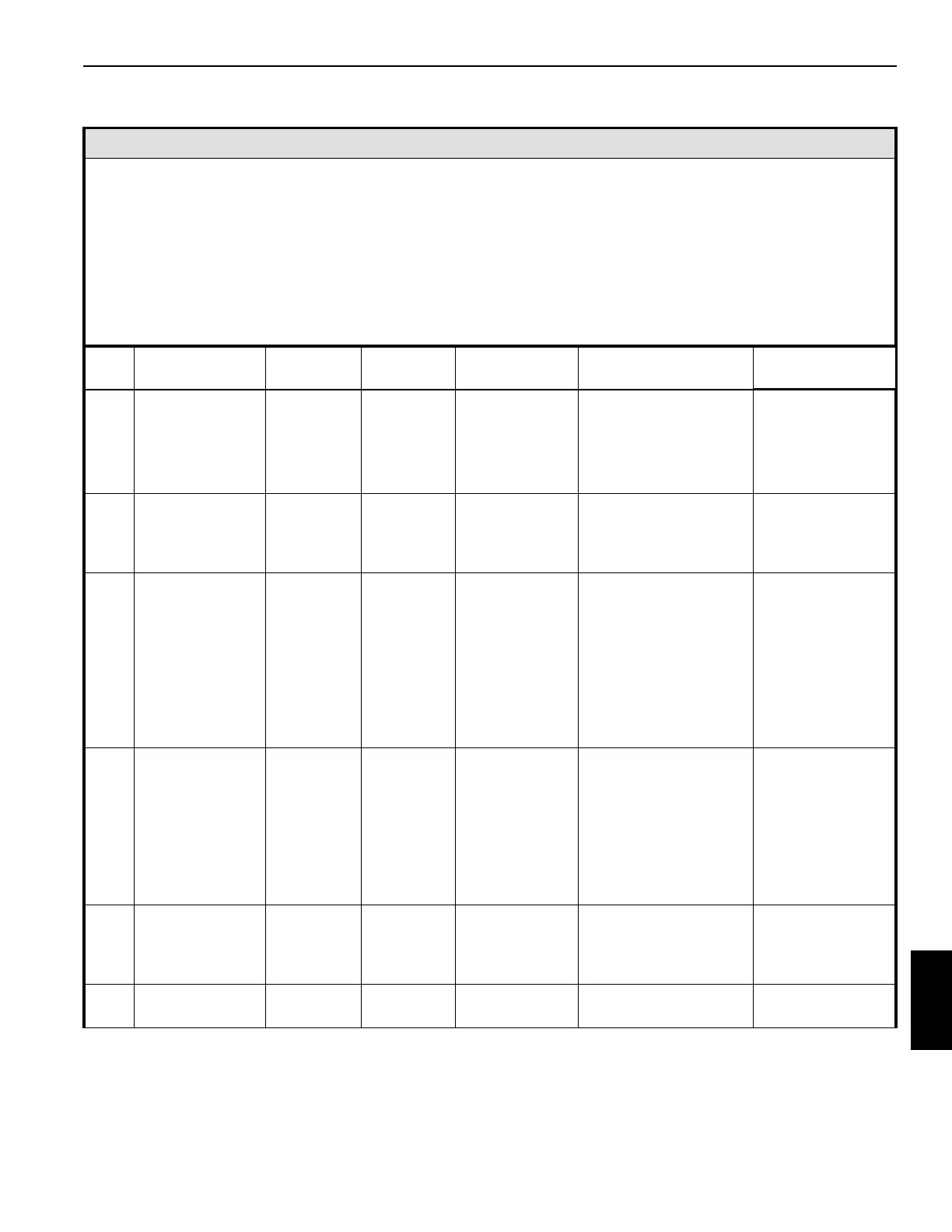

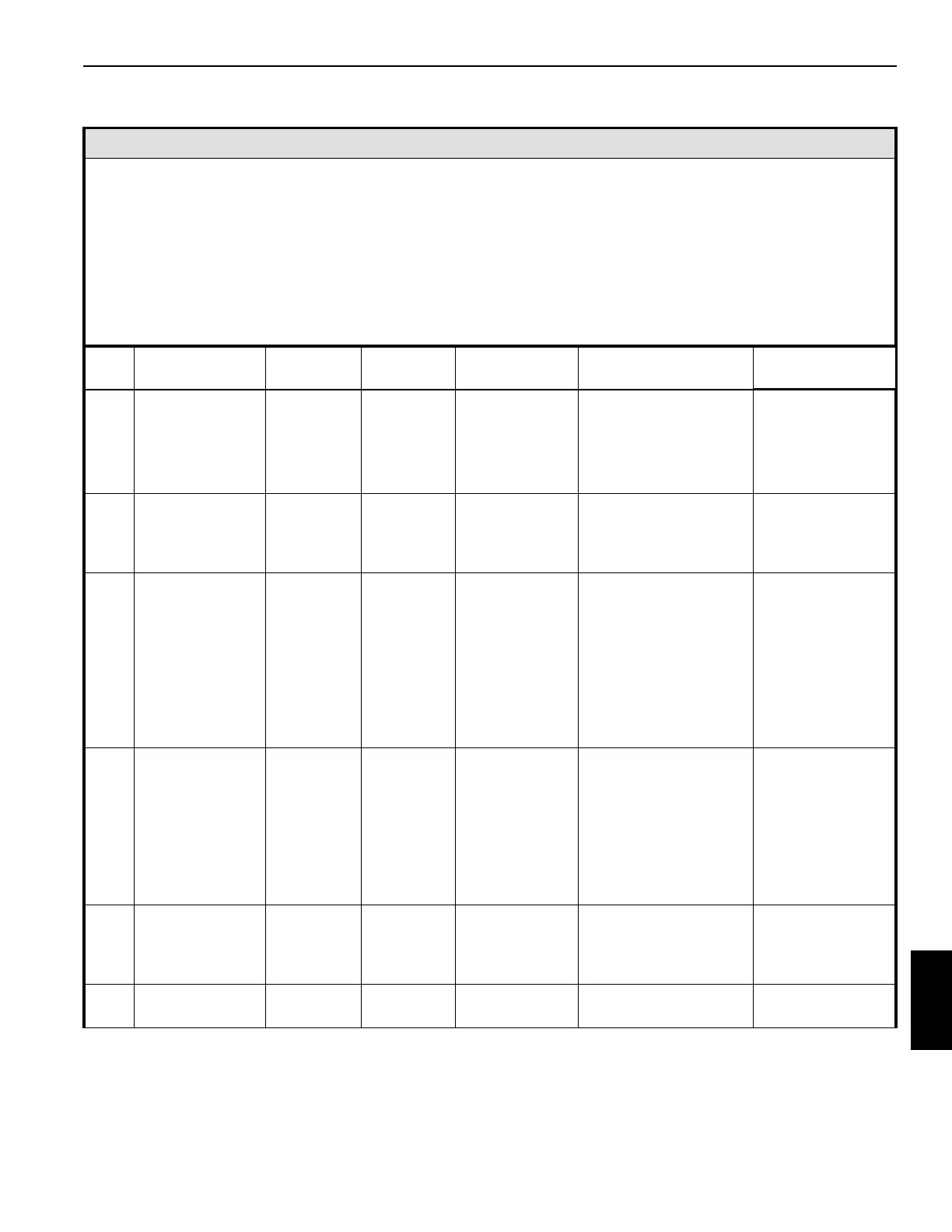

9-21

GRT8100 SERVICE MANUAL LUBRICATION

Published 3/26/2018, Control # 596-05

Boom (Continued)

NOTE: Crane Setup: Machine shall be set up on firm level surface with fully extended outriggers and minimum 9979 kg

(22,000 lb) counterweight installed. Ensure crane is level.

• Boom must be directly over the front with house lock engaged.

• Set boom angle at zero degrees (0°).

• Do not exceed 35 m (115 ft) boom length in Auto Mode A.

• Do not exceed 27.4 m (90 ft) boom length in Auto Mode B.

• All lubrication points can be accessed by operating crane in the 0001 RCL mode using A or B boom configurations.

CAUTION: Do not operate crane in RCL bypass to lubricate the boom.

Item

Lube Point

Description

Figure No.

Approved

Lubricant

Lube Capacity Lube Interval Application

83

Telescope

Cylinder Wear

Pads

Figure 9-12 L Coat thoroughly

Apply grease at

assembly or tear-down.

• 12 places

• Extend boom for

access through

