7-29

GRT9165 SERVICE MANUAL POWER TRAIN

Published 10-01-2020 Control # 699-00

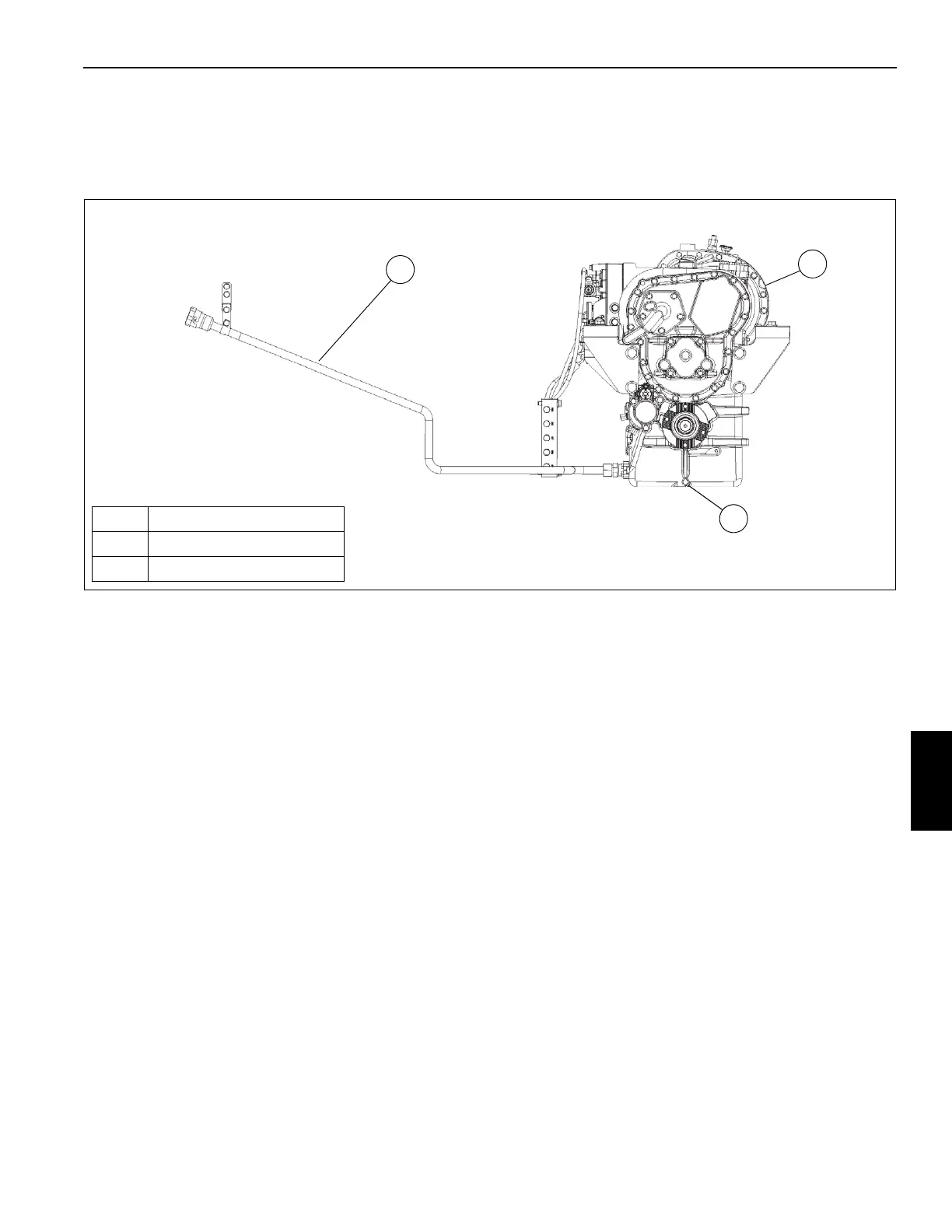

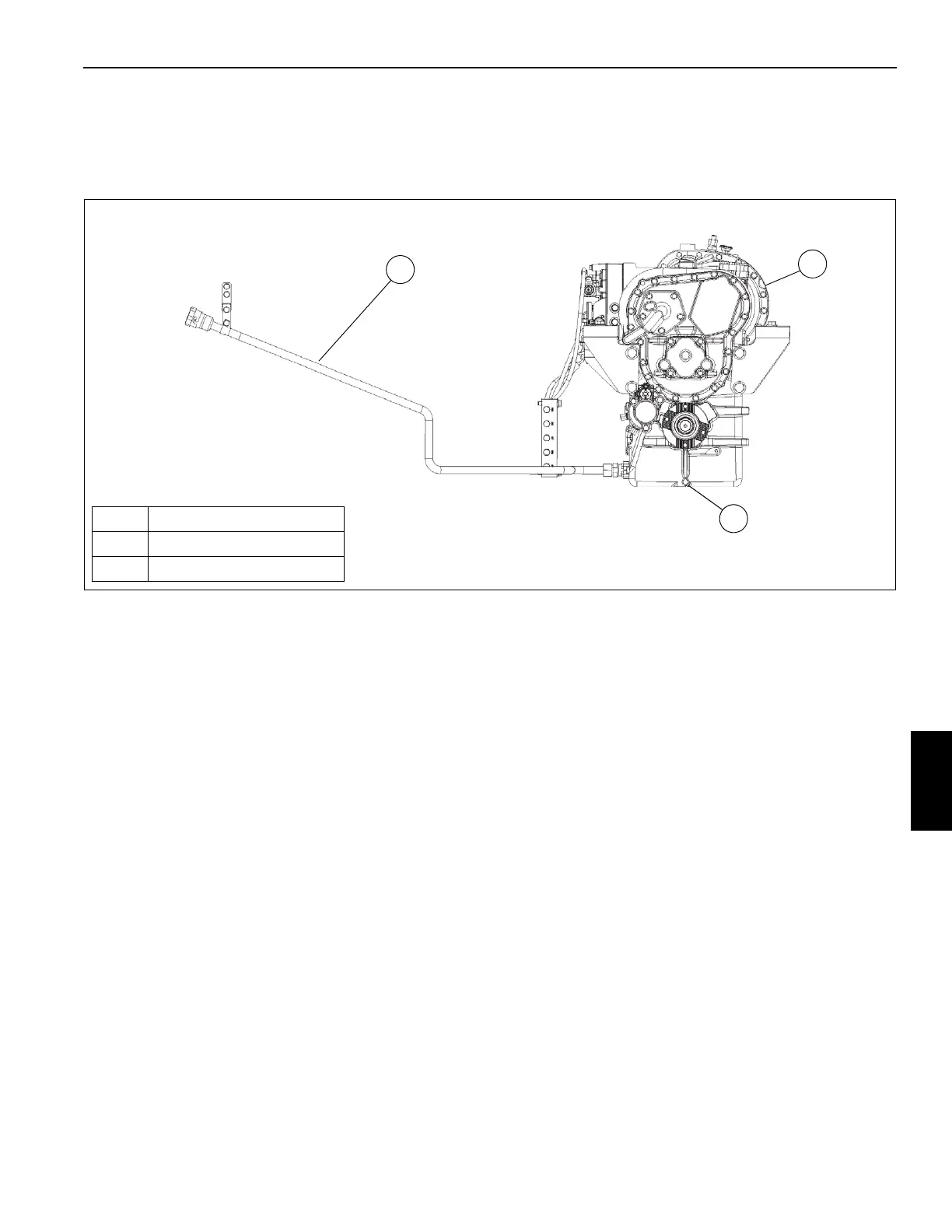

Troubleshooting and Maintenance

For transmission maintenance information, see Maintenance

and Lubrication, page 9-1. For troubleshooting steps, see

Table 7-2.

FIGURE 7-22

1 Transmission

2 Transmission Fluid Dipstick

3 Transmission Drain Plug

2

1

3

Front Looking Back

10211

Loading...

Loading...