5 Maintenance

Hydraulics

Check the hydraulic system for leaks

¾ Open the bonnet.

¾ Raise and secure the floor plate.

¾ Check all connections betwee

n the oil tank,

drive motors, pumps and contr

ol valves for

leaks.

¾ Tighten connections if necessary.

¾ Check the lift, tilt and steering cylinders for

leaks.

¾ Replace any porous hoses.

¾ Inspect the lines for chafing and replace, if

necessary.

¾ Close the floor plate.

¾ Close the bonnet.

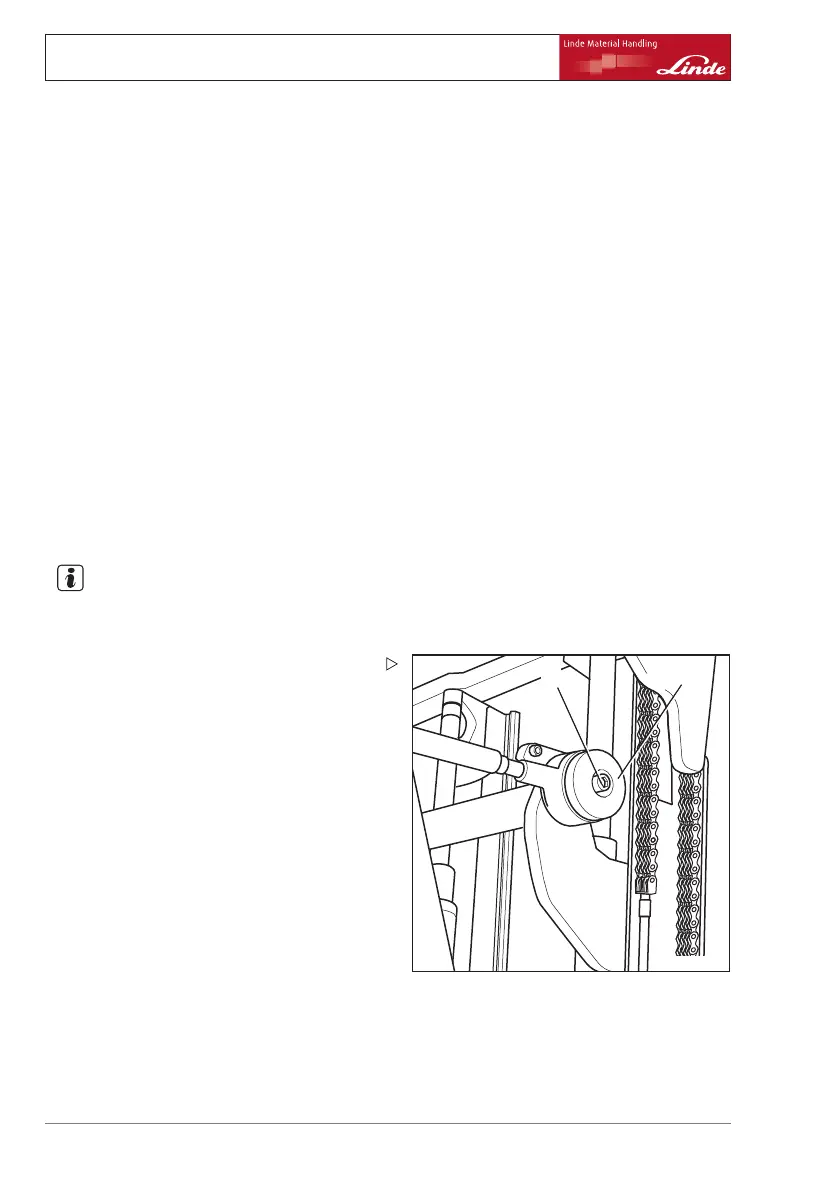

Check tilt cylinder bea

rings for wear

NOTE

The tilt cylinders are mounted in rubber

bearings at both ends.

d3921471

1

2

¾ Remove the screw (1) at the disc (2).

¾ Make a visual inspec

tion of the rubber

bearings for cracks

.

The rubber should not have any cracks.

¾ Check the rubber bearing at the front and

rear of each tilt cylinder.

When a rubber bear

ing is worn or damaged,

renew it. Please c

ontact your authorised

dealer.

180 Operating Instructions – 394 807 10 01 EN – 07/2011

Loading...

Loading...