V. 1.0 | LPKF Laser & Electronics AG

7 Maintenance

This chapter contains important information about maintenance of the system.

Proper maintenance and the proper operation of the corresponding supply units – in

this case the extraction system – are basic requirements for a smooth function of the

system.

Maintenance has to be performed and documented regularly according to the

manufacturer's instructions.

The system is designed for a service life of 10 years used in one-shift operation (10

hours a day). The specified maintenance intervals are valid for one-shift operation at 5

days a week.

7.1 Safety

Follow the safety instructions below for your own protection and for the protection of

other persons in the vicinity of the maintenance work. The maintenance personnel

must ensure that the described prerequisites for the planned maintenance tasks are

fulfilled and they must observe the special warning messages for the individual

maintenance tasks.

Danger to life by electrical shock!

Touching energized parts causes a direct danger to life by electrical shock. Damage

to the insulation or damaged individual parts can be dangerous to life.

All work on energized components of the system must be performed by a

qualified electrician.

If the insulation is damaged, switch off the power supply immediately and initiate

the repair.

De-energize all energized components of the system or equipment, before

working with them. Ensure that the system or equipment is de-energized for the

whole time of the task.

Never bridge or deactivate fuses.

Always keep moisture away from energized parts because it can cause a short

circuit.

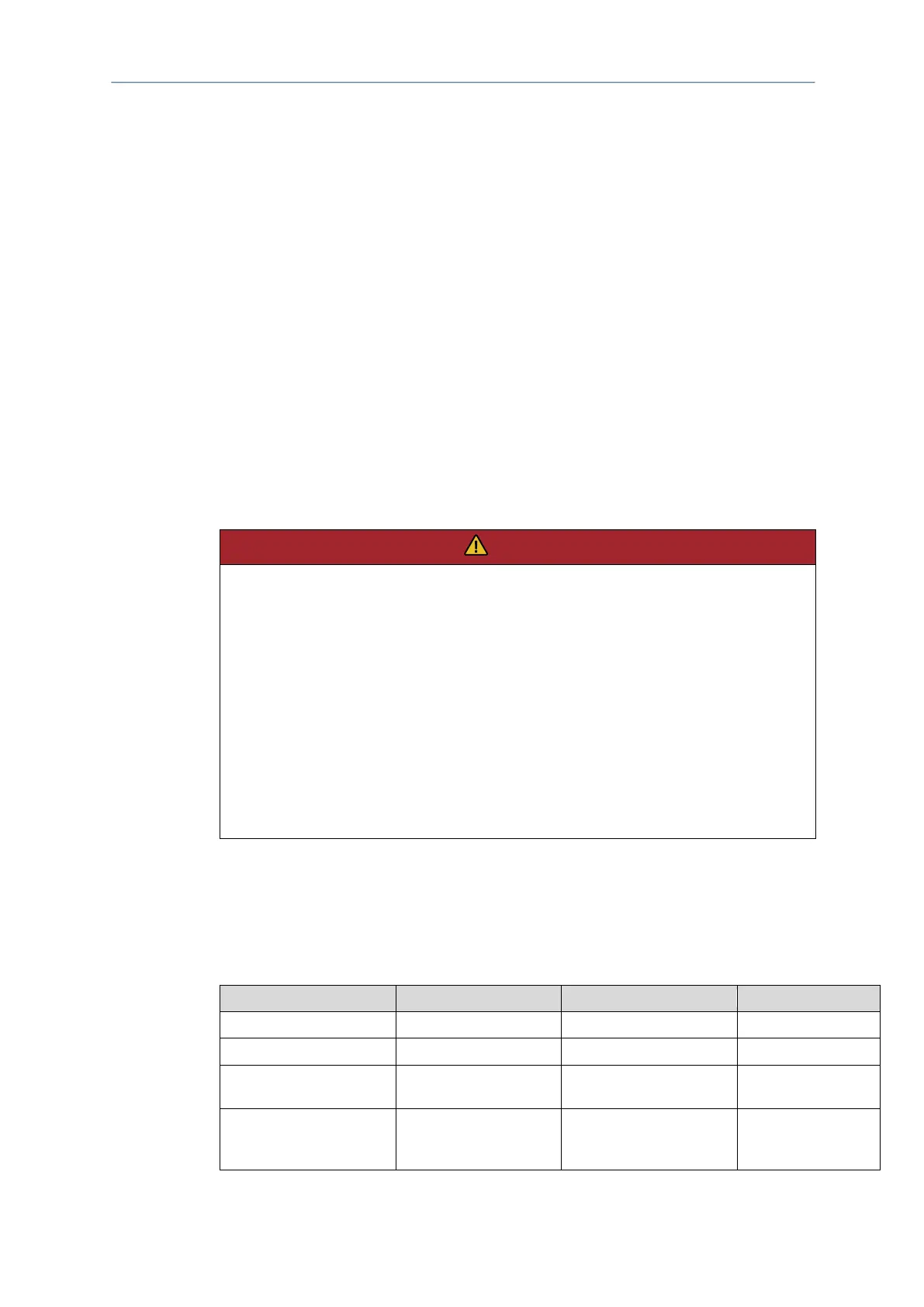

7.2 Maintenance schedule

The following tables provide an overview of the maintenance tasks that have to be

performed by properly trained personnel.

After 100 operating

hours

When the extraction

power weakens

noticeably.

Replacing the HEPA filter

See user manual of

the extraction system

Table 6: Maintenance schedule for the maintenance personnel of the operator

Loading...

Loading...