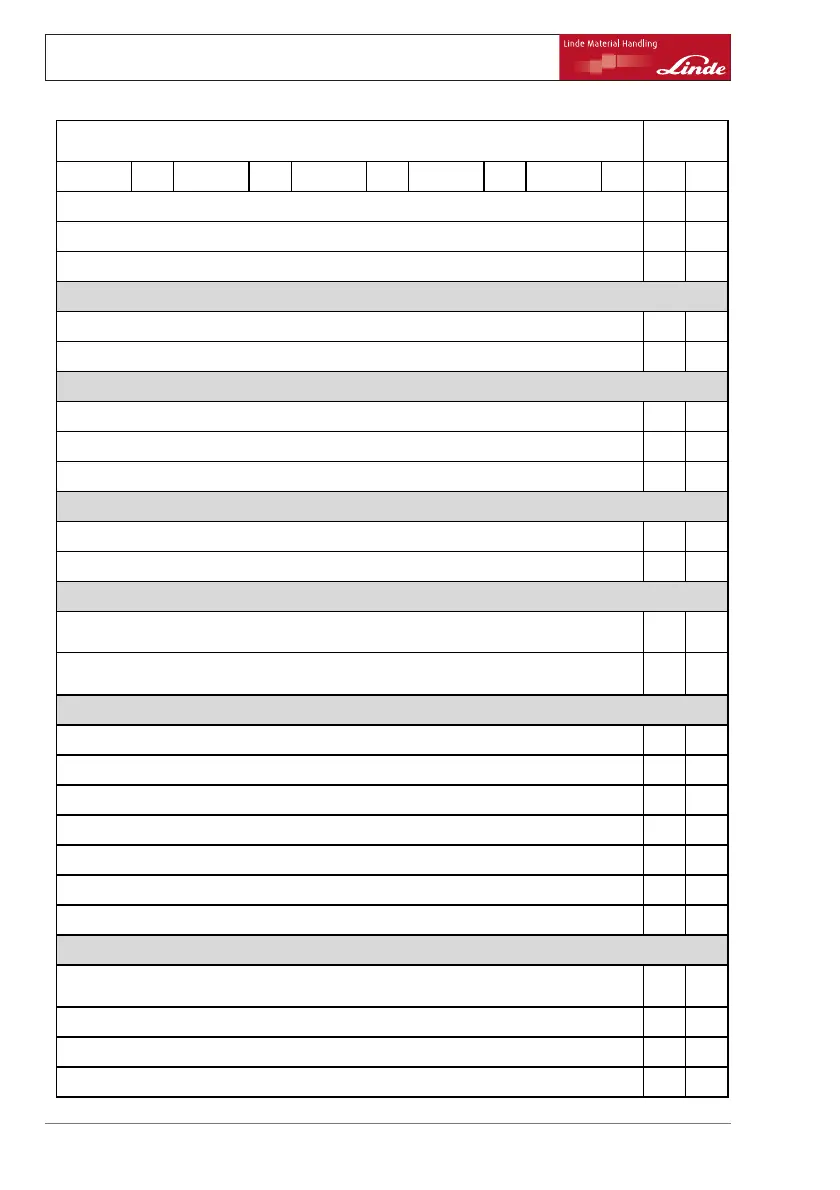

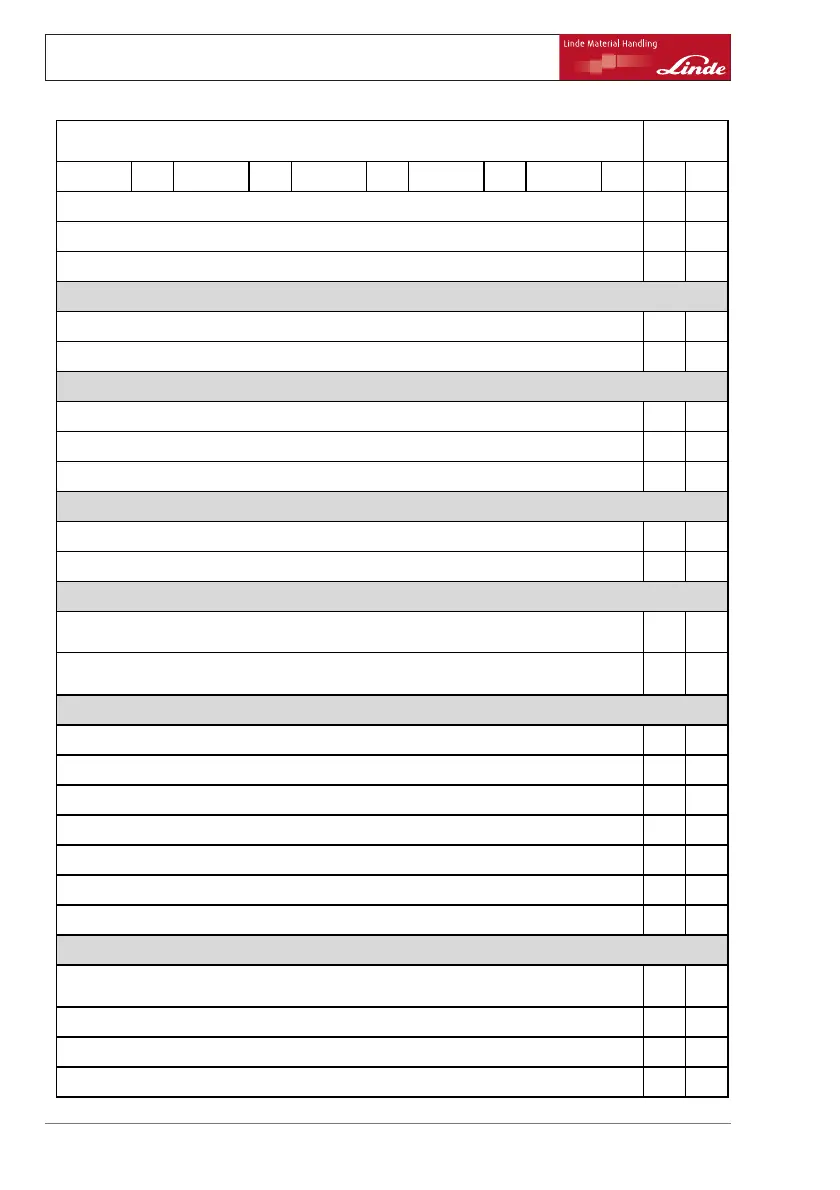

5 Maintenance

Inspection and maintenance overview

At operating hours

Carried

out

9000 18000

9

8

Drive axle: check the side stops

Drive axle: check the bearing for wear

Hydraulic pump on engine:

check the mountings

Chassis, bodywork and fittings

Chassis, tilt cylinders and steering axle: check the mountings

Check and grease other bearings and joints

Chassis frame

Check the parking brake for correct operation

Clean and grease steering axle

Steering cylinder and steering pivot pin: check the mountings

Controls

Check and oil the pedals

Check the bellows at the actuating lever

Electrics

Check the condition and secure positioning of electric cables, cable connectors and

connections

Battery: Check condition, acid level and acid density (even for maintenance-free

batteries)

Hydraulics

Change th

e hydraulic oil (omitted for 9000 operating hours)

Hydrauli

c system: Check the oil level.

Check th

e bleeder valve on the hydraulic oil tank for correct operation

Change f

eed/pressure/suction filter and breather filter of the hydraulic system

Check t

he hydraulic system for leaks

Check

tilt cylinder bearing for wear

Doubl

e hoses: check the pre-load

Load

lift system

Check the condition, secure mounting and function of the lift mast, lift mast chain, lift

cylinder and end stops

Adjust lift mast chain and spray with chain spray

Check fork arms and arm safety devices

Clean and grease the sideshift, check the mounting

118 Operating Instructions – 394 807 10 01 EN – 07/2011

Loading...

Loading...