2-67

GRT9165 SERVICE MANUAL HYDRAULIC SYSTEM

Published 10-01-2020 Control # 699-00

more than 100 mA there may other issues in the

circuit.

b. Once the pressure is achieved make sure to “Save

active to customer” and “Save active to factory.”

Stop the engine.

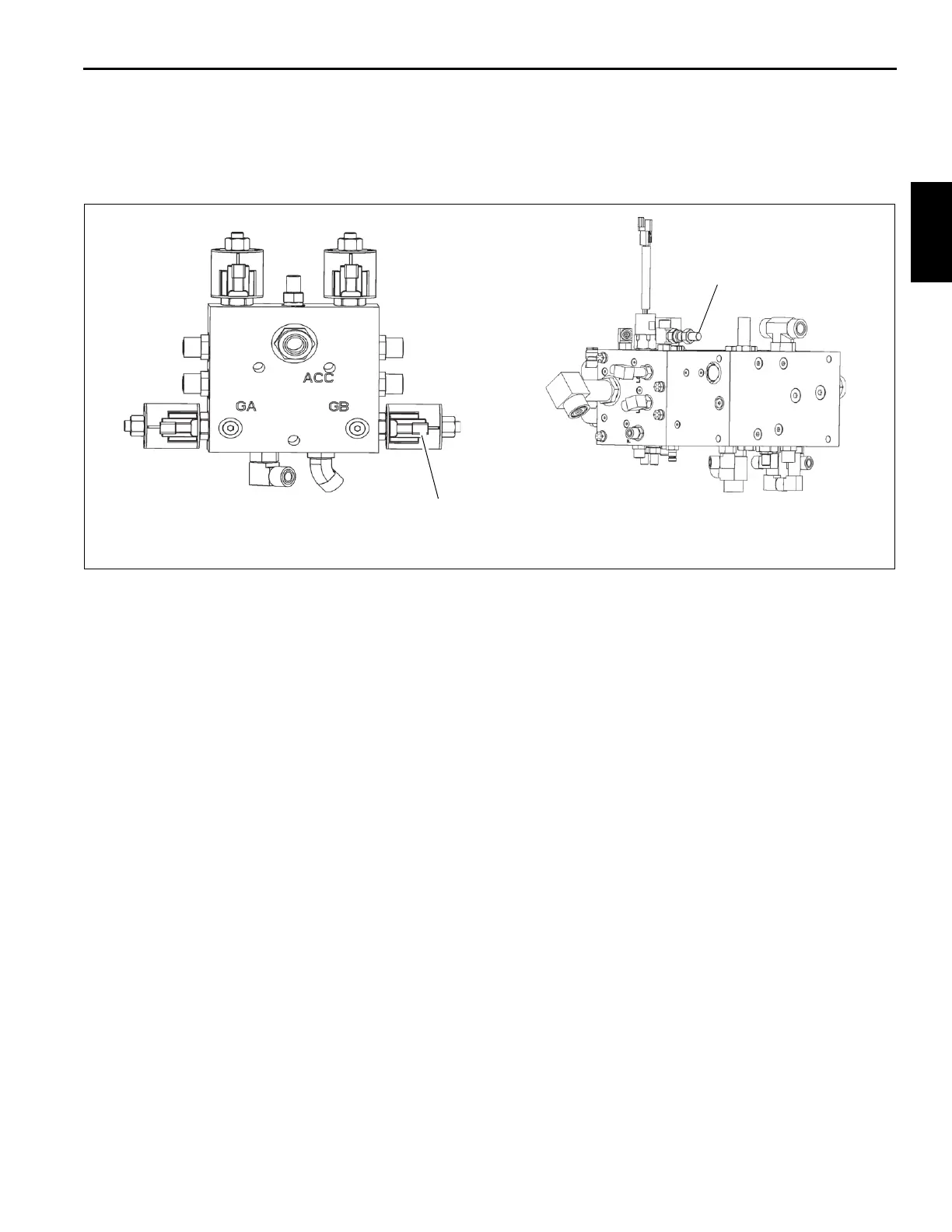

Suspension Raise Pressure

1. On suspension valve manifold (Figure 2-34), unplug the

coil on valve inlet port P. Start the engine and idle.

Operate the suspension fill function and hold. The

reading at LS port (1, Figure 2-33) should read the value

cited in Table 2-3. If it is not, use the service tool as

follows to adjust:

a. In the Manitowoc Crane Tool, open Tools > EEprom

> View Parameters > Cabin > Solenoid PWM

Control (carrier) > Pressure Sol – Suspension Raise

Target. In the params row, increase the valve to

increase the pressure or decrease the valve to

decrease the pressure (adjustment by 10 mA

increments is suggested). Make sure to write

column to “active settings”. Repeat this step until the

pressure is achieved. If the value needs adjusted by

more than 100 mA, there may other issues in the

circuit.

b. After the pressure is achieved make sure to “Save

active to customer” and “Save active to factory.”

2. Stop the engine. Plug the inlet coil in on the suspension

valve manifold.

