8-7

GRT9165 SERVICE MANUAL UNDERCARRIAGE

Published 10-01-2020 Control # 699-00

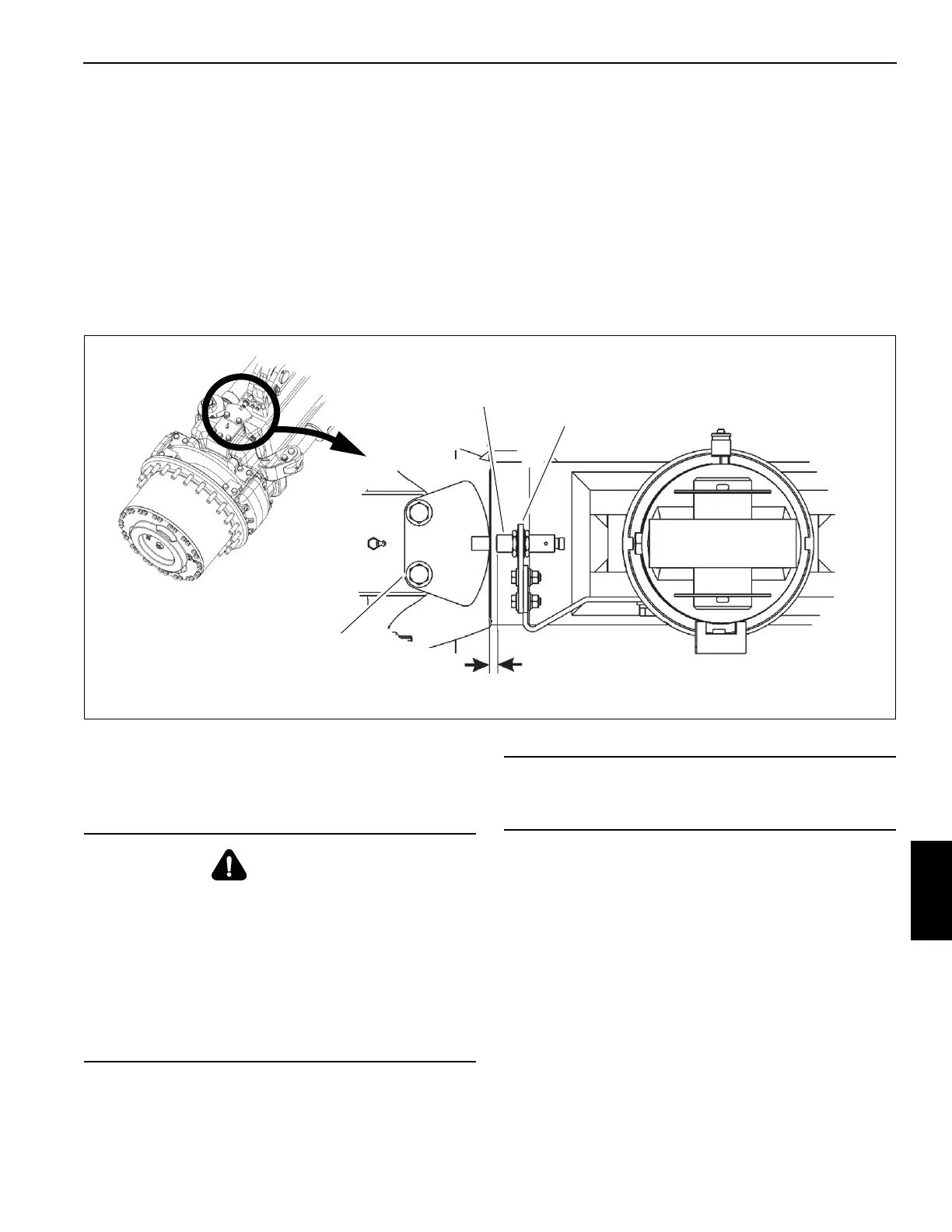

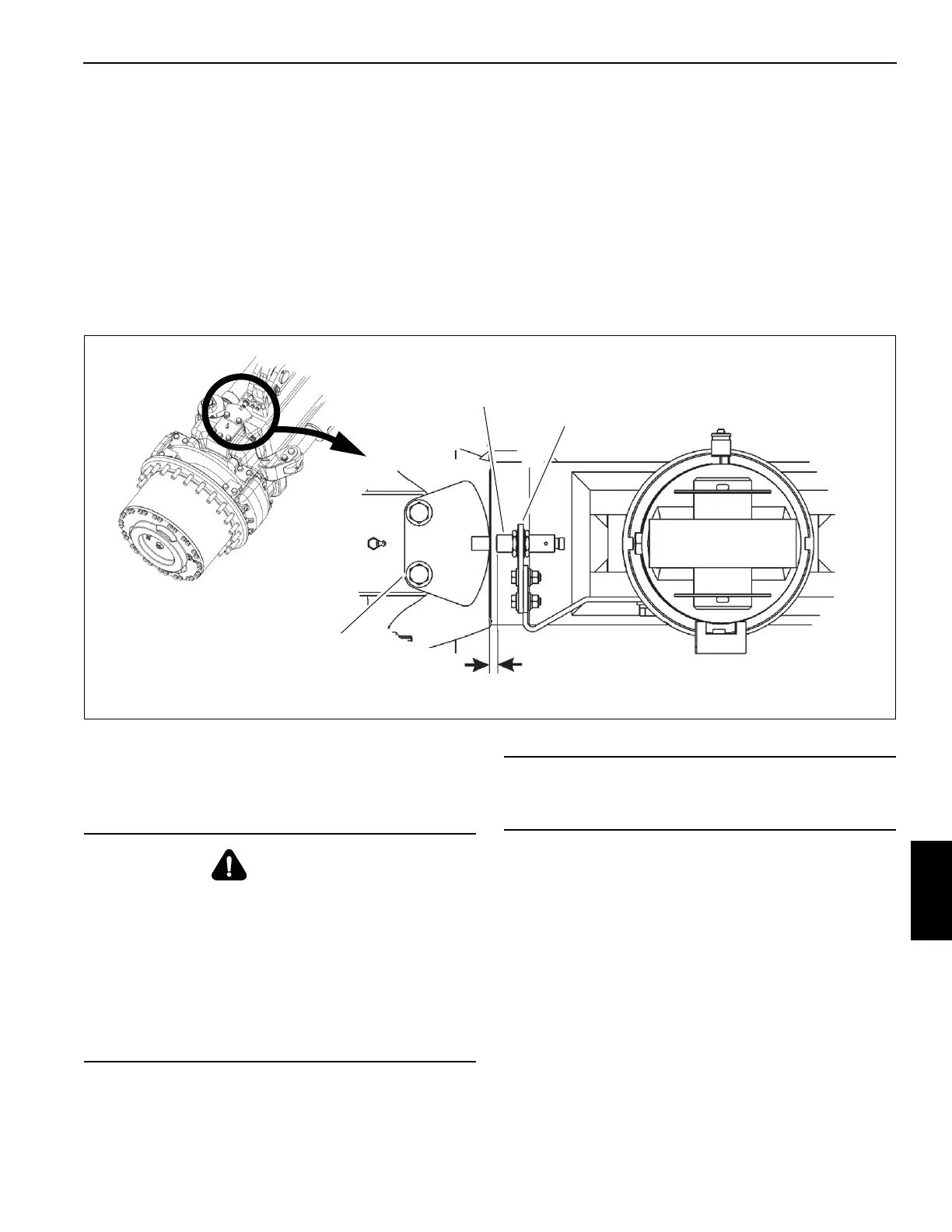

Rear Steer Sensor Adjustment Procedure

Use the following procedure the adjust the rear steer sensor.

A proximity switch on the rear axle senses the position of the

rear wheels. If the wheels are not centered, a signal is sent to

the ODM, which displays the Rear Wheels Not Centered

Indicator in the Alerts area of the ODM. For more information

about steering configurations and the ODM, see the

Operator Manual.

1. Ensure the wheels are straight ahead.

NOTE: When performing rear steer indicator adjustment

using the following steps, refer to Figure 8-6.

2. Slide the proximity switch through hole in the mounting

bracket and secure with nuts and washers.

3. Set face of proximity switch from 4 mm (0.16 in) to 6 mm

(0.24 in) from opening in rear steer sensor plate. Tighten

the fasteners.

4. Turn the rear wheels to verify proper operation. Rear

Wheels Not Centered Light in cab should be out when

rear wheels are centered and the sensor switch is

centered in the slot of the sensor plate. Adjust proximity

switch in or out as needed.

Wheels And Tires

Description

The standard tire size for this unit is 26.5x25-44 ply.

Each wheel assembly (tire and rim) is mounted on the

planetary hub with 24 3/4-16UNF lug nuts.

NOTE: The tire diameters, widths, and weights may vary

slightly depending on the tire manufacturer.

Off-highway tires are designed to operate with a certain

sidewall deflection or bulge. Correct air pressure ensures

prior deflection which, in turn, ensures proper traction,

flotation, support of load, and prevents excessive flexing of

the tire. Over inflation increases rim stresses, which results

in lowered rim life.

Refer to and adhere to the inflation pressures in the Load

Chart Book in the crane cab.

4 mm to 6 mm

Sensor Plate

Mounting Bracket

Proximity Switch

FIGURE 8-6

(0.16 in to 0.24 in)

10225

10226

WARNING

Possible equipment damage and/or

personal injury!

Driving the crane with a tire under inflated at 80% or less

of its recommended pressure can cause the wheel and/or

tire to fail. Per OSHA Standard 1910.177(f)(2)(i), when a

tire has been driven under inflated at 80% or less of its

recommended pressure, it must first be completely

deflated, removed from the axle, disassembled, and

inspected before re-inflation.

CAUTION

Do not mix tires or rims from different manufacturers.

Vehicle stability can be affected.

Loading...

Loading...