Maintenance 5

Engine

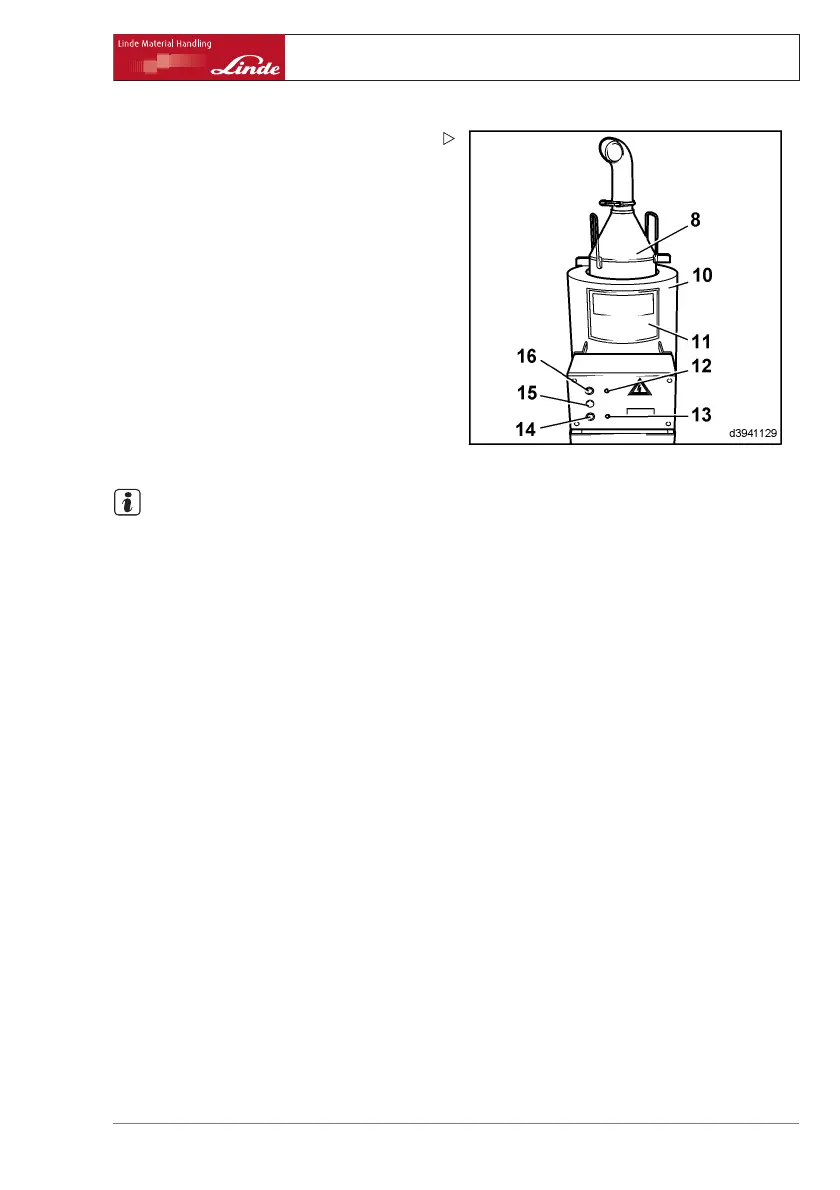

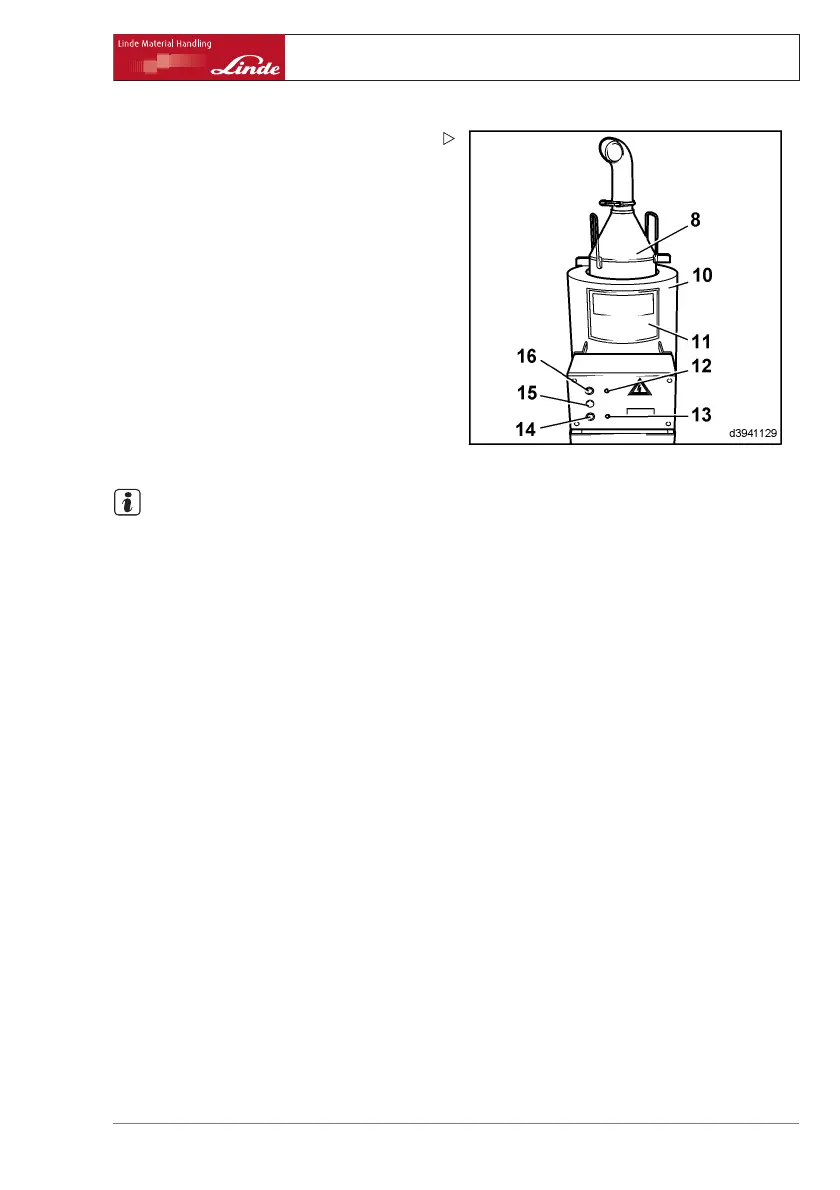

Press the STOP switch (15) in the event of

danger.

Only press the STOP switch in an emergency!

The filter must then be fully regenerated again.

An indicator light (13) will il

luminate if there

is a malfunction during regene

ration. Press

the acknowledgement button

(14). If the

error persists, please cont

act your authorised

dealer.

¾ Remove the particle filter from the regener-

ator.

¾ Reattach the particle filter to the truck.

The opening of the tailpip

e must point to the

right.

¾ Check the filter is securely in place.

NOTE

When closing the quick-

locking mechanism

(9), an end limit switch

automatically sets the

built-in hour meter to

zero.

Checking the particl

e filter system

(special equipment

)

¾ Check electric cont

acts for secure position-

ing, corrosion and d

amage.

¾ Check the combustion air ducts for damage,

leaks and secure positioning.

¾ Check the fuel-conducting lines and parts

for damage, leaks and secure positioning.

¾ Check that the syst

em functions correctly

(alarm, buzzer, re

generation).

¾ Check burner fastenings for leaks, defor-

mation and secure positioning.

¾ Clean the corrugated hose and the connec-

tion angle (fan to the burner).

¾ Check that the fil

ter suspension points are

securely fitted.

¾ Check the exhaust-gas-conducting parts

for leaks.

¾ Clean the air intake pipe on the burner.

Operating Instructions – 394 807 10 01 EN – 07/2011 151

Loading...

Loading...