MAN B&W 5.18

Page 6 of 8

MAN Diesel

198 53 221.5MAN B&W 70-26 engines

20- 0ITCH

#OORDINATED

#ONTROL

3YSTEM

(ANDLES

INTERFACE

$UPLICATEDæ.ETWORK

%NGINE

SAFETY

SYSTEM

%NGINEæSPEED

3YSTEMæFAILUREæALARMæ,OADæREDUCTIONæ,OADæREDæ#ANCELæALARM

%NGINEæOVERLOADæMAXæLOAD

34/0

'OVERNORæLIMITERæCANCEL

20- 0ITCH

)

3TART3TOP3LOWæTURNINGæ3TARTæBLOCKINGæ2EMOTE,OCAL

!HEAD

!STERN

2EMOTE,OCAL

&UELæ)NDEX

#HARGEæ!IRæ0RESS

4ERMINALSæFOR

PROPELLER

MONITORING

SENSORS

0

)

0ITCH

0ITCHæ3ET

,OCALæENGINEæ

CONTROL

3PEEDæ3ET

0ROPULSION

#ONTROL

3YSTEM

"RIDGEæ7ING

3HUTæDOWNæ3HUTæDOWNæRESETCANCEL

0ROPELLERæ0ITCH

#LOSEDæ,OOP

#ONTROLæ"OX

0ITCH

/PERATOR

0ANELæ

/PERATOR

0ANEL

/PERATOR

0ANEL

"ACKUPæSELECTED

3HAFTæ'ENERATOR

æ0-3

!UXILIARYæ#ONTROL

%QUIPMENT

3HIPS

!LARM

3YSTEM

%3

-AINæ#ONTROLæ3TATION

#ENTER

"RIDGEæ7ING

"5æ"ACK5Pæ#ONTROL

"RIDGE

%NGINEæ#ONTROLæ2OOM

%NGINEæ2OOM

34/0

0

)

0

)