holes in side of

sections 3 & 4

84

Internal Side and

Bottom Wear

Pads - Inner

Sections

Figure 9-12

&

Figure 9-13

L

Thoroughly

coat all areas

wear pad

moves on

250 hours/3 months 23 locations

85A

Boom Section

Rear Upper

Wear Pads - Tele

1

Figure 9-12 L

Thoroughly

coat all areas

the wear pad

moves on

50 hours/1 week

• 2 locations

• Extend Tele 1 to

17.6 meters

(57.8 FT) and

20.7 Meters

(67.8 FT) so

access holes

align with the

grease fittings.

85B

Boom Section

Rear Upper

Wear Pads - Tele

2 - 4

Figure 9-12

&

Figure 9-13

L

Thoroughly

coat all areas

wear pad

moves on

50 hours/1 week

• 6 locations

• Extend Tele 2 to

38.1 Meters

(124.9 FT) so

the access

holes align with

the grease

fittings.

86

Boom Section

Lower & Upper

Wear Pads

Figure 9-12

&

Figure 9-13

L

Thoroughly

coat all areas

wear pad

moves on

50 hours/1 week 12 locations

87

Extend Cable

Sheave

Figure 9-12 A

Until grease

extrudes

250 hours or 3 months 6 locations

Loading...

Loading...