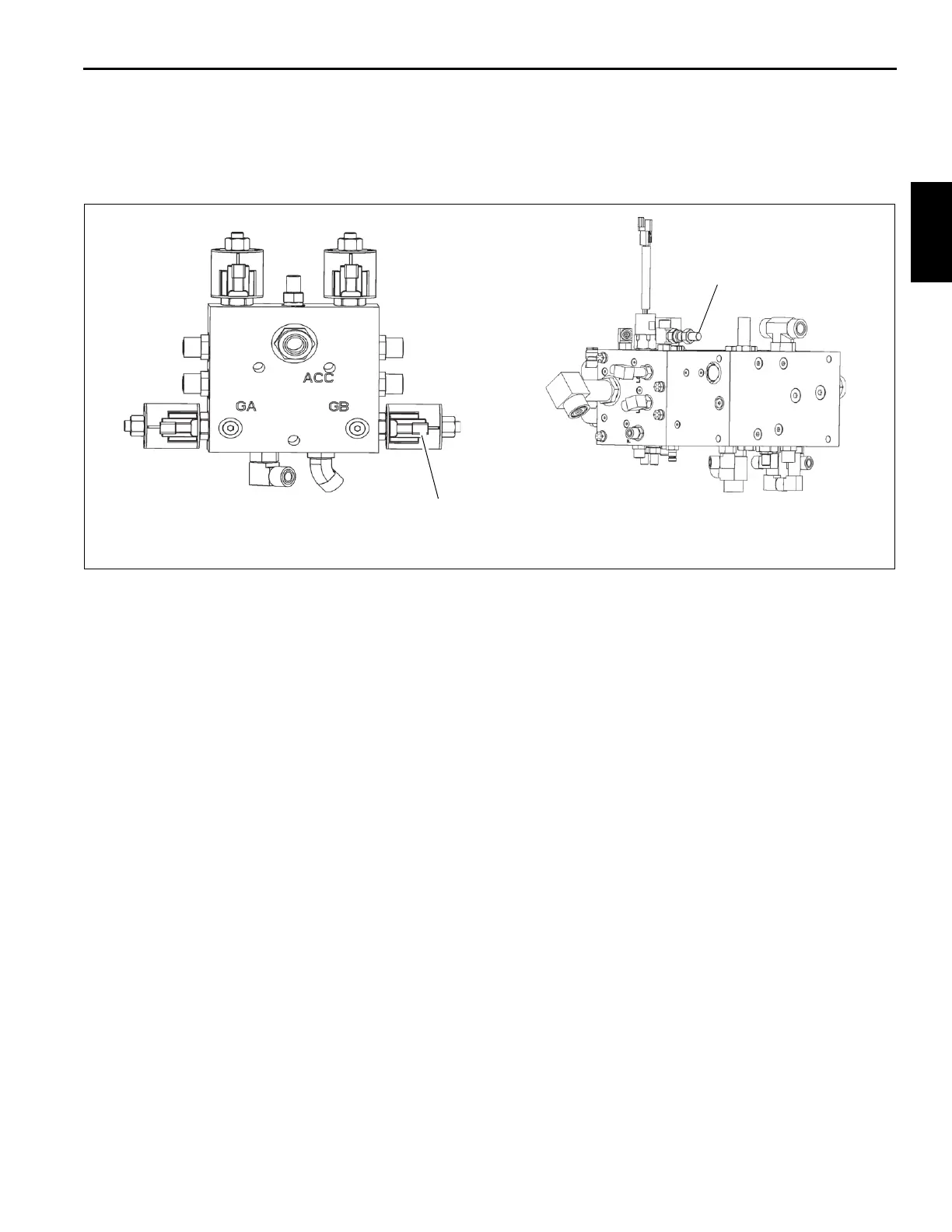

Checking/Setting Park Brake Pressure and

Transmission Fan Max Pressure

1. With the engine off, install a pressure check diagnostic

coupler (such as a Parker PD240) with gauge onto the

diagnostic nipple at the PS port of the main carrier valve

(Figure 2-34).

2. Unplug transmission fan coil from harness (Figure 2-34).

3. Start engine and idle. Release (pressurize) the parking

brake. Read gauge and adjust the pressure reducing

valve (Figure 2-34) “in” to increase or “out” to decrease

to the value cited in Table 2-3.

4. With coil unplugged, and parking brake released, check

fan speed with photo tachometer. Fan speed should the

value cited in Table 2-3. Be sure to have the oil

temperature between 49 to 60°C (120 to 140°F) when

reading and adjusting.

5. Stop the engine. Remove the diagnostic couplers. Plug

fan coil back in to harness.

Adjusting Controller Functions

All controller defaults are set at the factory. If there is an

issue with the crane controller functions, try the following:

• Set all function pressure correctly per the above

procedures

• Adjust the function speed through the CCS control

screens

• Adjust the function control through the CCS control

screen selectable curves

Suspension Valve Manifold

Main Carrier Valve Manifold (Rear)

Unplug this coil to

set suspension

raise pressure

Park Brake/

Reducing Valve

Gauge Port

FIGURE 2-34

10143

10144

Loading...

Loading...