34!24

/PERATOR

0ANELæ

20- 0ITCH 20- 0ITCH

%3æ%MERGENCYæ3TOP

%3 "5 %3

/PERATOR

0ANEL

/0ç0

4ERMINALSæFOR

ENGINEæMONITORING

SENSORS

34/0

)NæGOVERNOR

'OVERNOR

/6%2

,/!$

178 22 406.1

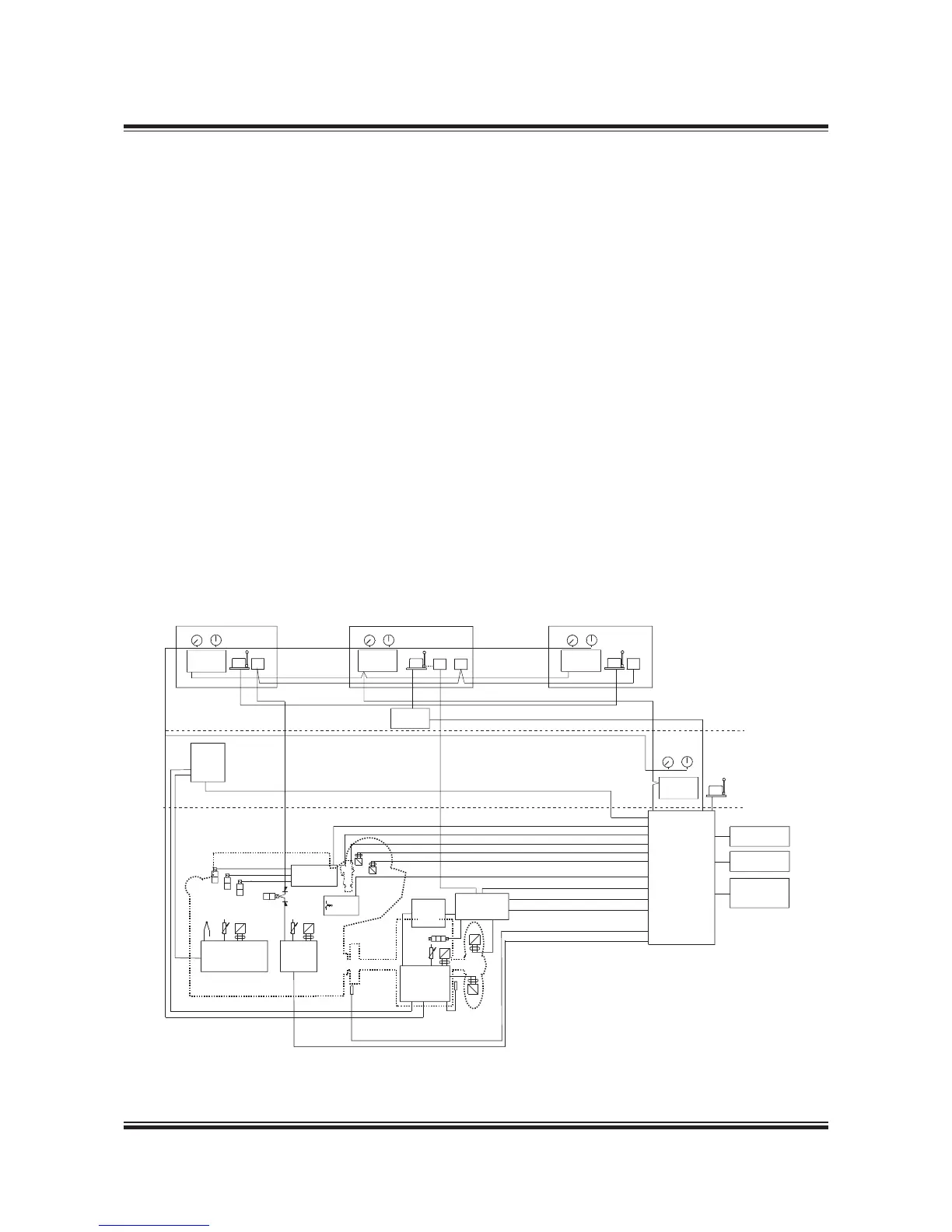

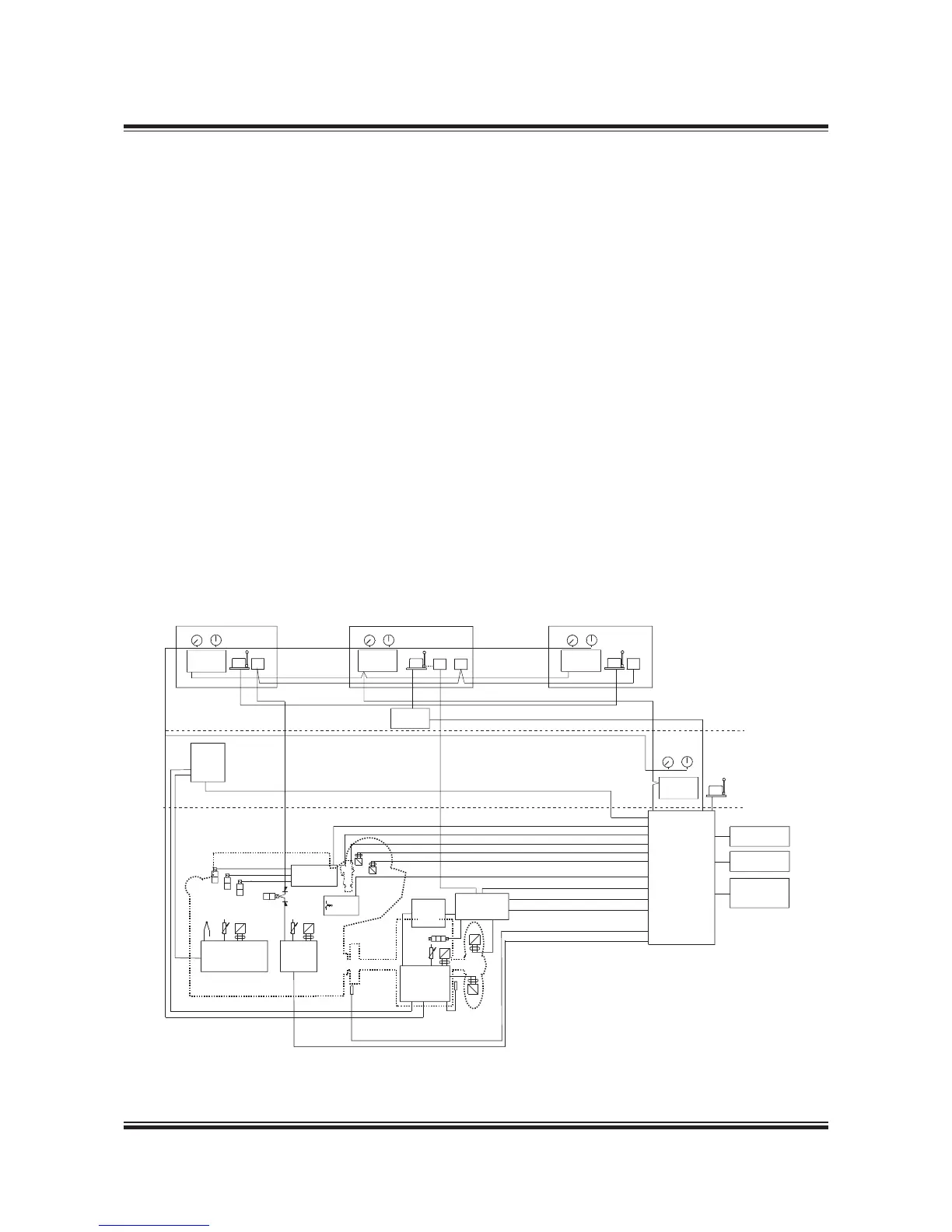

Fig. 5.18.07: MAN Alphatronic 2000 Propulsion Control System

MAN Alphatronic 2000 Propulsion Control

System

MAN Diesel & Turbo’s MAN Alphatronic 2000 Pro-

pulsion Control System (PCS) is designed for con-

trol of propulsion plants based on diesel engines

with CP propellers. The plant could for instance

include tunnel gear with PTO/PTI, PTO gear, mul-

tiple engines on one gearbox as well as multiple

propeller plants.

As shown in Fig. 5.18.07, the propulsion control

system comprises a computer controlled system

with interconnections between control stations via

a redundant bus and a hard wired backup control

system for direct pitch control at constant shaft

speed.

The computer controlled system contains func-

tions for:

• Machinery control of engine start/stop, engine

load limits and possible gear clutches.

• Thrust control with optimization of propeller

pitch and shaft speed. Selection of combina-

tor, constant speed or separate thrust mode is

possible. The rates of changes are controlled to

ensure smooth manoeuvres and avoidance of

propeller cavitation.

• A Load control function protects the engine

against overload. The load control function con-

tains a scavenge air smoke limiter, a load pro-

gramme for avoidance of high thermal stresses

in the engine, an automatic load reduction and

an engineer controlled limitation of maximum

load.

• Functions for transfer of responsibility be-

tween the local control stand, engine control

room and control locations on the bridge are

incorporated in the system.

Loading...

Loading...